Reverse suction device of a fiber rotary disc filter

A fiber turntable and anti-suction technology, which is used in mobile filter element filters, filtration and separation, chemical instruments and methods, etc., can solve the problems of short service life of filter cloth, high energy consumption, frequent suction, etc. The effect of prolonging life, low water and energy consumption, and long filtration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with the best embodiment.

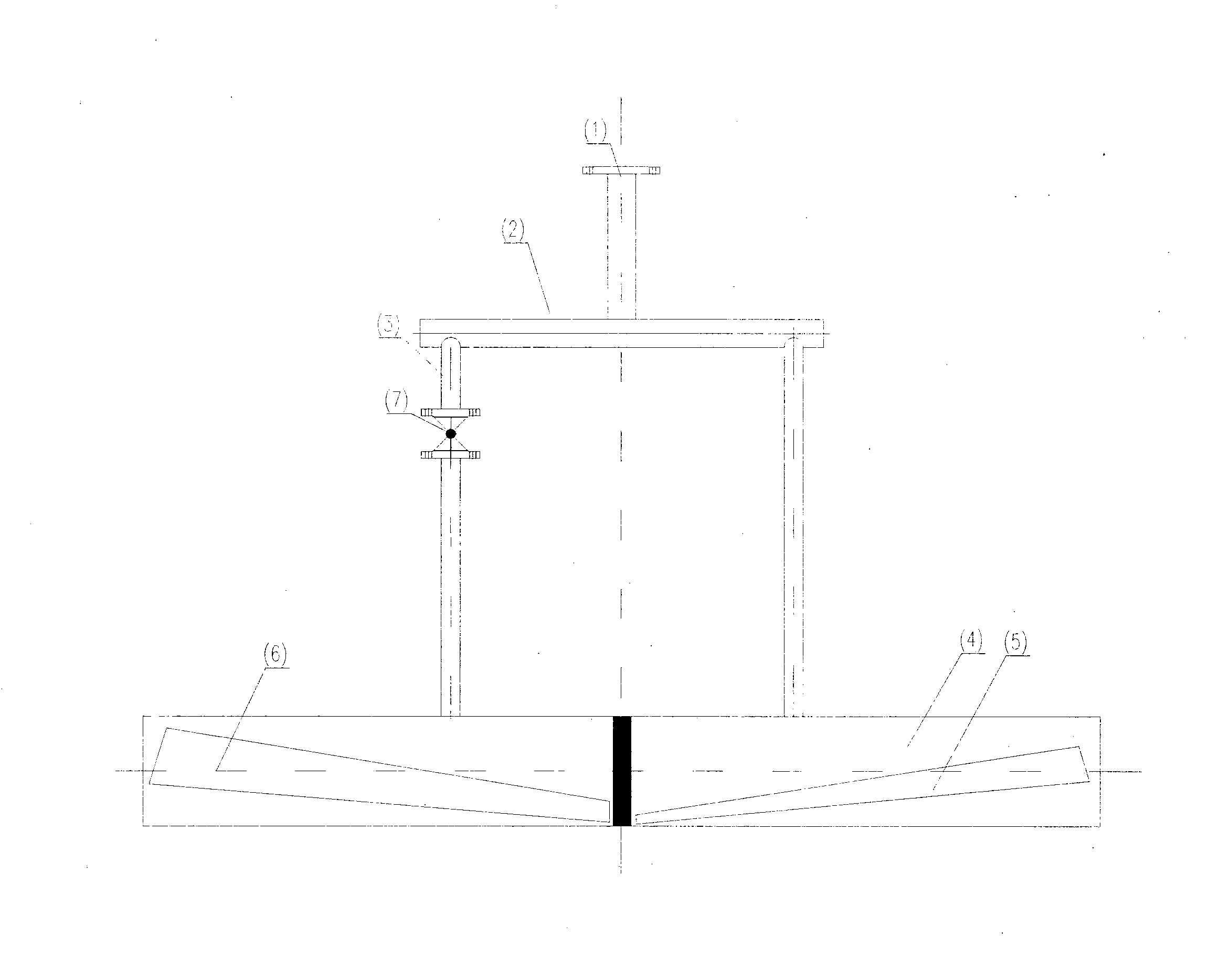

