An integrally reinforced unidirectional fiber-reinforced composite lattice sandwich panel and its preparation method

A technology for reinforcing composite materials and unidirectional fibers, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve problems such as low shear strength, avoid local damage, high shear specific strength and specific stiffness , The effect of improving the shear strength of the dough core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

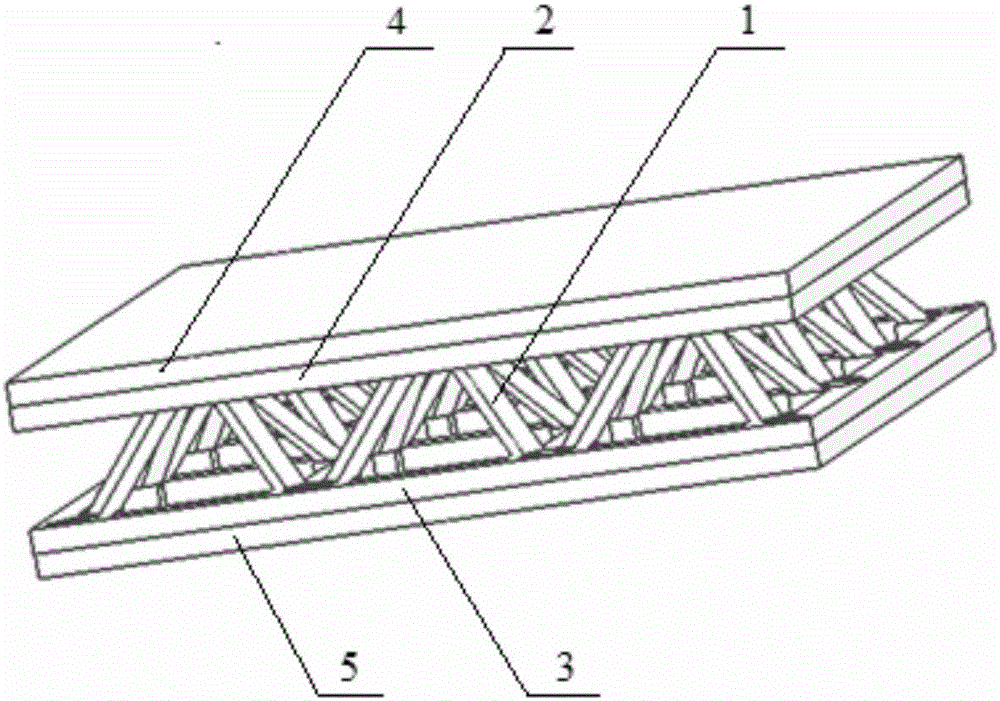

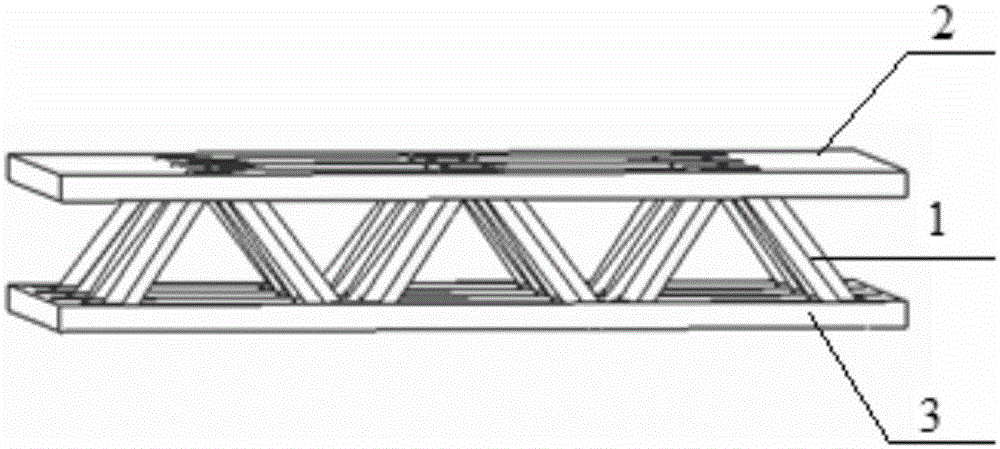

[0032] Embodiment 1: An integrally reinforced unidirectional fiber-reinforced composite material lattice sandwich panel in this embodiment is composed of a pyramidal lattice core 1, a reinforced upper panel 2, a reinforced lower panel 3, and a composite material lower panel 5 ;

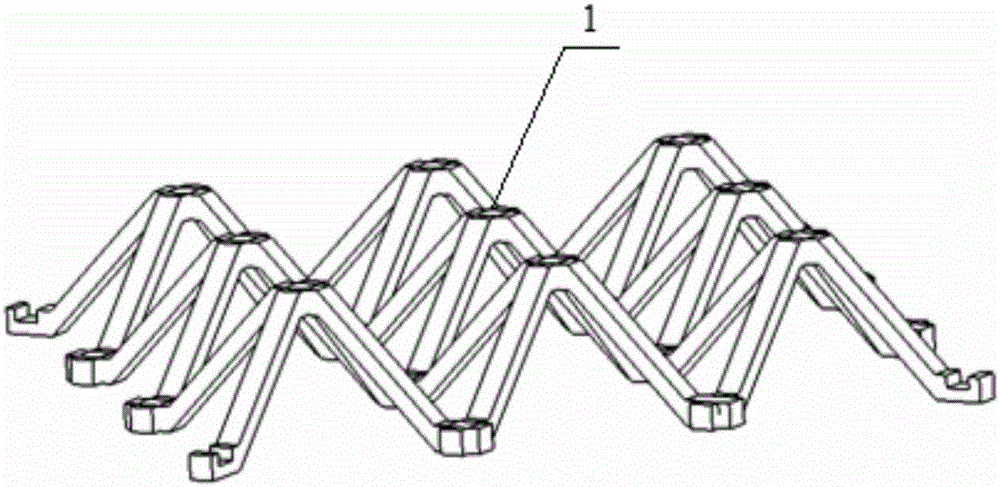

[0033] The pyramid lattice core 1 is composed of a plurality of unidirectional fiber-reinforced composite material lattice structure unit cells 6, and each unidirectional fiber-reinforced composite material lattice structure unit cell 6 is composed of four rods with a pyramid structure. In the horizontal direction, interlocking notches are provided at the joints of the vertical rods, and multiple unidirectional fiber-reinforced composite lattice structure unit cells 6 interlock with each other in a criss-cross manner through the interlocking notches to form a pyramid. Dot matrix core 1;

[0034] All two unidirectional fiber-reinforced composite lattice structural unit cells 6 at the upper end of the ...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment differs from Embodiment 1 in that: the materials of the reinforced upper panel 2 and the reinforced lower panel 3 are metal materials or composite materials. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment differs from Embodiment 2 in that: the reinforced upper panel 2 and the reinforced lower panel 3 are made of low-density magnesium alloy or aluminum alloy. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com