High ground stress soft rock tunnel supporting structure system and construction method thereof

A high ground stress and support structure technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of easy damage to the secondary lining structure, damage to the support structure, failure of anchor rods, etc., to simplify the construction process and improve the bearing capacity capacity, high load-carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

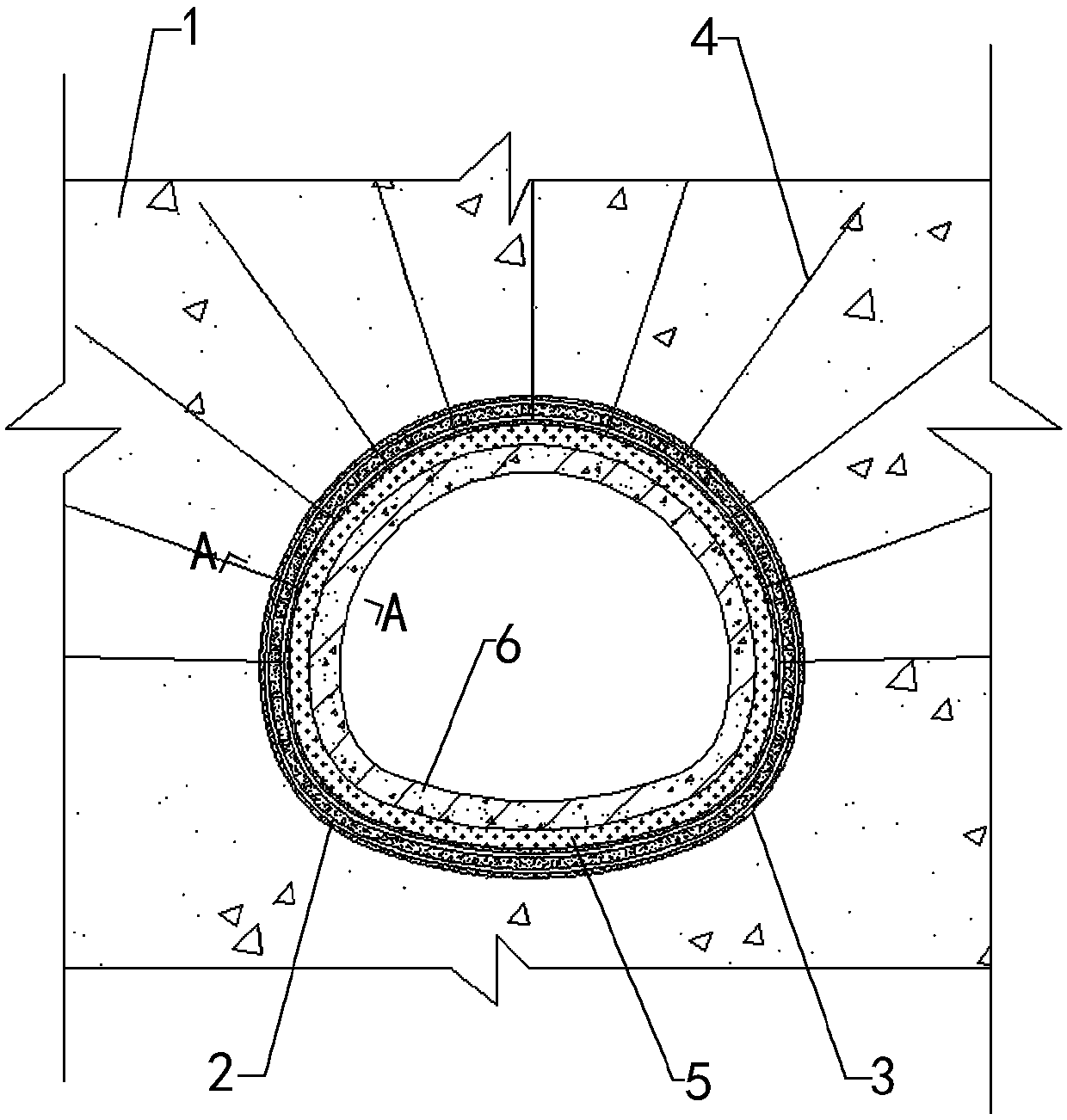

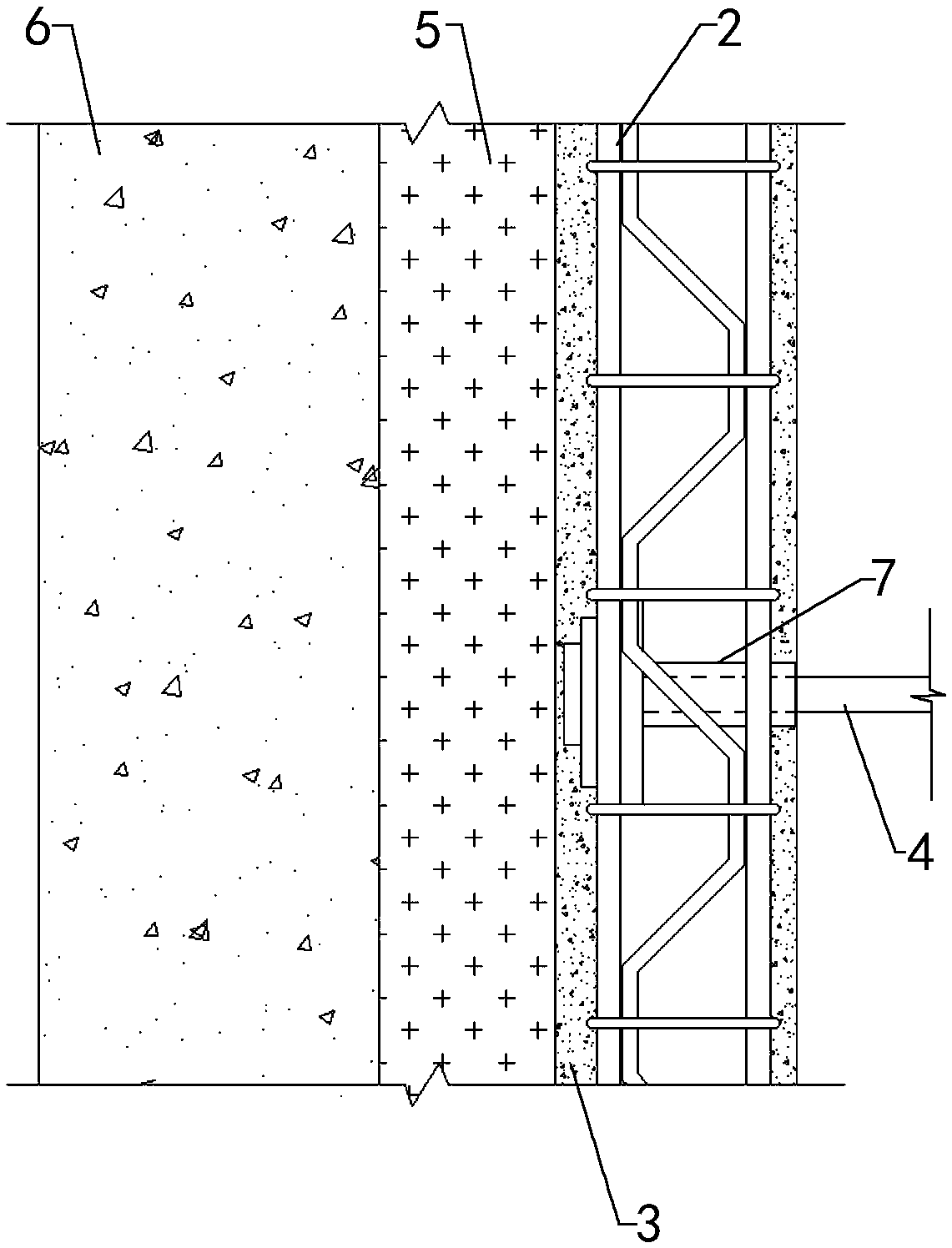

[0051] like Figure 1 to Figure 5 As shown, the high ground stress soft rock tunnel support structure system of the present invention includes the initial pressure yield support, pressure energy storage layer 5 and permanent support structure 6. The steel frame 2 and the shotcrete 3, the outer side of the grid steel frame 2 close to the tunnel surrounding rock 1 is provided with a yield anchor 4; the two sides of the yield energy storage layer 5 are respectively close to the inner side of the yield initial support and the permanent support The outer side of the structure 6 is provided.

