Variable compression ratio mechanism for self-control adjustment gasoline engine

A compression ratio, gasoline engine technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as mechanical structure difficulties and maintenance difficulties, and achieve the effects of avoiding knocking, simple mechanism principles, and convenient manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

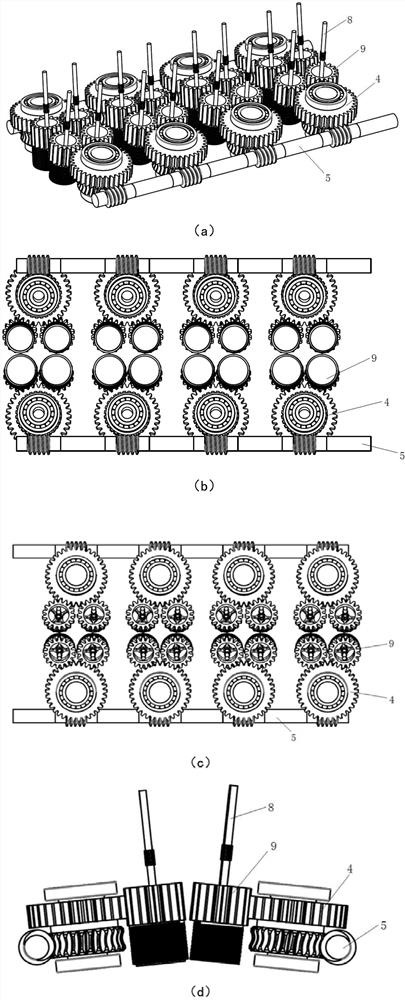

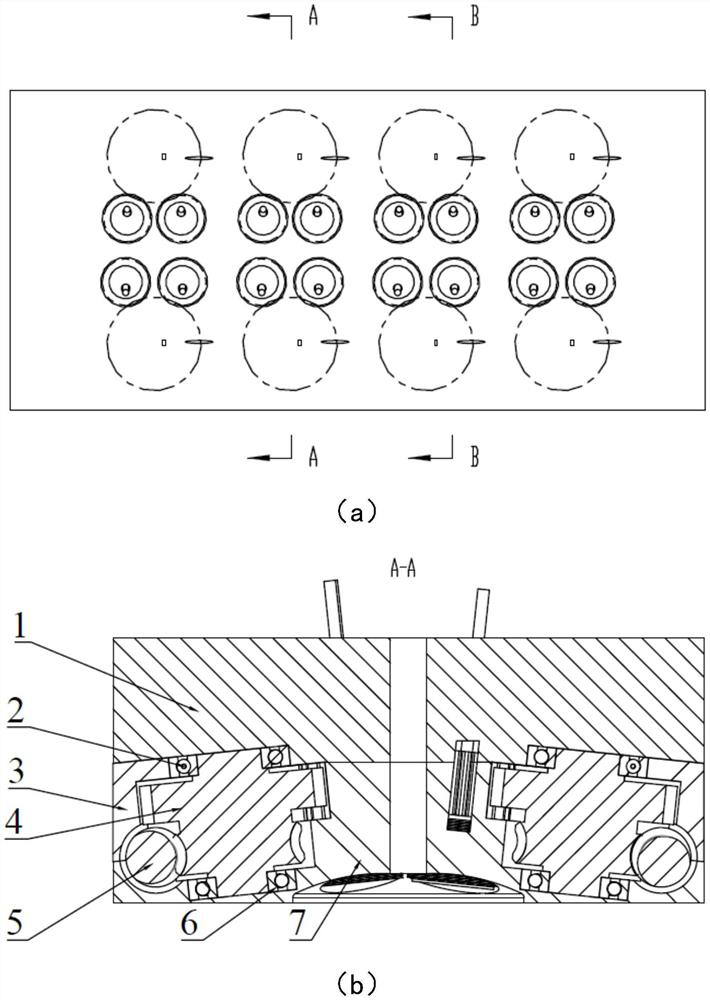

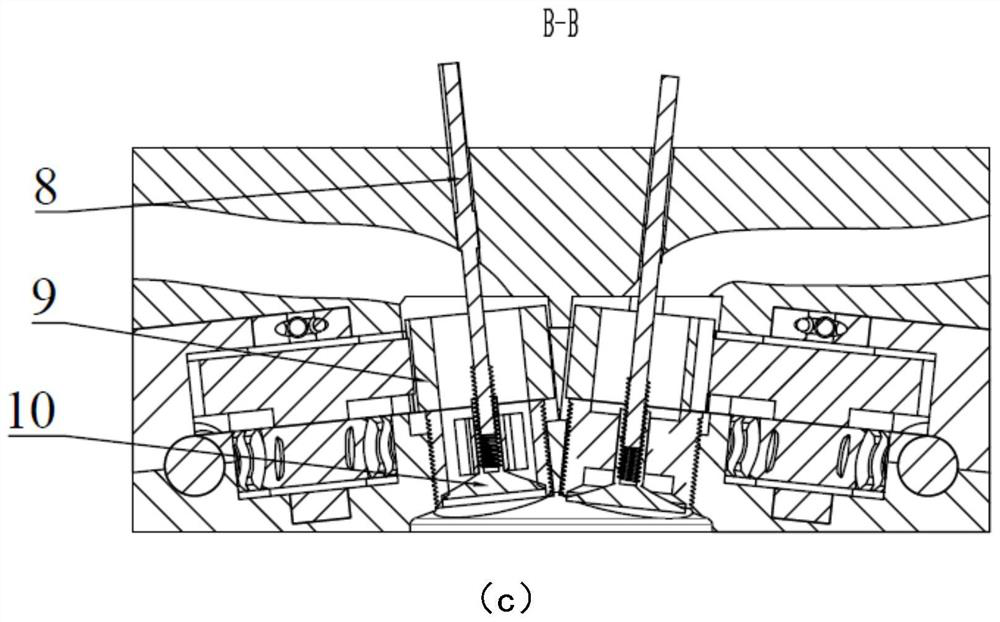

[0021] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. As a part of this specification, the principles of the present invention will be illustrated by examples. Other aspects, features and advantages of the present invention will become apparent from the detailed description. In the figures to which reference is made, the same reference numerals are used for the same or similar parts in different figures.

[0022] An internal combustion engine is a machine that converts the chemical energy of fuel into mechanical energy output. A gasoline engine consists of a body group, a crank connecting rod mechanism, a valve train, an ignition system, a cooling system, a lubrication system and a starting system. When the piston moves to the top dead center, the space formed by the top surface of the piston and the wall surface of the cylinder head is the combustion chamber. In the compression stroke, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com