Environment-friendly anti-blocking type end pipeline for sewage treatment

A sewage treatment and end technology, applied in the field of pipelines, can solve problems affecting the work of conveying liquids, pipeline blockage, burrs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

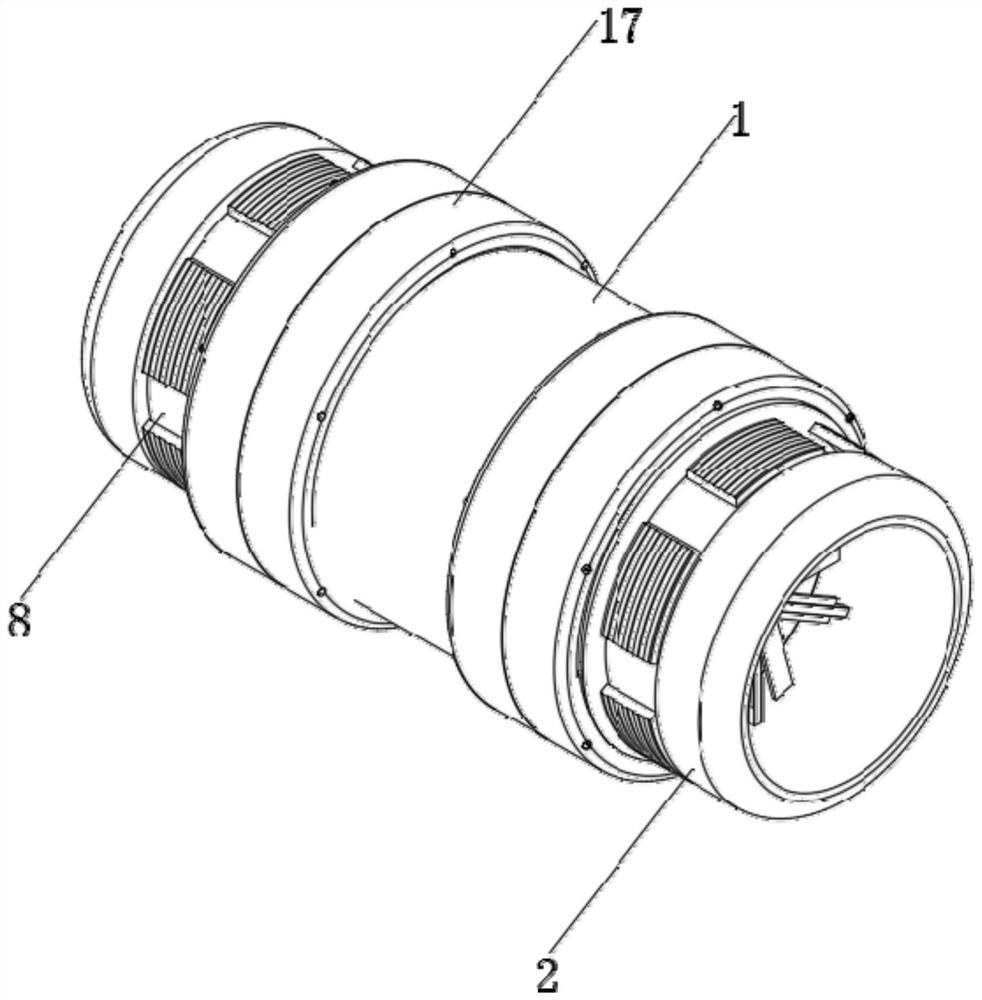

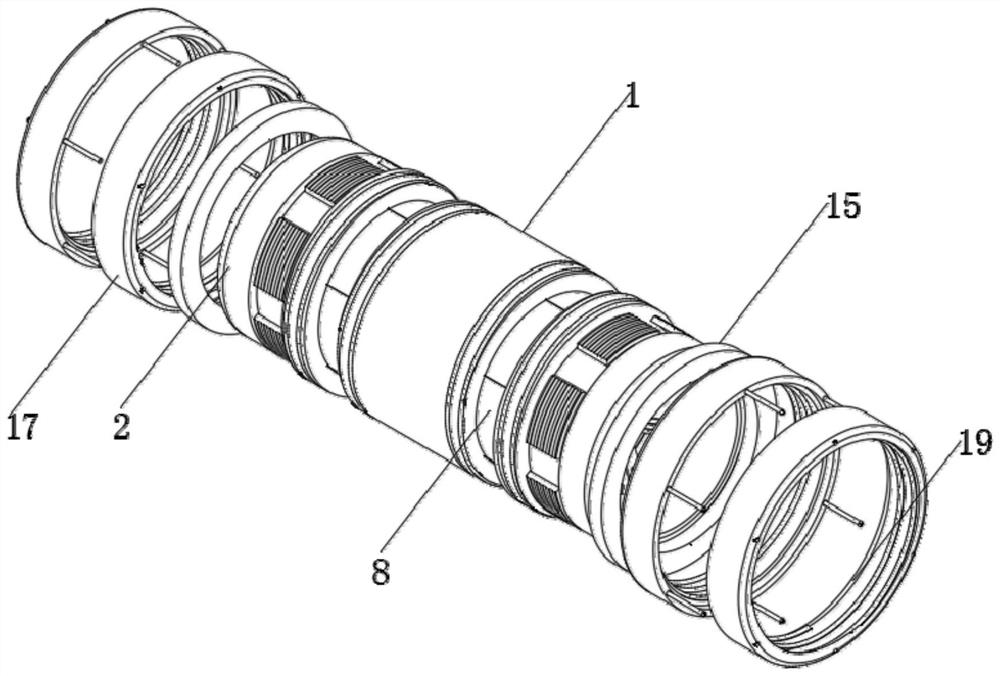

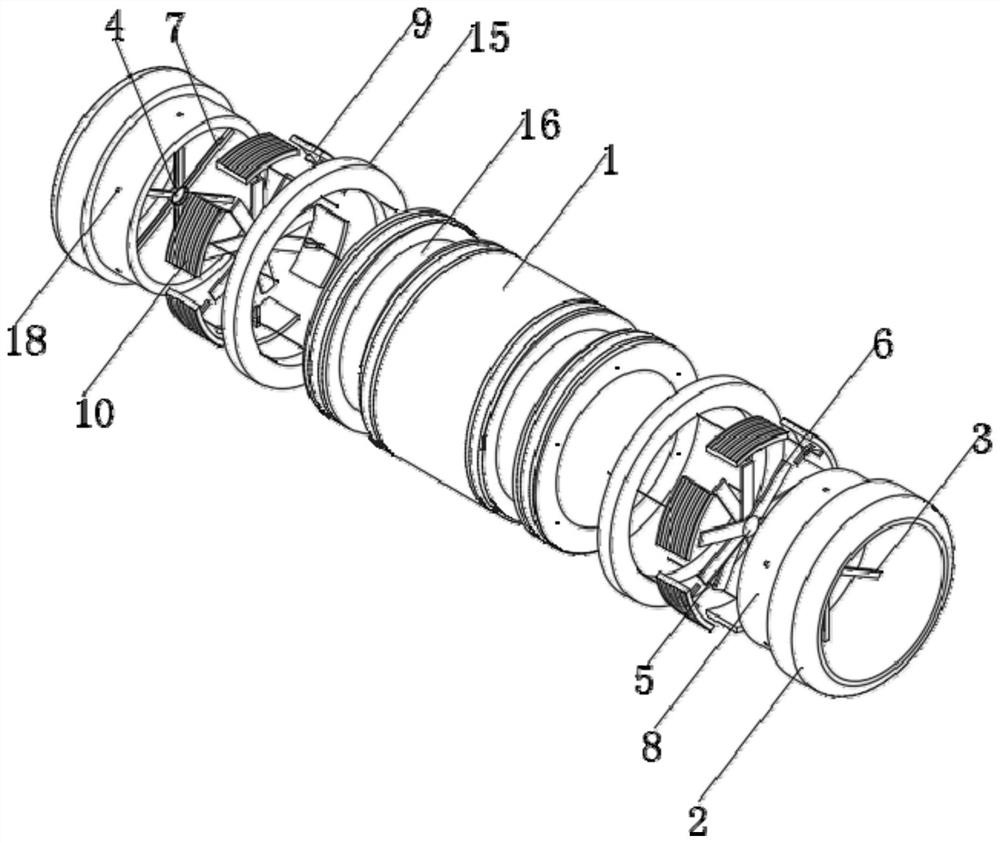

[0027] Example: see Figure 1-5 , The present invention provides a technical solution: an environmental protection and anti-blocking type sewage treatment end pipe, including a main pipe 1, a sub-pipe 2 and an anti-blocking mechanism, the sub-pipe 2 is arranged at both ends of the main pipe 1, and the anti-blocking mechanism is arranged at The inner cavity of the auxiliary pipe 2.

[0028] The anti-blocking mechanism includes a force bar 3, a plug ring 4, a stainless steel shaft 5, an impact fan blade 6 and a friction groove 7. The force bar 3 is equidistantly arranged on the inner wall of the auxiliary pipe 2, and the outer wall of the plug ring 4 is connected to the receiving One end of the force bar 3 is fixedly connected, the stainless steel shaft 5 is arranged in the inner cavity of the plug ring 4, the impact fan blade 6 is arranged on the outer wall of the stainless steel shaft 4, the friction groove 7 is opened on the side of the force bar 3, and the force bar 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com