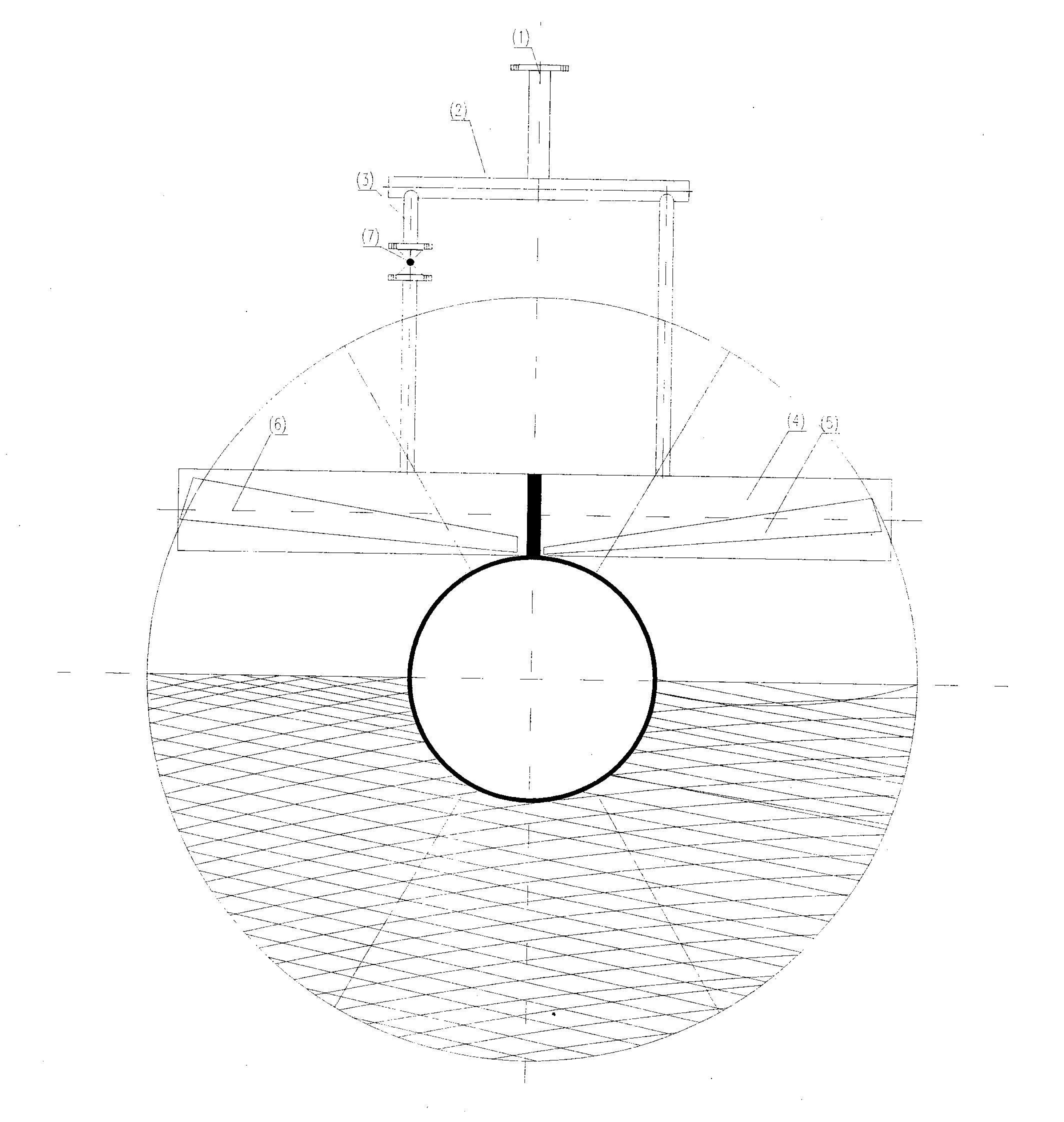

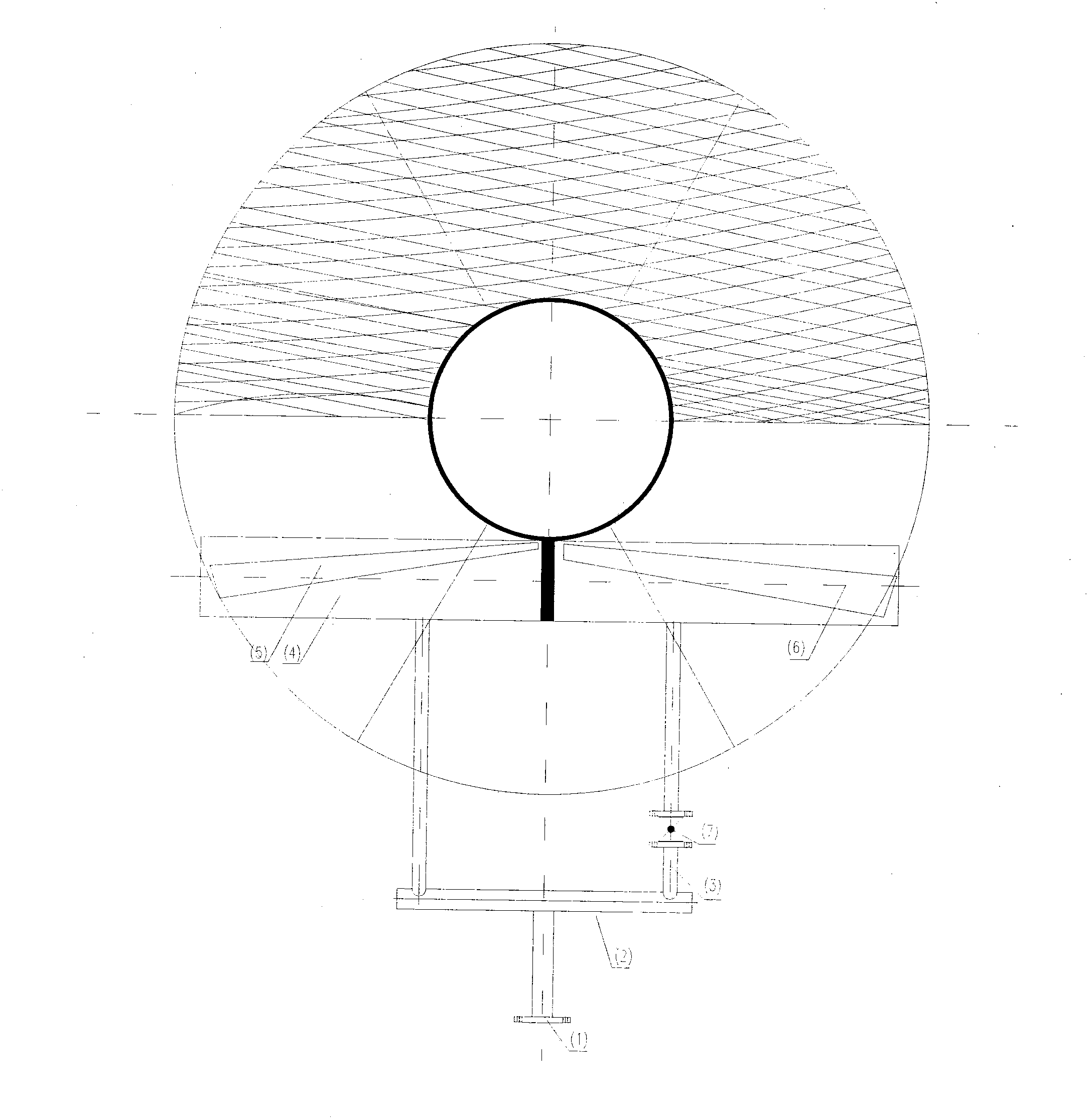

[0012] Such as figure 1 The reverse suction device of the fiber rotary disc filter shown includes an outlet (1), a main pipe (2), a branch pipe (3), a reverse suction disk surface (4), a loose filter cloth tank (5), and a sewage suction tank ( 6) and regulating valve (7); the outlet (1) flange of the anti-suction device is connected to the inlet valve of the anti-suction water pump; Loosen the filter cloth tank body (5) and suction tank body (6), the area of the tank body near the two ends of the disk surface is the largest, and the area near the center of the disk surface is the smallest; the branch pipe (3) is provided with an adjusting valve (7) to adjust the loosening The flow rate of the filter cloth tank body (5) and the dirt suction tank body (6) reaches the intensity of adjusting loose fiber filter cloth and dirt suction.

[0013] The anti-suction device of the fiber turntabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com