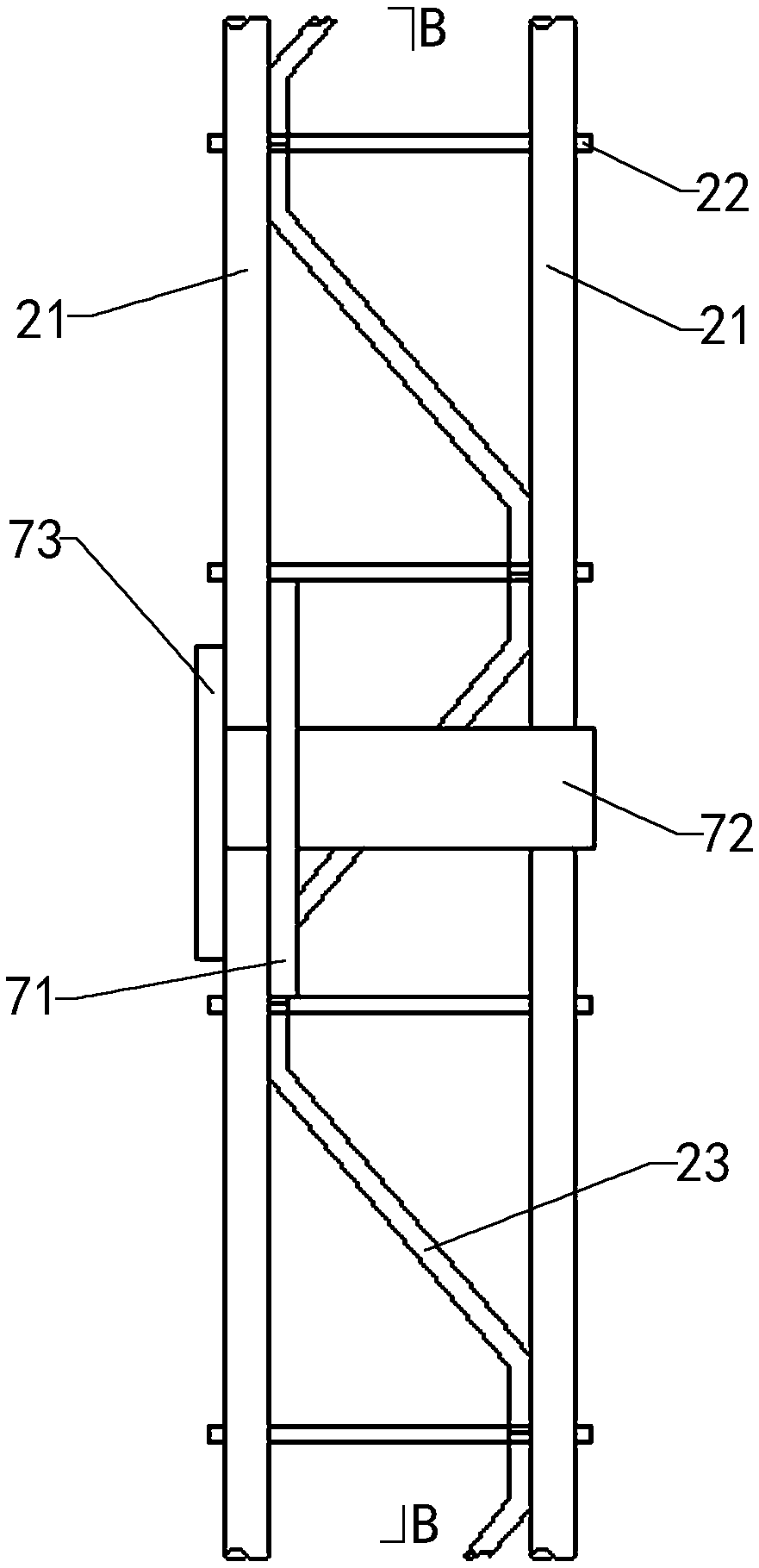

[0052]The thickness of the initial support under pressure is 25-40cm. The grid steel frame 2 is formed by a plurality of single steel frames attached to the tunnel surrounding rock 1 and arranged side by side along the tunnel circumference. The spacing is 0.5-1.5m. The single steel frame is a truss structure with a rectangular longitudinal section. The height of the longitudinal section is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com