Full-automatic electrostatic paper sticking device

A fully automatic and sticky paper technology, which is applied in the field of electrostatic paper sticking device and full-automatic electrostatic sticking device, can solve the problems of excessive slack, excessive tension of paper, low production efficiency, etc., and achieve the effect of reducing the extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

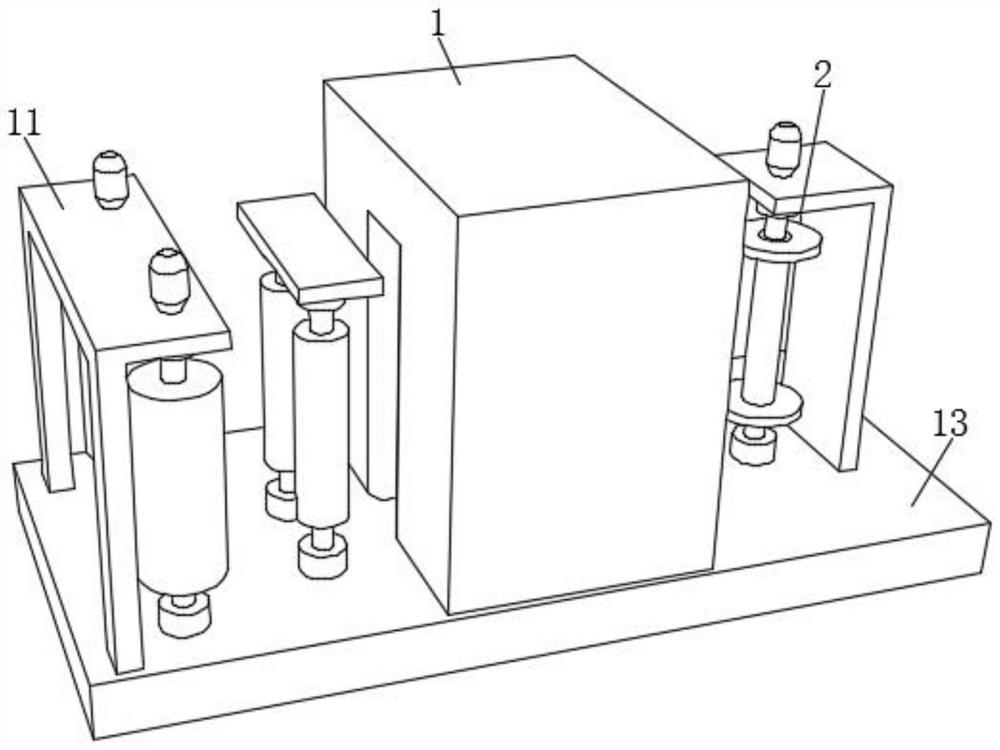

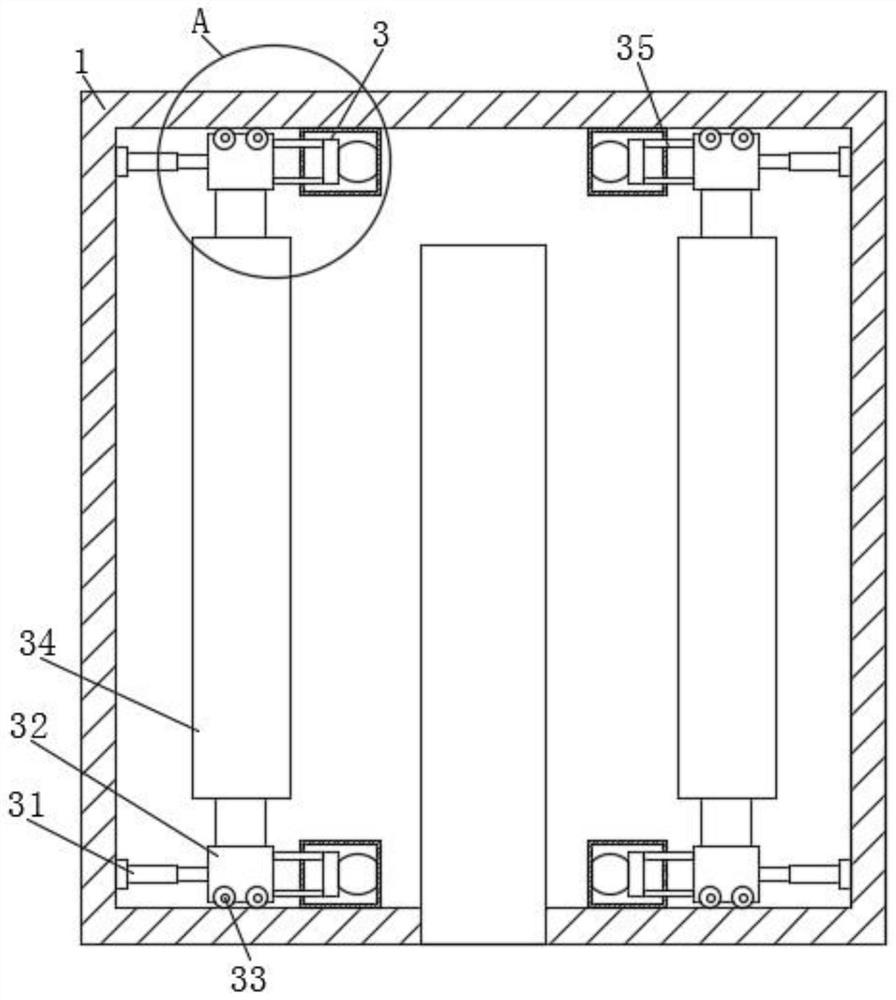

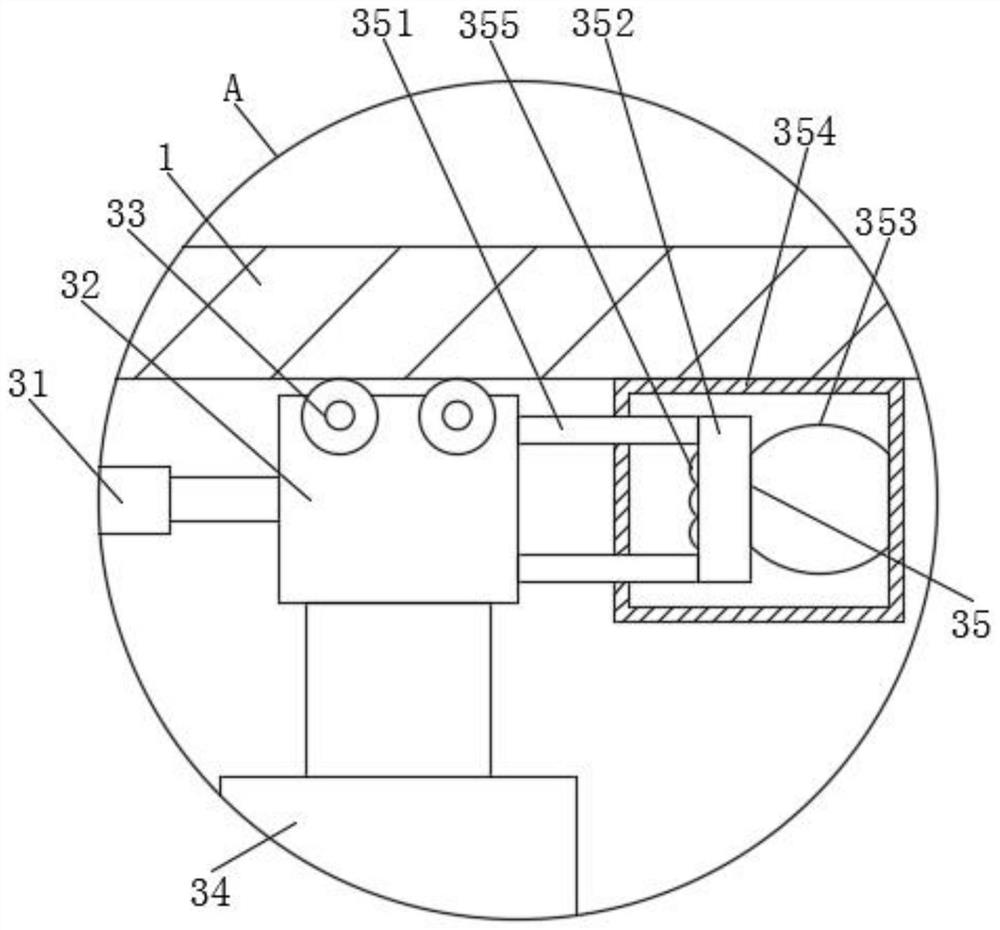

[0031] like Figure 1-6As shown, the present invention provides a fully automatic electrostatic sticking device, including a sticking device main body 1 and a rewinding mechanism 2, the lower surface of the sticking device main body 1 is fixedly connected with a base 13, and the lower surface of the rewinding mechanism 2 is connected to the base 13. The outer surface of the base 13 is fixedly connected, one side of the main body 1 of the paper sticking device is provided with a feeding assembly 11, the outer surface of the main body 1 of the paper sticking device is provided with a discharge opening 12, and the inside of the main body 1 of the paper sticking device 1 is provided with a tension level The self-adjusting mechanism 3 and the cutting mechanism 4, the tensioning degree self-adjusting mechanism 3 includes a telescopic rod 31, and the outer surface of one end of the telescopic rod 31 is fixedly connected to the inner wall of the main body 1 of the paper sticking device...

Embodiment 2

