Heat treatment furnace for nanocrystalline magnetic core

A heat treatment furnace and nano-crystal technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of long heat treatment time, low heat treatment efficiency, low utilization rate of exothermic heat energy of magnetic core crystallization, etc., to reduce production costs, Uniform heating and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical solutions, purposes and advantages of the present invention more clearly understood, the present invention will be further explained below with reference to the accompanying drawings and embodiments.

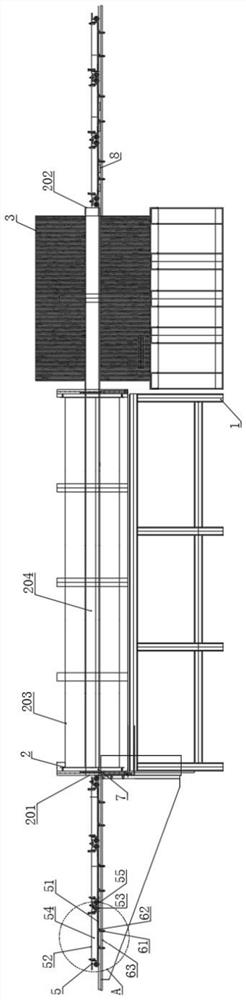

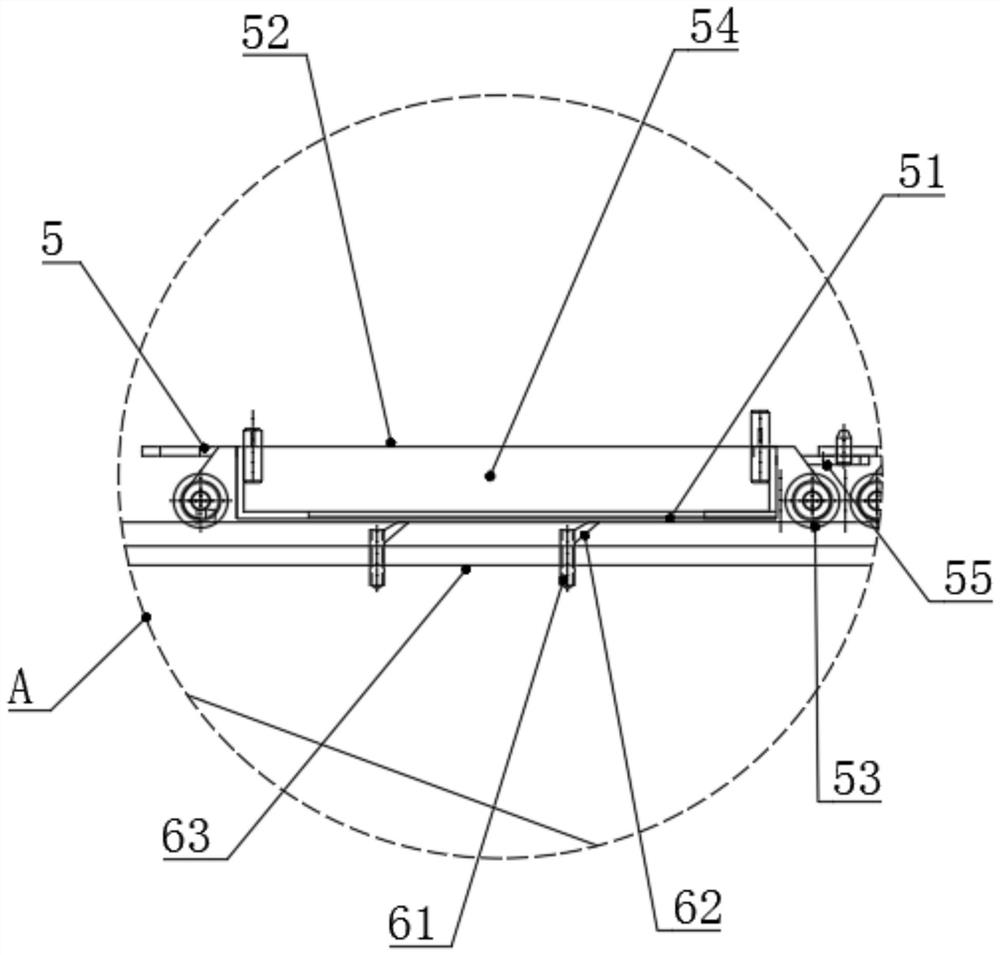

[0029] like Figure 1-2 As shown, the nanocrystalline magnetic core heat treatment furnace includes a frame 1, a heat treatment device 2, a conveying assembly, a magnetizing assembly 3, and a stepping assembly located on the frame 1.

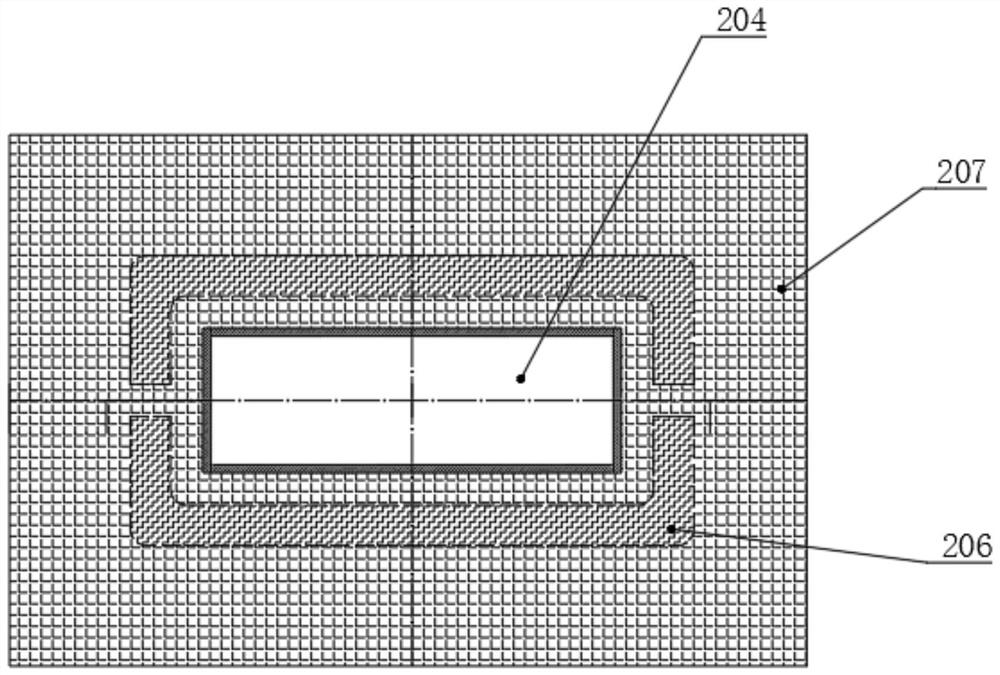

[0030] The heat treatment device 2 is provided with an input port 201 and an output port 202, the input port 201 and the output port 202 are arranged at opposite ends of the heat treatment device 2, and the nanocrystalline magnetic core loaded by the conveying component is between the input port 201 and the output port 202. Make a circular move. The heat treatment device 2 is provided with a heat treatment channel 204 with an inner diameter of the channel only for the conveying component to match and pass, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com