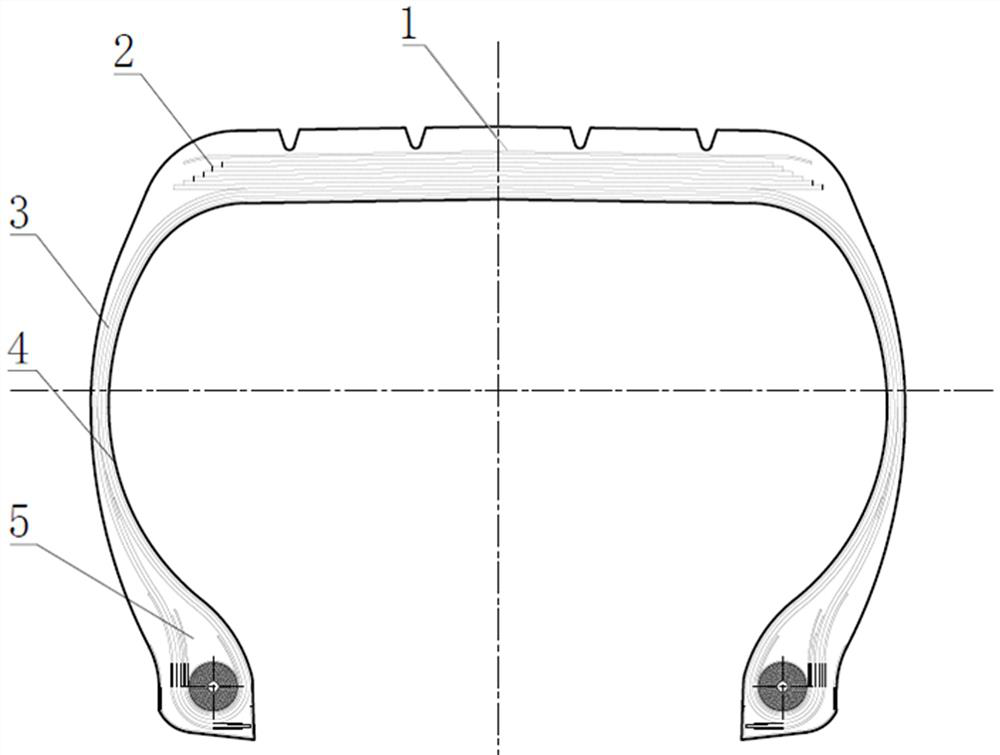

Aviation radial tire belted layer protective layer hanging rubber and preparation method thereof

A radial tire and belt layer technology is applied in the field of rubber and its preparation for the belt layer protective layer of an aviation radial tire. The effect of safety performance, excellent comprehensive performance and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0032] Table 1 Consumption of each raw material in Examples 1-4

[0033]

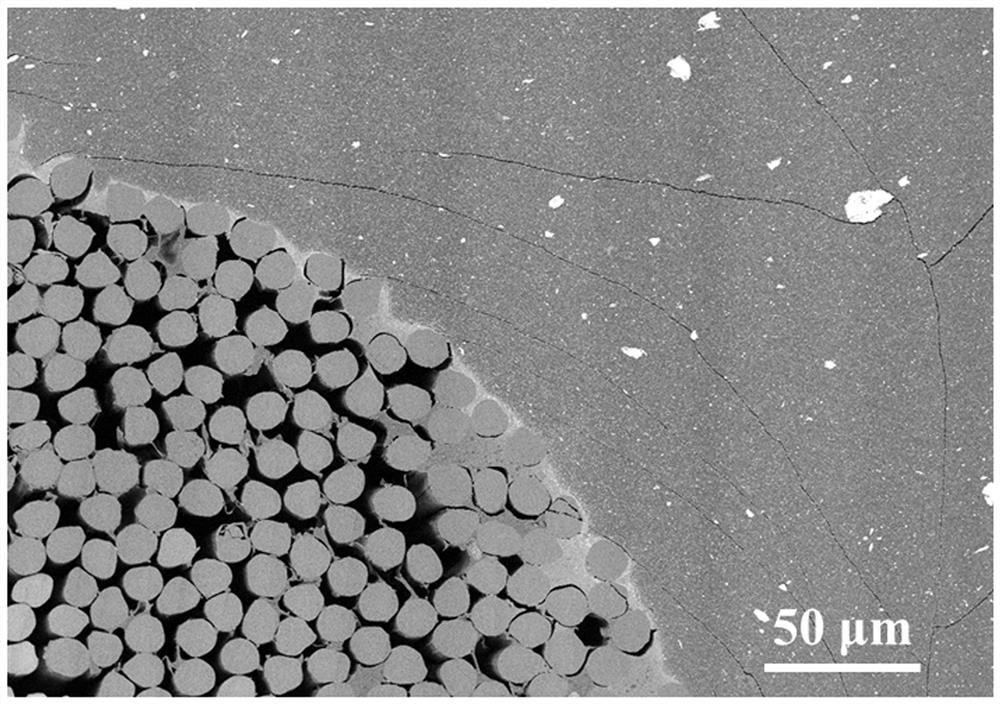

[0034] In the above-mentioned embodiment, domestic high-end natural rubber and styrene-butadiene rubber are used in combination as the raw rubber system. Natural rubber and styrene-butadiene rubber are non-polar unsaturated rubbers, and the vulcanization characteristics of the two are similar, and the same vulcanization system can be used for vulcanization. Natural rubber has the characteristics of producing tensile crystallization in the process of repeated impact and large deformation fatigue, and has good comprehensive performance. Domestic high-end natural rubber has more advantages than imported natural rubber in terms of quality stability and supply stability. SBR has excellent adhesion, processability and physical and mechanical properties, which is conducive to the mutual bonding between the molecular chains of pyridine-butadiene latex rubber in the surface dipping layer of aramid fiber cords...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com