Flame retardant, flame-retardant modified diaphragm, battery and preparation methods of flame retardant and flame-retardant modified diaphragm

A technology of flame retardant and diaphragm, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of poor adhesion and poor cycle stability of batteries, so as to improve the wettability and liquid absorption capacity, and improve cycle stability. The effect of stability and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of flame retardant, its specific preparation method is as follows:

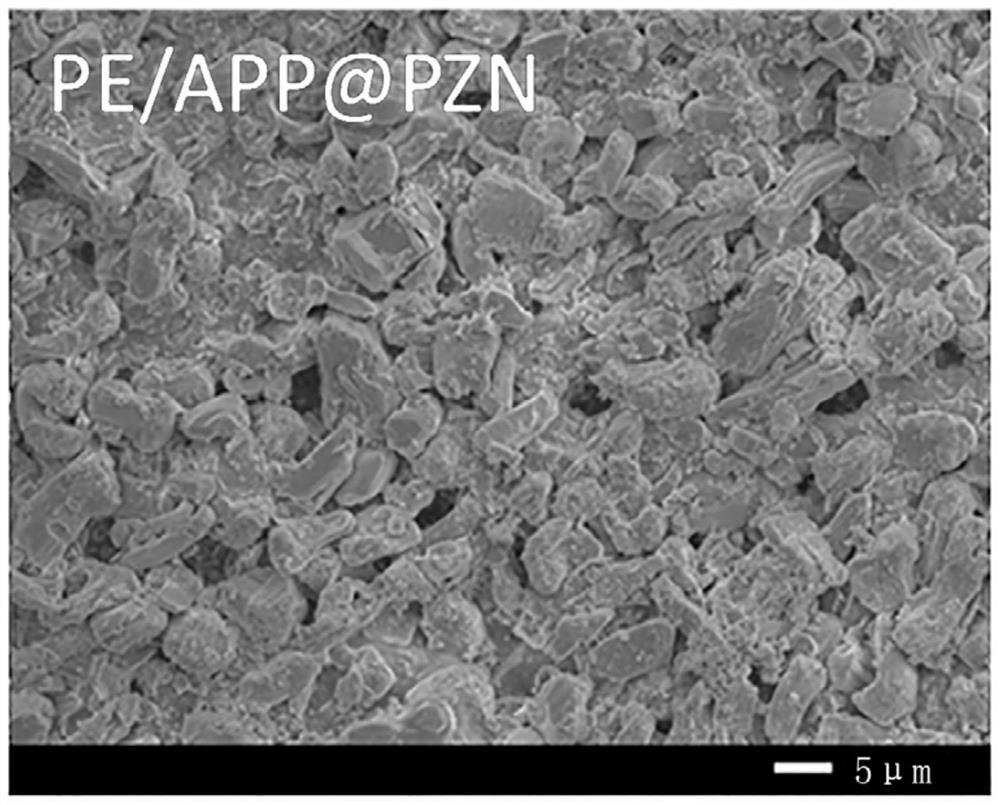

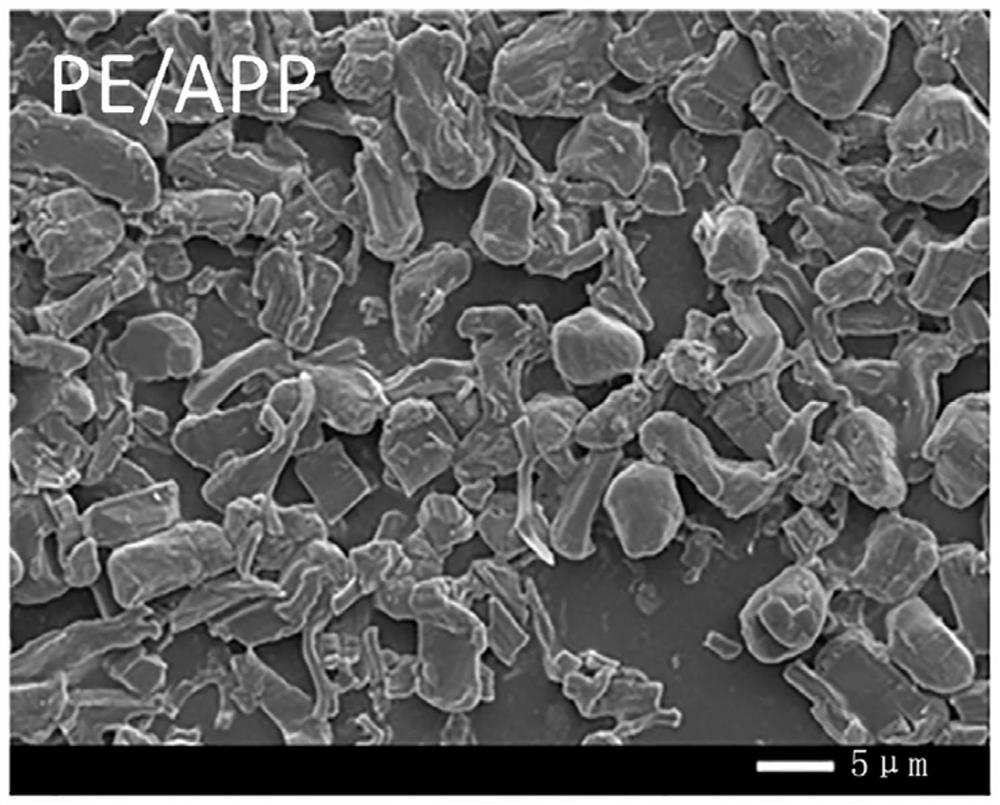

[0040] Take 20g of APP (ammonium polyphosphate) raw material and grind it with a ball mill for 12h, then ultrasonically shake it through a 200-mesh sieve; get 5g of APP after the sieve and 1.2g of 4,4'-dihydroxydiphenyl ether (202g / mol, 0.00594 mol) were dispersed in a 500ml three-necked flask containing 160ml of acetonitrile solvent, and magnetic stirring made it fully dispersed to obtain a mixed solution; 1g of hexachlorocyclotriphosphazene (348g / mol, 0.002874mol) was dissolved in 100ml of acetonitrile to obtain phosphorus Nitrile solution, slowly drop the phosphazene solution into the mixed solution through a constant pressure titration funnel, and add 3 ml of triethylamine to the mixed solution as a pH buffer before adding the phosphazene solution dropwise. The reaction solution was filtered and washed with acetonitrile for more than 3 times. The obtained product was vacuum-dried at 60°C. Af...

Embodiment 2

[0044] A kind of flame retardant, its specific preparation method is as follows:

