Reactive dye wet short steaming clean pad dyeing process for cotton/chinlon/lyocell fabric

A reactive dye, wet short steaming technology, applied in the field of textile dyeing and finishing, can solve the problems of chromatic aberration, energy consumption, unfavorable dyeing and color fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

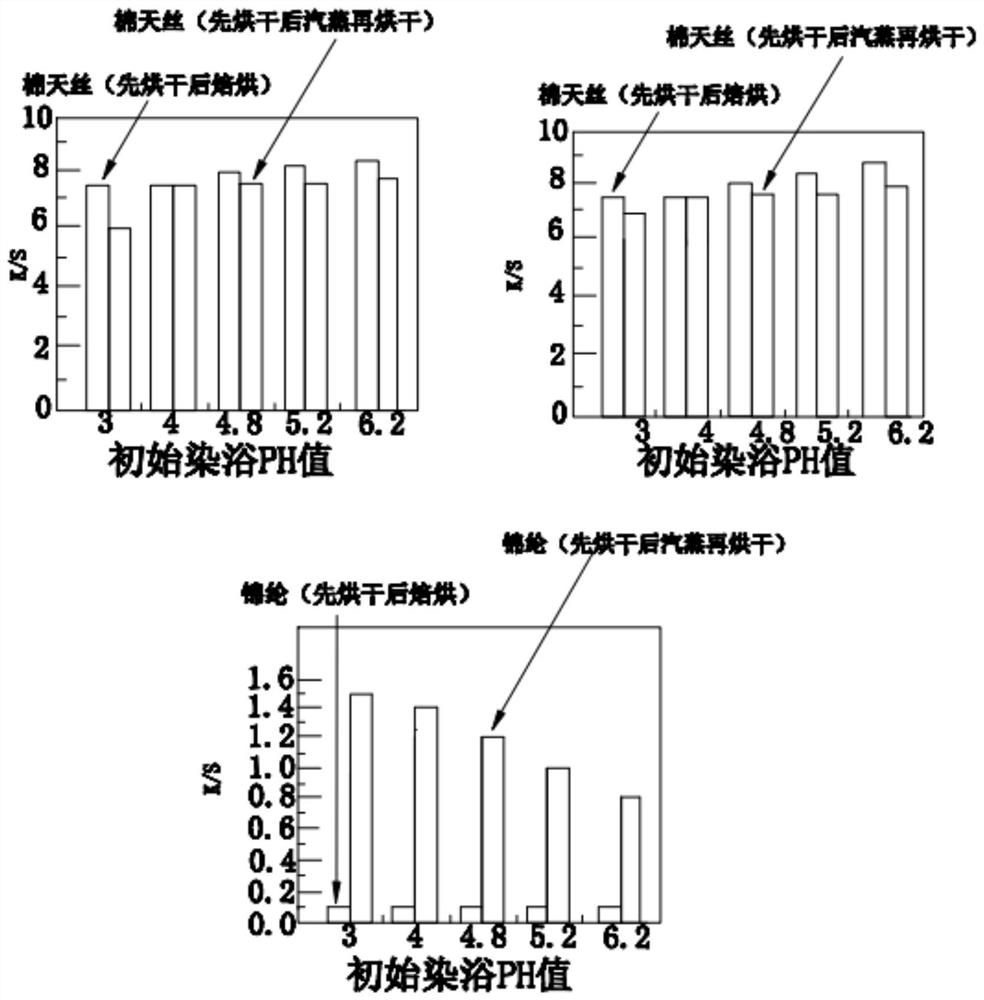

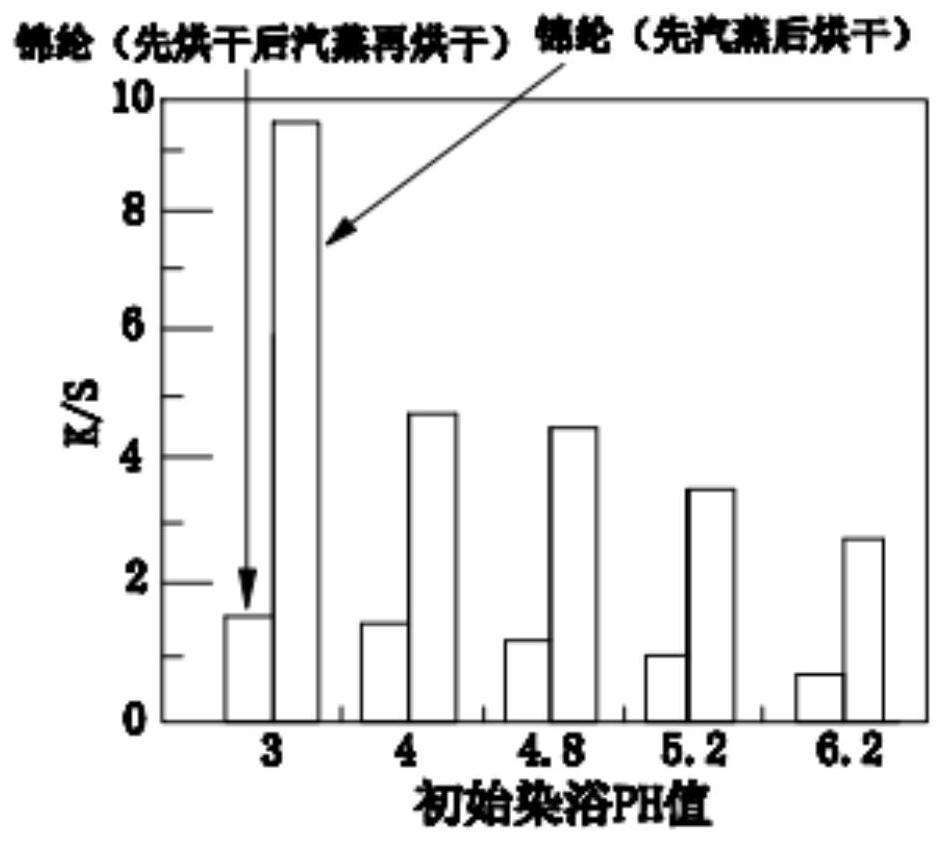

[0046] Cotton / polyamide / lyocell fabric reactive dyes wet short steam cleaning pad dyeing process, including the following steps:

[0047] (1), adopt reactive dyestuff to prepare dye liquor, adjust the pH value of dye liquor to be acidic;

[0048] (2), dipping and pad dyeing solution: two dipping and two rolling, the residual rate is 71%;

[0049] (3), steaming;

[0050] (4), padding alkaline fixing solution: two dips and two rollings, the rolling surplus rate is 20%;

[0051] (5), steaming;

[0052] (6), wash with cold water;

[0053] (7), hot water wash;

[0054] (8), soaping;

[0055] (9), hot water wash;

[0056] (10), wash in cold water;

[0057] (11), drying.

[0058] In the above-mentioned cotton / polyamide / lyocell fabric reactive dye wet short steam cleaning pad dyeing dyeing process, in the step (1), the dye liquor is 5g / L reactive dye.

[0059] The above-mentioned cotton / polyamide / lyocell fabric reactive dye wet short steam cleaning pad dyeing dyeing process is ...

Embodiment 2

[0067] The same parts of this embodiment and embodiment 1 will not be repeated, and the difference is: the cotton / nylon / lyocell fabric reactive dye wet short steam cleaning pad dyeing dyeing process, including the following steps:

[0068] (1), adopt reactive dyestuff to prepare dye liquor, adjust the pH value of dye liquor to be acidic;