[0034] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the tension adjustment assembly 35 includes a sliding rod 351, and the outer surface of one end of the sliding rod 351 is fixedly connected with the outer surface of the connecting block 32, A sliding sleeve 354 is movably connected on the outer surface of the sliding rod 351, and the outer surface of the sliding sleeve 354 is fixedly connected with the inner wall of the main body 1 of the paper sticking device. The outer surface of the other end of the sliding rod 351 is fixedly connected with a push plate 352. The outer surface of 352 is fixedly connected with a soft protective hemisphere 355, the outer surface of the push plate 352 is fixedly connected with an elastic sleeve plate 353, one side of the elastic sleeve plate 353 is fixedly connected with the inner wall of the sliding sleeve 354, and the elastic sleeve plate 353 A connecting rod 3531 ...

Embodiment 3

[0037] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, one end of the hydraulic push rod 42 is fixedly connected to the inner wall of the cutting groove 41, and one side of the connecting plate 43 is connected to the inner wall of the hydraulic push rod 42. The outer surface of the other end is fixedly connected, one side of the limit rod 44 is fixedly connected to the outer surface of the connecting plate 43, the outer surfaces of the connecting plate 43 and the limit rod 44 are movably connected with the inner wall of the cutting groove 41, and the cutting blade 45 One side of the blade is fixedly connected with the outer surface of the connecting plate 43, the card slot 46 is opened on the inner wall of the discharge port 12, the blade protection component 47 is arranged on the inner side of the card slot 46, the blade protection component 47 includes a movable slot 471, the movable slot 471 is opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com