[0045] Take 20g of APP (ammonium polyphosphate) raw material and grind it with a ball mill for 12h, then ultrasonically vibrate through a 200-mesh sieve; take 4g of sieved APP, Li 3 PO 4 1g and 1.2g of 4,4'-dihydroxydiphenyl ether were dispersed in a 500ml three-necked flask containing 160ml of acetonitrile solvent, and magnetically stirred to make it fully dispersed to obtain a mixed solution; 1g of hexachlorocyclotriphosphazene was dissolved in The phosphazene solution was obtained in 100 ml of acetonitrile, and the phosphazene solution was slowly added dropwise to the mixed solution through a constant pressure titration funnel, and 3 ml of triethylamine was added to the mixed solution as a pH buffer before the dropwise addition of the phosphazene solution. After completion, the reaction solution was kept under reflux at 40°C in a constant temperature magnetic stirrer and stirred continuousl...

Embodiment 3

[0049] A kind of flame retardant, its specific preparation method is as follows:

[0050] Take 20g of APP (ammonium polyphosphate) raw material and grind it with a ball mill for 12h, then ultrasonically shake it through a 200-mesh sieve; take 3.5g of APP, Li 3 PO 4 1.5g and 3.6g of 4,4'-dihydroxydiphenyl ether (202g / mol, 0.01782mol) were dispersed in a 500ml three-necked flask containing 160ml of acetonitrile solvent, and magnetically stirred to fully disperse to obtain a mixed solution; 1g The hexachlorocyclotriphosphazene (348g / mol, 0.002874mol) was dissolved in 100ml acetonitrile to obtain a phosphazene solution, and the phosphazene solution was slowly added dropwise to the mixture through a constant pressure titration funnel, and before the phosphazene solution was added dropwise Add 3 ml of triethylamine to the mixed solution as a pH buffer. After the dropwise addition, keep it in a constant temperature magnetic stirrer to reflux at 40°C, and continue stirring for 6 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com