Composite lining structure of high-pressure diversion tunnel

A water diversion tunnel and composite lining technology, applied in the field of tunnel engineering, can solve the problems of ignoring the load bearing effect of the support layer and the waste of hydraulic tunnel construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure and features of the present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that various modifications can be made to the embodiments disclosed herein, therefore, the embodiments disclosed in the specification should not be regarded as limitations of the present invention, but only as examples of embodiments, the purpose of which is to make the present invention The features of the invention are obvious.

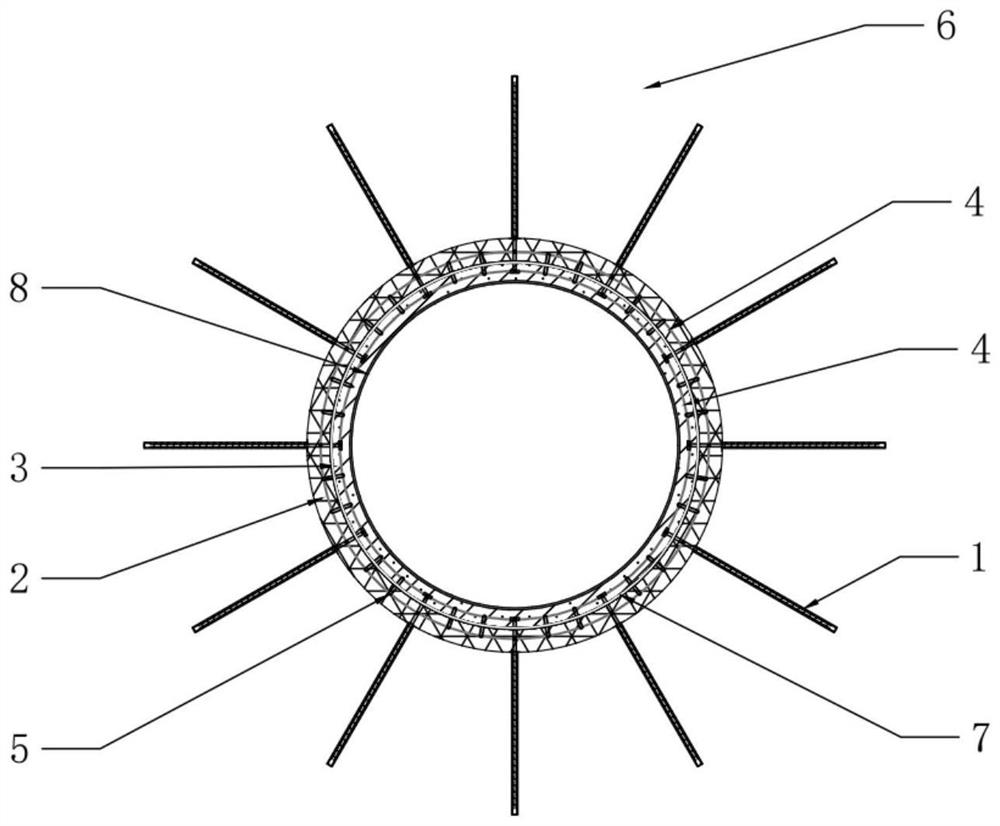

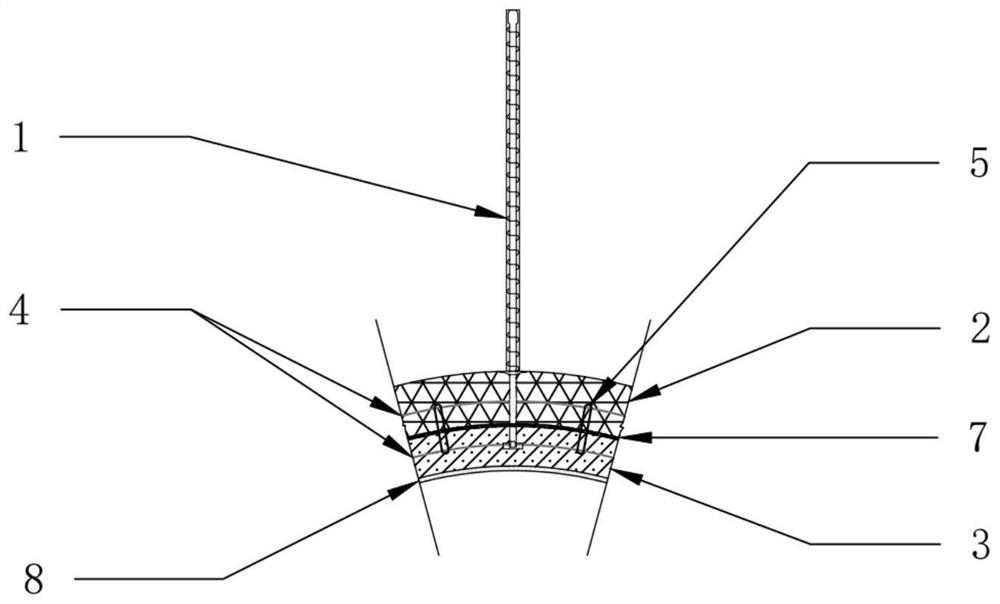

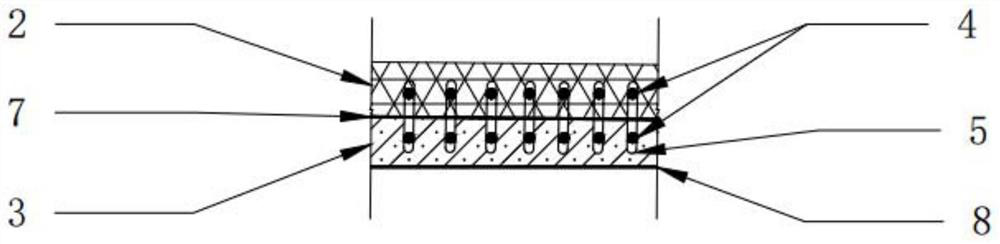

[0025] like Figure 1-Figure 3 As shown, the novel high-pressure water diversion tunnel composite lining structure disclosed in the present invention includes an anchor rod 1 , a supporting layer 2 , a lining layer 3 , a carbon fiber reinforcement 4 and a connecting reinforcement 5 .

[0026] The bolt 1 is driven into the surrounding rock 6 around the tunnel, and its function is to strengthen and protect the surrounding rock and improve the bearing capacity and self-supporting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com