Disk type test tube cleaning equipment

A technology for cleaning equipment and test tubes, applied in the field of cleaning equipment and test tube cleaning, can solve the problems of poor functional integration, cumbersome test tube installation and fixing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

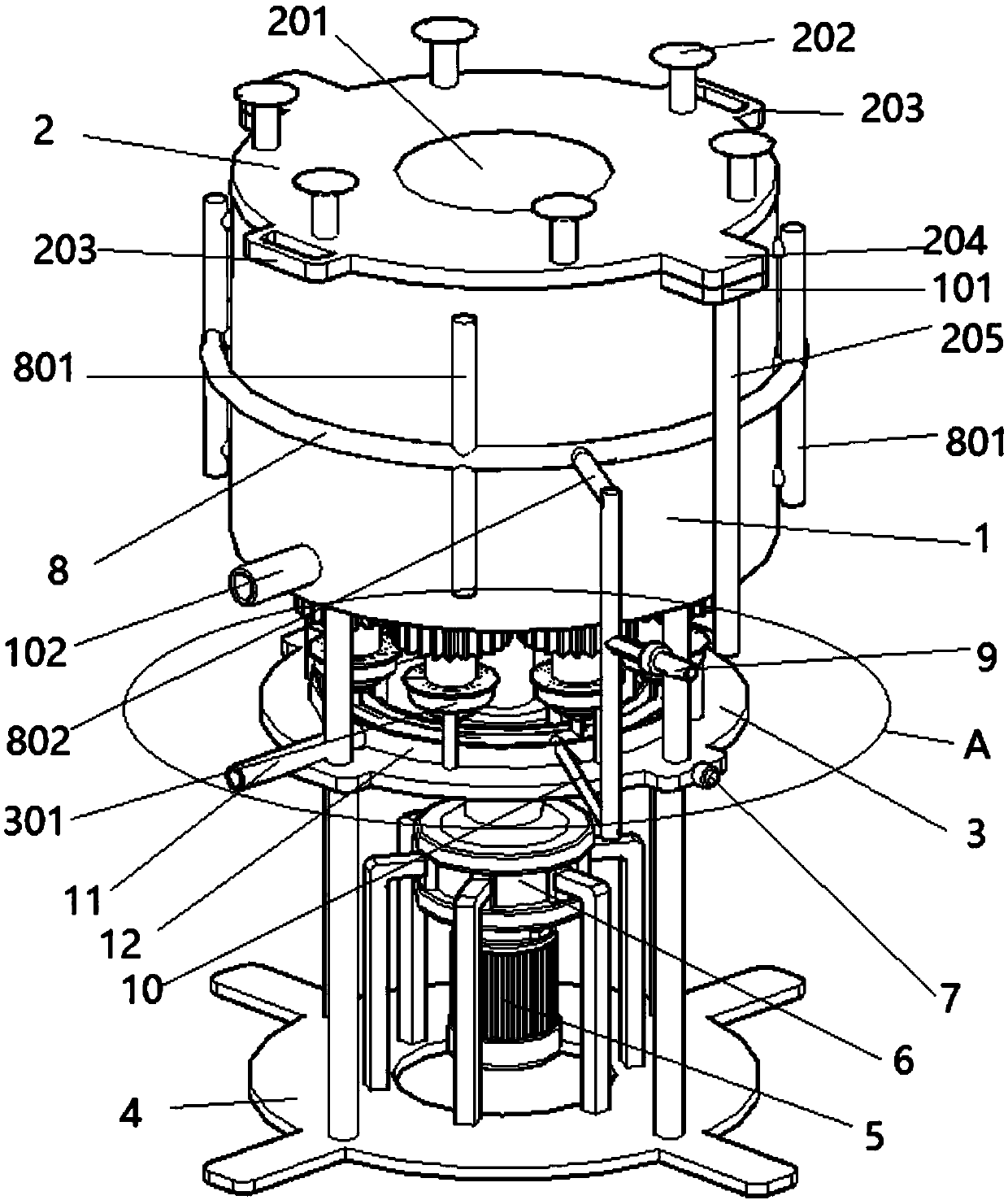

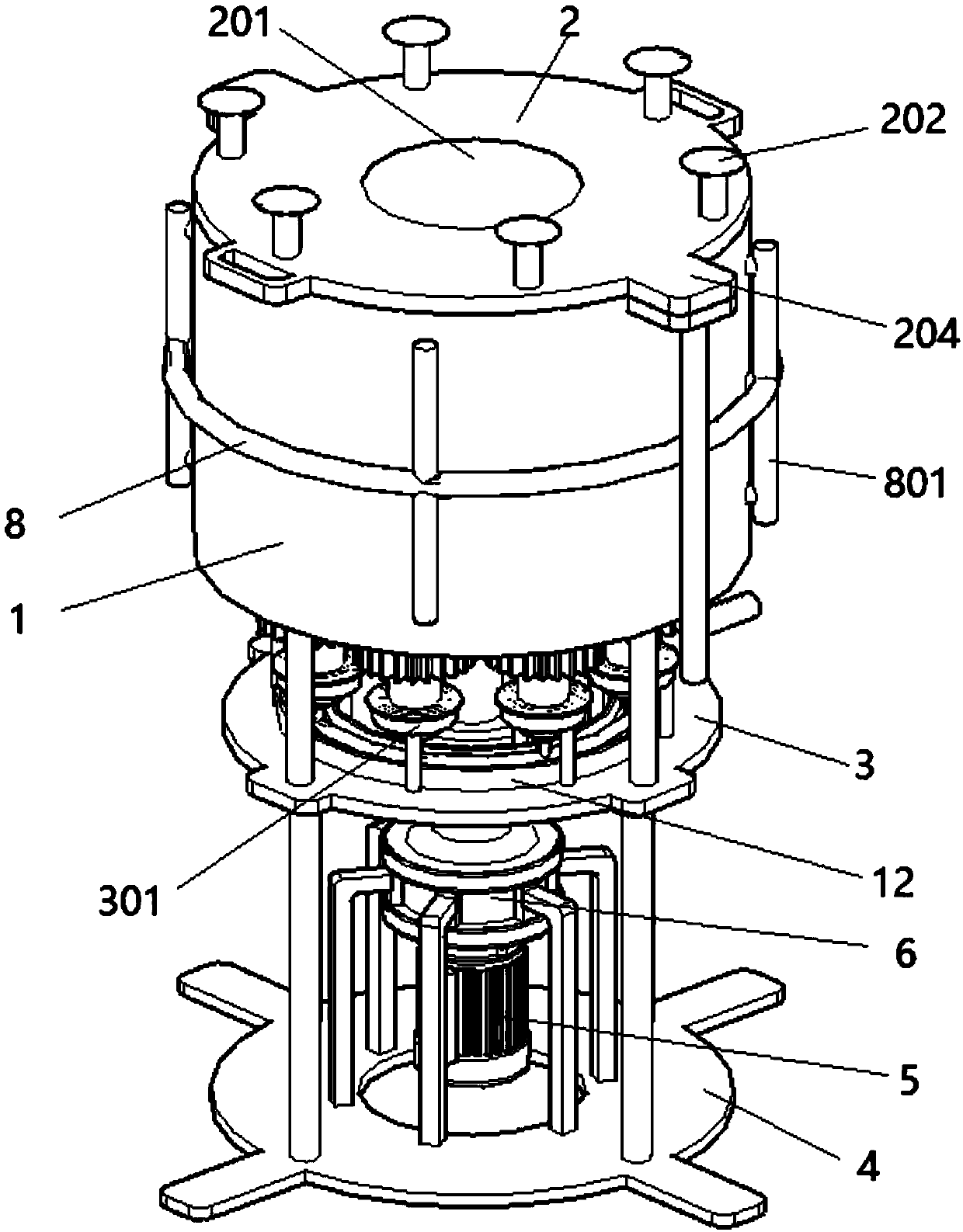

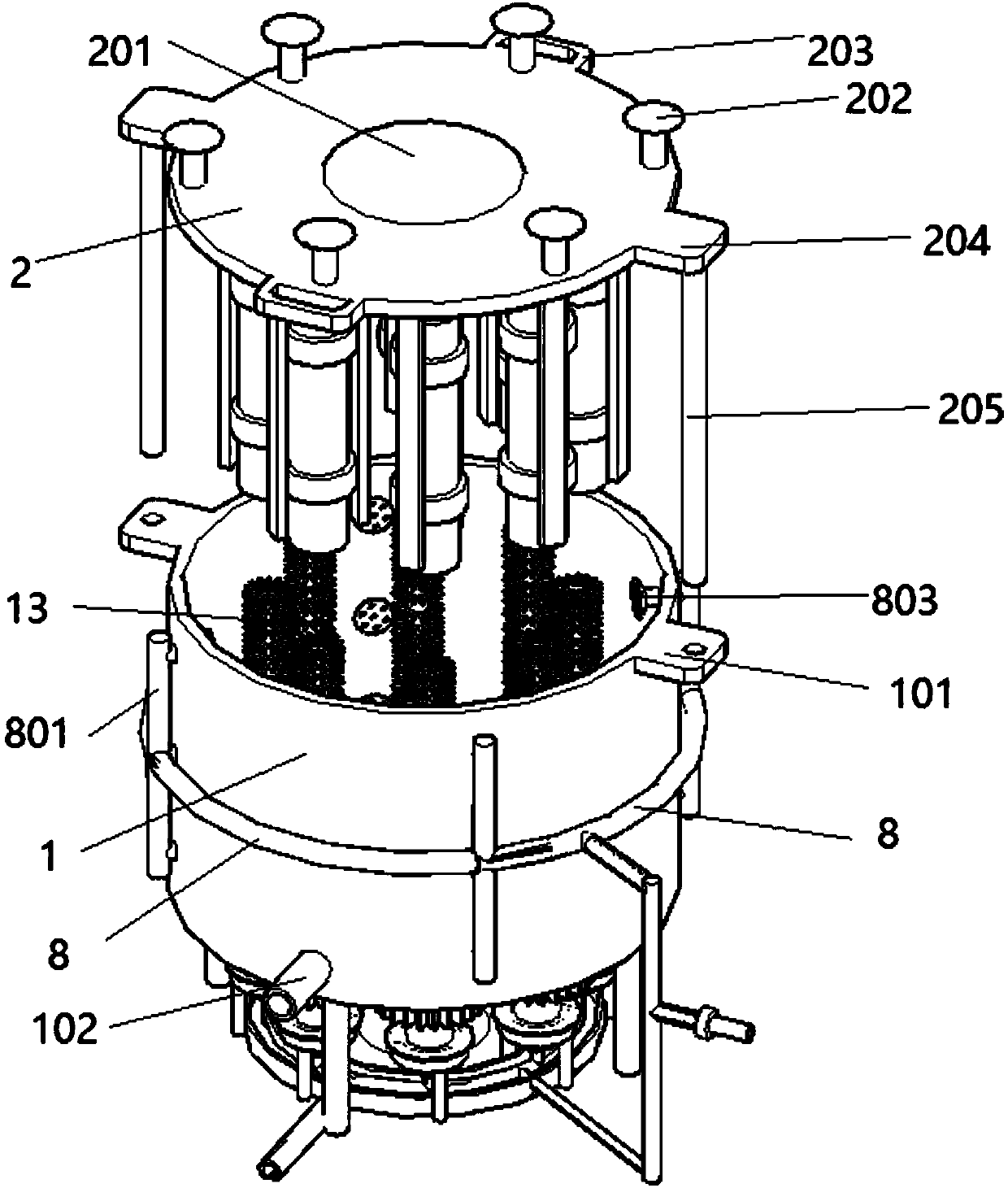

[0043] as attached figure 1 to attach Figure 11 Shown:

[0044] The present invention provides a disc-type test tube cleaning device, which includes a cleaning cylinder 1, a positioning side plate 101, a cleaning cylinder outlet pipe 102, an upper cover 2, a glass window 201, a support seat 202, a handle 203, a positioning plate 204, a positioning shaft 205, and a test tube Fixed ring 206, rubber ring 207, sealing ring 208, support circular plate 3, bearing support seat 301, base plate 4, motor 5, reducer 6, push switch 7, annular water guide pipe 8, vertical water guide pipe 801, first water inlet pipe 802, nozzle 803, water inlet main pipe 9, second water inlet pipe 10, annular water tank outlet pipe 11, annular water tank 12, water spray pipe 121, rotating shaft 13, driven gear 14, driving gear 15 and test tube 16, the cleaning The support top of the cylinder 1 is placed directly above the support circular plate 3, and six vertical aqueducts 801 are arranged in an annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com