Rewiring layer and preparation method thereof

A technology of rewiring layer and seed layer, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problem of easy peeling of fine-pitch rewiring layers, and achieve the effect of preventing peeling and reducing side erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

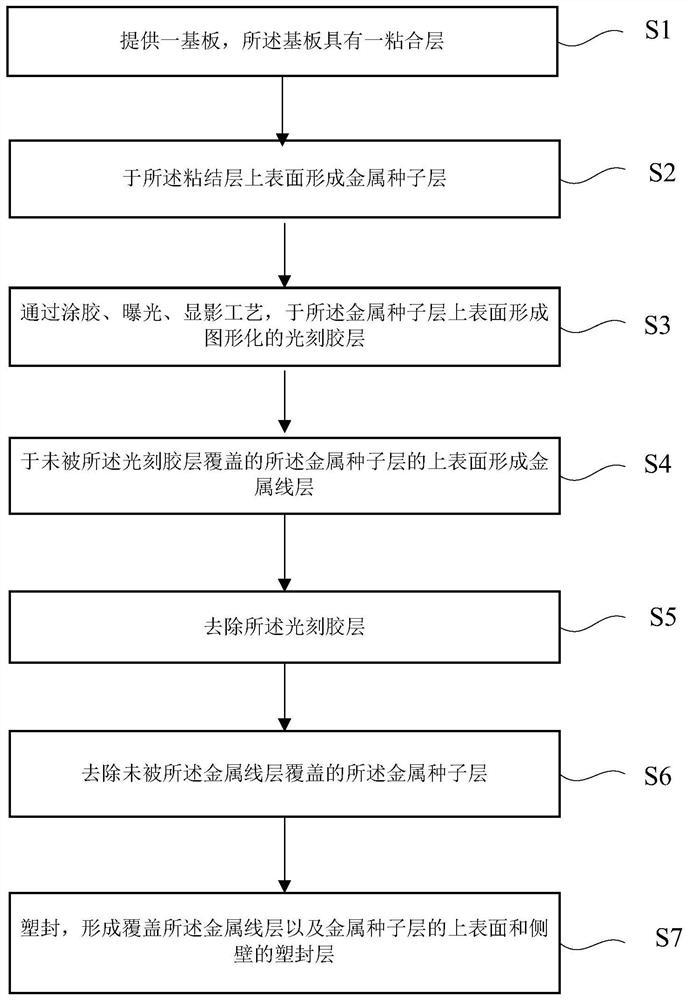

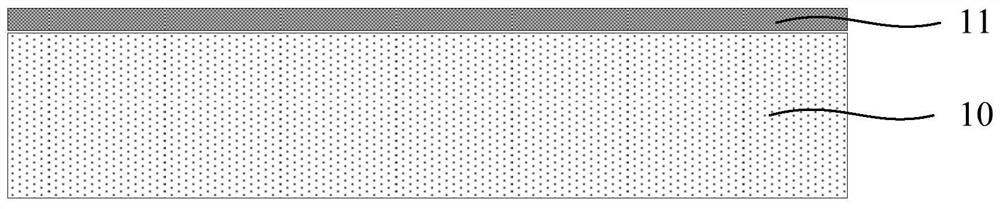

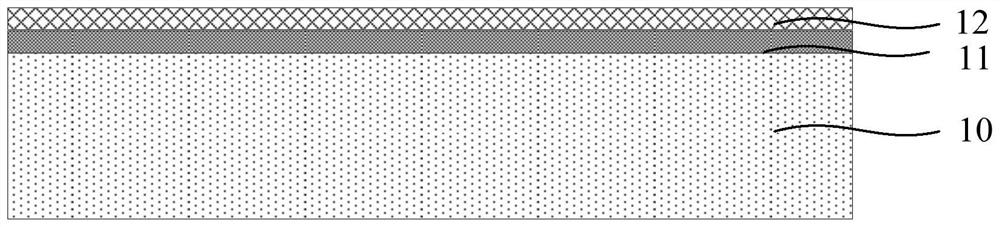

[0048] Such as Figure 1-9 As shown, this embodiment provides a rewiring and a method for preparing a rewiring layer.

[0049] Such as Figure 9 As shown, the rewiring layer at least includes: a metal seed layer 12 , a metal wire layer 14 located on the upper surface of the metal seed layer 11 , and a plastic encapsulation layer 15 covering the upper surfaces and side walls of the metal seed layer 12 and the metal wire layer 14 .

[0050] The material of the metal seed layer 12 is copper or aluminum, but must be a single material. This is because wet etching is one of the important procedures for the preparation process of the rewiring layer, and the etchant has different etching rates for different metals. If two or more metals are used to prepare the metal seed layer, multiple wet etching is required, and due to the isotropy of etching, it will cause side etching, thereby reducing the connection area between the metal line layer and the substrate. This leads to the peelin...

Embodiment 2

[0082] This embodiment provides a method for preparing a rewiring layer.

[0083] This embodiment adopts a process similar to that of Embodiment 1. The difference from Embodiment 1 is that the materials of the metal seed layer and the metal wire layer in this embodiment are the same, and copper is used as the metal seed layer and the metal wire layer. .

[0084] Other structures and processes are the same as those in Embodiment 1, and will not be repeated here.

[0085] In this embodiment, the metal line layer and the metal seed layer are made of the same and single material. During the preparation process of the rewiring layer, the side etching phenomenon caused by the isotropy of wet etching can be reduced, thereby improving the rewiring layer. Fabrication yield of the wiring layer.

[0086] In summary, the present invention provides a rewiring layer and a preparation method thereof. The rewiring layer includes: a metal seed layer; a metal wire layer located on the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com