Method and device for producing ammonium bicarbonate by ammonia process decarbonization system

An ammonium bicarbonate, decarbonization technology, applied in separation methods, chemical instruments and methods, ammonium carbonate/acid carbonate, etc., can solve the problems of ammonia escape and low absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

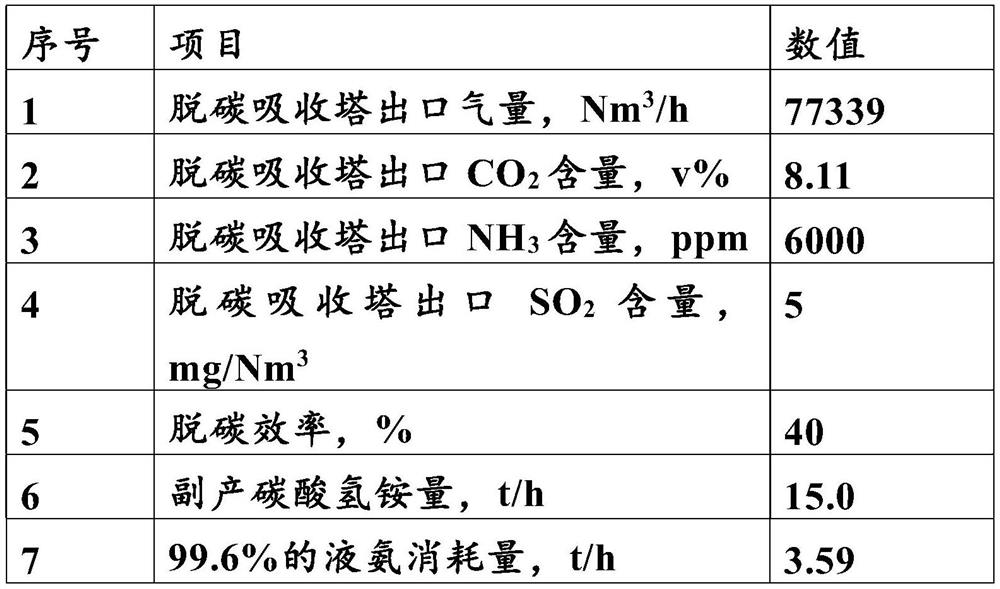

Embodiment 1

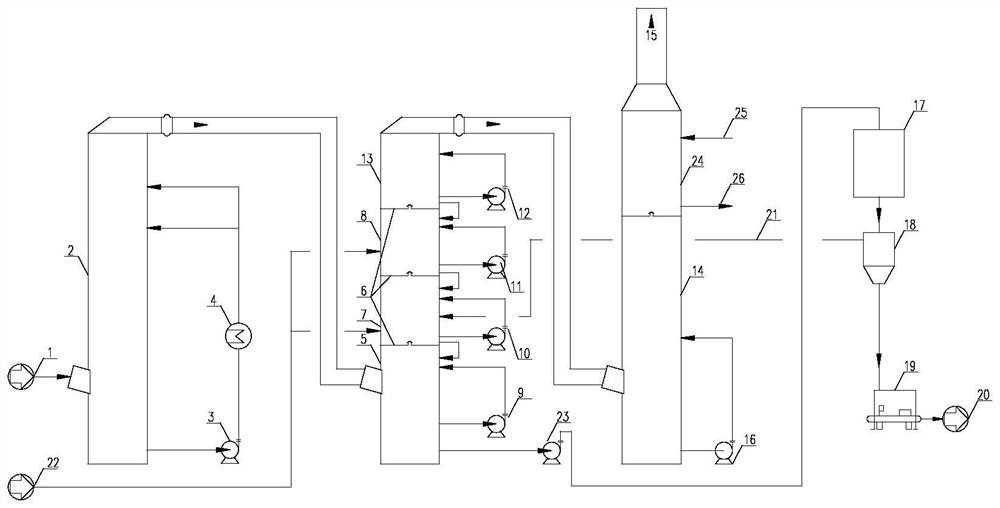

[0042] using as figure 1 The apparatus shown carries out this example. Contains CO 2 The process gas 1 first enters the cooling functional area 2, where the process gas and the circulating liquid are in countercurrent contact to cool down, the circulating liquid is circulated by the cooling circulating pump 3, and the circulating liquid is cooled by the heat exchanger 4. The circulating liquid can be water. During the circulating process, the components entrained by the process gas may enter the circulating liquid, so that the circulating liquid contains components such as ammonium sulfate, a by-product of the previous ammonia desulfurization process.

[0043] The gas cooled to 25°C enters the ammonium bicarbonate generation zone 5 , where the process gas reacts with the circulating liquid in countercurrent contact to generate ammonium bicarbonate, and the circulating liquid is circulated through the circulating pump 9 . The process gas leaving the ammonium bicarbonate gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com