5G multilayer circuit board line etching device and method with feeding uniform mixing function

A multi-layer circuit board and etching device technology, which is used in the manufacture of multi-layer circuits, removal of conductive materials by chemical/electrolytic methods, and secondary treatment of printed circuits, to improve side etching, facilitate cleaning operations, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

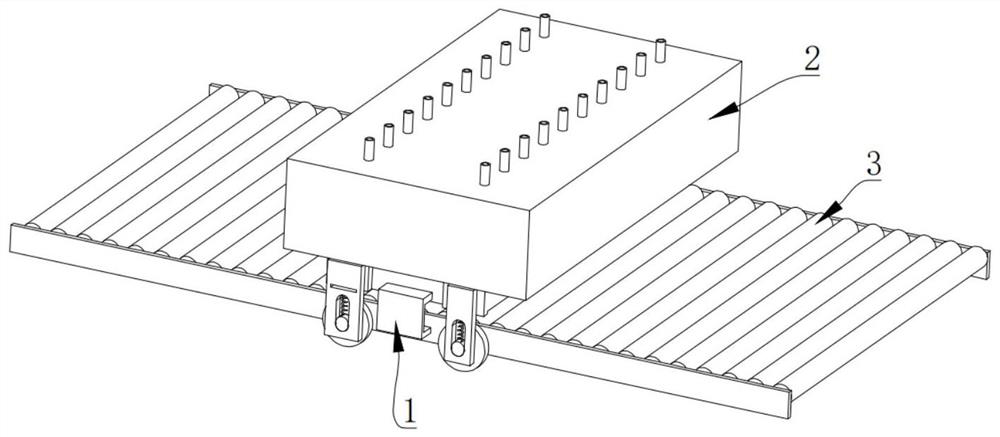

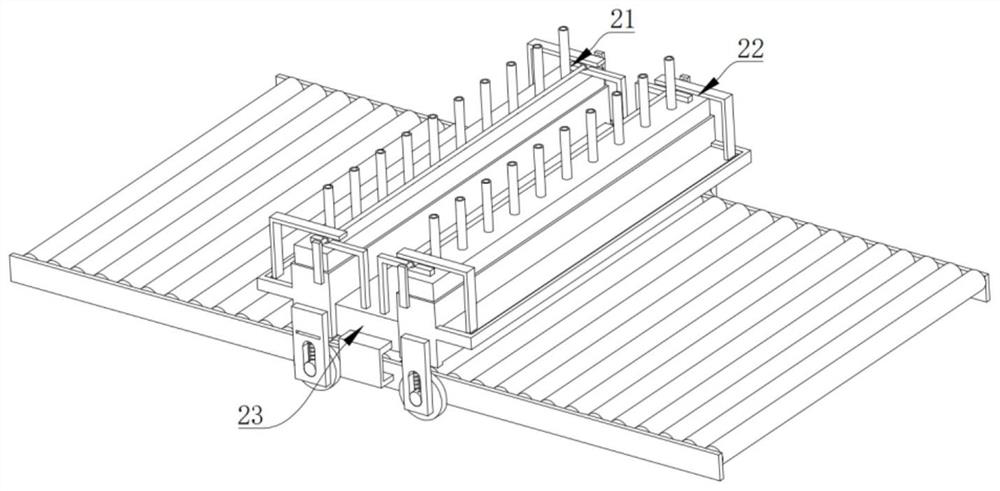

[0037] like figure 1 As shown, the 5G multi-layer circuit board circuit etching device with the function of feeding and mixing, including the rack 1, also includes:

[0038] an erosion assembly 2, the erosion erosion assembly 2 used for etching the plate is installed on the frame 1; and

[0039] A guide assembly 3 , the guide assembly 3 for moving and pushing the plate from the erosion assembly 2 is installed below the erosion erosion assembly 2

[0040] The eroding component 2 pushes out the liquid sprayed onto the surface of the plate back and forth to the forward side, and at the same time pushes out the cleaning liquid sprayed back and forth to both sides of the plate.

[0041] From the above content, it is not difficult to find that in the process of etching the circuit board, since the circuit board is treated with chemicals for too long, it is easy to cause side erosion of the circuit board. rapid removal, resulting in further corrosion of the circuit board caused by ...