[0069] (2), pad dyeing solution: two dips and two rollings, the residual rate is 82%;

[0070] (3), steaming;

[0071] (4), padding alkaline fixing solution: two dips and two rollings, the rolling residual rate is 25%;

[0072] (5), steaming;

[0073] (6), wash with cold water;

[0074] (7), hot water wash;

[0075] (8), soaping;

[0076] (9), hot water wash;

[0077] (10), wash in cold water;

[0078] (11), drying.

[0079] In the above-mentioned cotton / polyamide / lyocell fabric reactive dye wet short steam cleaning pad dyeing dyeing process, in the step (1), the dye liquor is 5-25g / L reactive dye.

[0080] The above-mentioned cotto...

Embodiment 3

[0088] The same parts of this embodiment and embodiment 1 will not be repeated, and the difference is: the cotton / nylon / lyocell fabric reactive dye wet short steam cleaning pad dyeing dyeing process, including the following steps:

[0089] (1), adopt reactive dyestuff to prepare dye liquor, adjust the pH value of dye liquor to be acidic;

[0090] (2), dipping and pad dyeing solution: two dips and two rollings, the residual ratio is 93%;

[0091] (3), steaming;

[0092] (4), Padding Alkaline Color-fixing Solution: Two dipping and two rolling, the residual rate is 28%;

[0093] (5), steaming;

[0094] (6), wash with cold water;

[0095] (7), hot water wash;

[0096] (8), soaping;

[0097] (9), hot water wash;

[0098] (10), wash in cold water;

[0099] (11), drying.

[0100] In the above-mentioned cotton / polyamide / lyocell fabric reactive dye wet short steam cleaning pad dyeing dyeing process, in the step (1), the dye liquor is 25g / L reactive dye.

[0101] The above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com