Toughening modified epoxy curing agent for dry-type transformer and preparation method of toughening modified epoxy curing agent

An epoxy curing agent, dry-type transformer technology, applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc. problems, to achieve the effect of high controllability of the production process and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

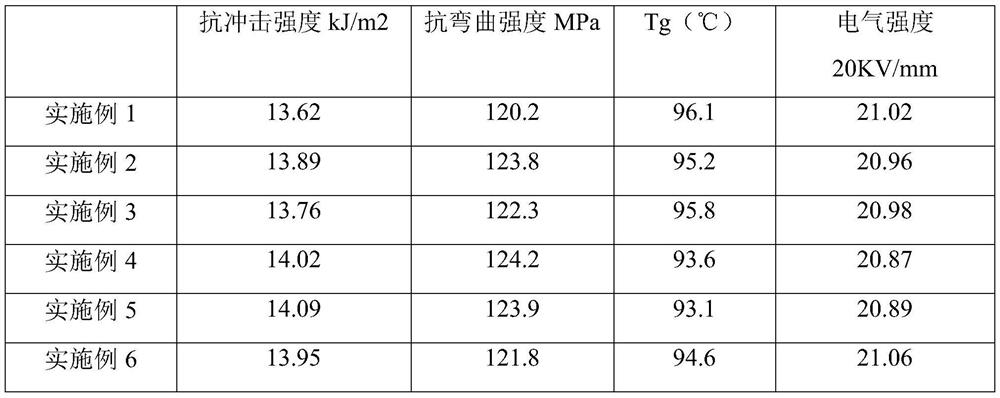

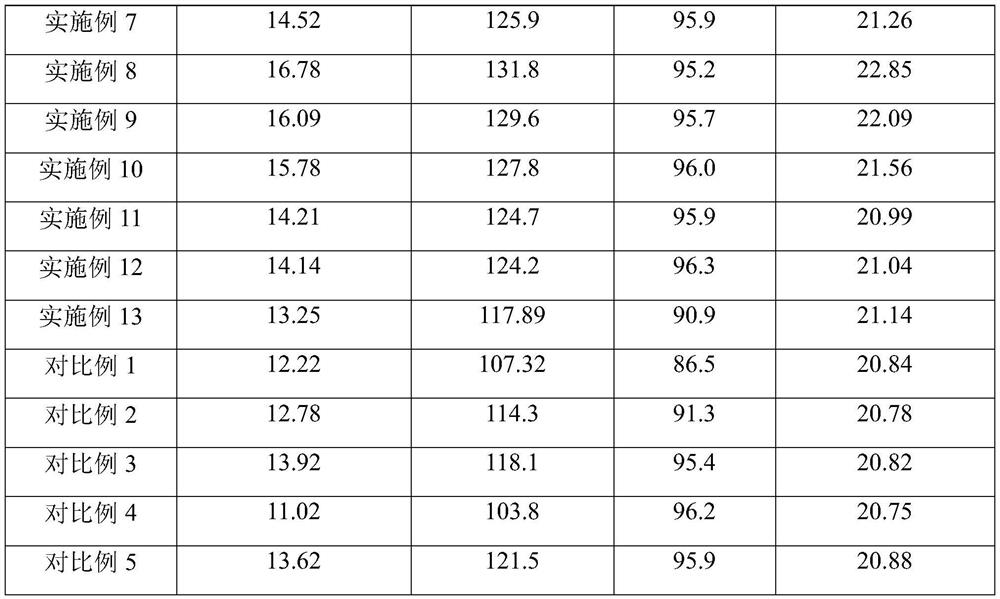

Examples

preparation example 1

[0040] The preparation technology of methyltetrahydrophthalic anhydride, comprises the following steps:

[0041]Step 1, the diene synthesis procedure prepares the crude product of methyltetrahydrophthalic anhydride: piperylene, isoprene, polymerization inhibitor-diquinone, sodium isopropionate (maleic anhydride quality of 0.3%) into the reaction kettle, the temperature in the kettle is raised to 70°C, and the pressure in the kettle is adjusted to 0.2MPa; maleic anhydride is added dropwise to the reaction kettle, and the temperature in the kettle is controlled at 45°C during the dropping process, so that The temperature in the kettle was kept at 90°C for 3 hours; then the pressure in the kettle was reduced to 80kPa, the temperature was raised to 140°C, and the remaining unreacted piperylene, isoprene and polymerization inhibitor were distilled off to obtain a crude product;

[0042] Step 2, isomerization and rectification process to prepare high-purity methyltetrahydrophthalic ...

Embodiment 1

[0045] A toughening modified epoxy curing agent for dry-type transformers disclosed in the present application is prepared from the following raw materials: methyltetrahydrophthalic anhydride, sodium acetate pentahydrate, and a polymer with a weight average molecular weight of 2000. Propylene glycol diglycidyl ether. The molar amount of methyltetrahydrophthalic anhydride is 0.96 times the total molar amount of hydroxyl groups in the polyol. The catalyst is 0.005 times the mass of methyltetrahydrophthalic anhydride.

[0046] The preparation technology of methyltetrahydrophthalic anhydride, comprises the following steps:

[0047] Step 1, the diene synthesis process prepares the crude product of methyltetrahydrophthalic anhydride: put piperylene, isoprene and polymerization inhibitor into the reaction kettle, the temperature in the kettle is raised to 55°C, and the The internal pressure was adjusted to 0.08-0.09MPa; maleic anhydride was added dropwise to the reaction kettle, an...

Embodiment 2

[0055] The difference between Example 2 and Example 1 is: a toughening modified epoxy curing agent for dry-type transformers is prepared from the following raw materials: methyltetrahydrophthalic anhydride, sodium acetate pentahydrate , Polypropylene glycol diglycidyl ether with a weight average molecular weight of 1000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com