Embodiment 2

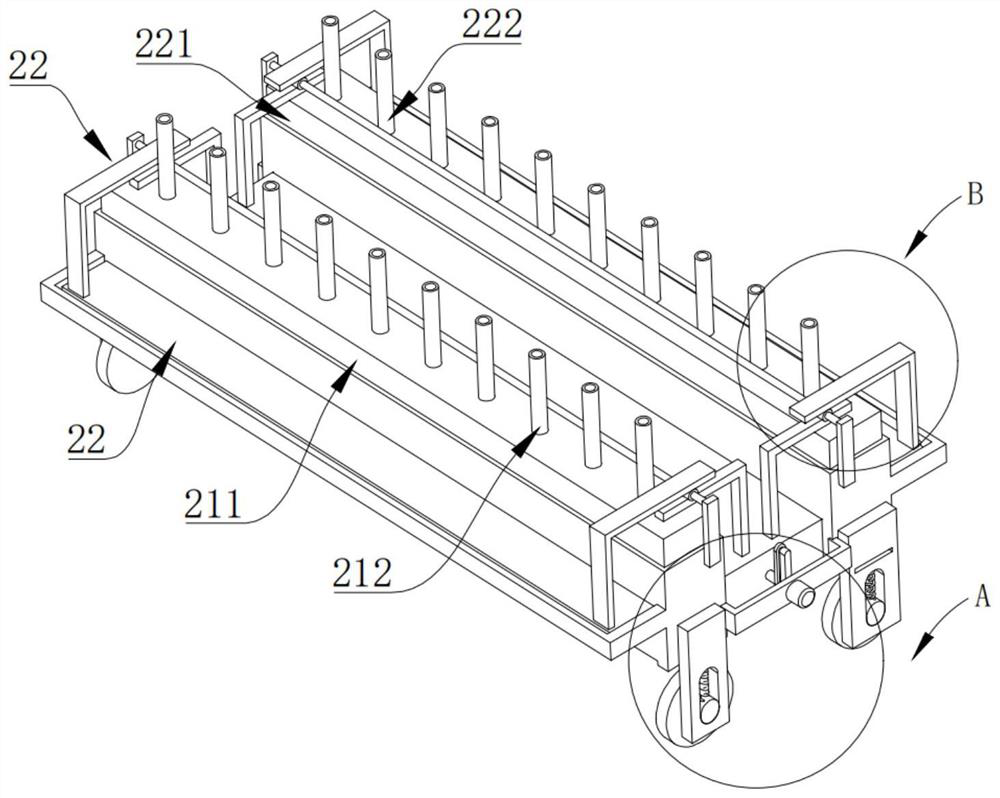

[0073] like Figure 4 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below.

[0074] The difference between the second embodiment and the first embodiment is:

[0075] The device also includes:

[0076] The support assembly 3 used to press the circuit board that reaches the bottom of the erosion erosion assembly 2 on the bottom of the erosion erosion assembly 2;

[0077] The support assembly 3 includes a base 31 installed on the frame 1, a sliding space provided on the base 31, a guide 32 slidably installed in the sliding space, and elastically connecting the guide 32 with the sliding space. The spring 33 and the guide wheel 34 installed on one side of the guide member 32 .

[0078] Through the cooperation between the guide wheel 34 and the spring 33, the guide wheel can be ...

Embodiment 3

[0080] The present invention also provides a 5G multi-layer circuit board circuit etching method with the function of uniform mixing of feeding materials, which is characterized in that it includes the following steps:

[0081] Step 1: Guide the plate, send the plate to be etched through the guide component 1 to the bottom of the etching component 2, and the supporting component 3 supports the plate to be close to the etching component 2;

[0082] Step 2, spraying out the medicine, the medicine spraying member 212 sprays the surface of the plate below the erosion chamber 211, and the injection body 231 pushes the medicine in the erosion cavity 211 to move toward the side of the first pushing out channel 213, from the first push-out channel 213. The medicament pushed out from the pushing channel 213 will process the surface of the plate to be processed;

[0083] Step 3, cleaning treatment, the cleaning liquid spraying member 222 sprays cleaning liquid from the cleaning chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com