Machining equipment for prefabricated box girder web steel bar frame

A technology for processing equipment and steel frames, which is applied in the field of processing equipment for prefabricated box girder belly steel frames, can solve the problems of high labor intensity, large labor input, and slow construction progress, etc., and achieve a simple and novel overall structure, ensuring operation safety, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

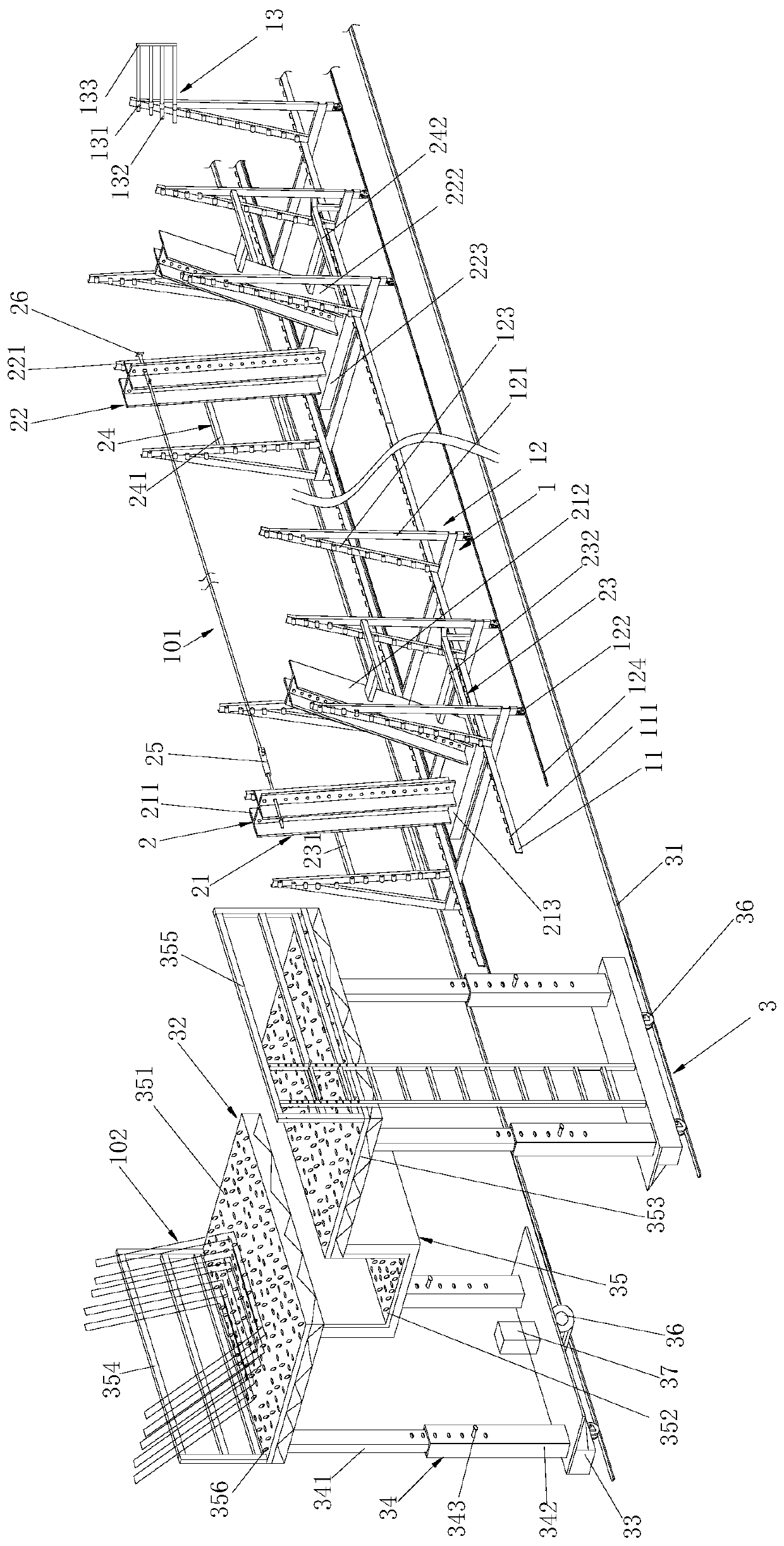

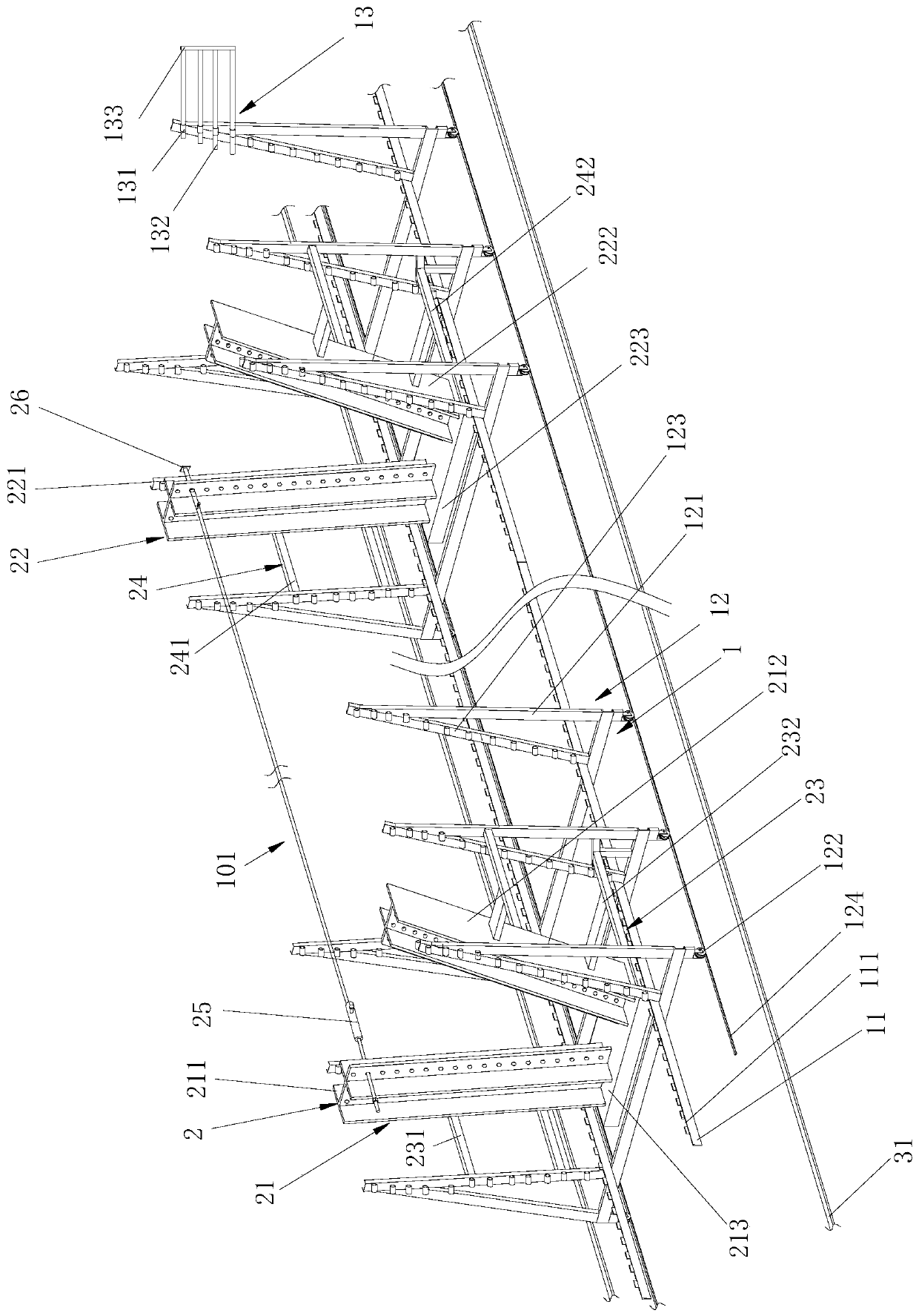

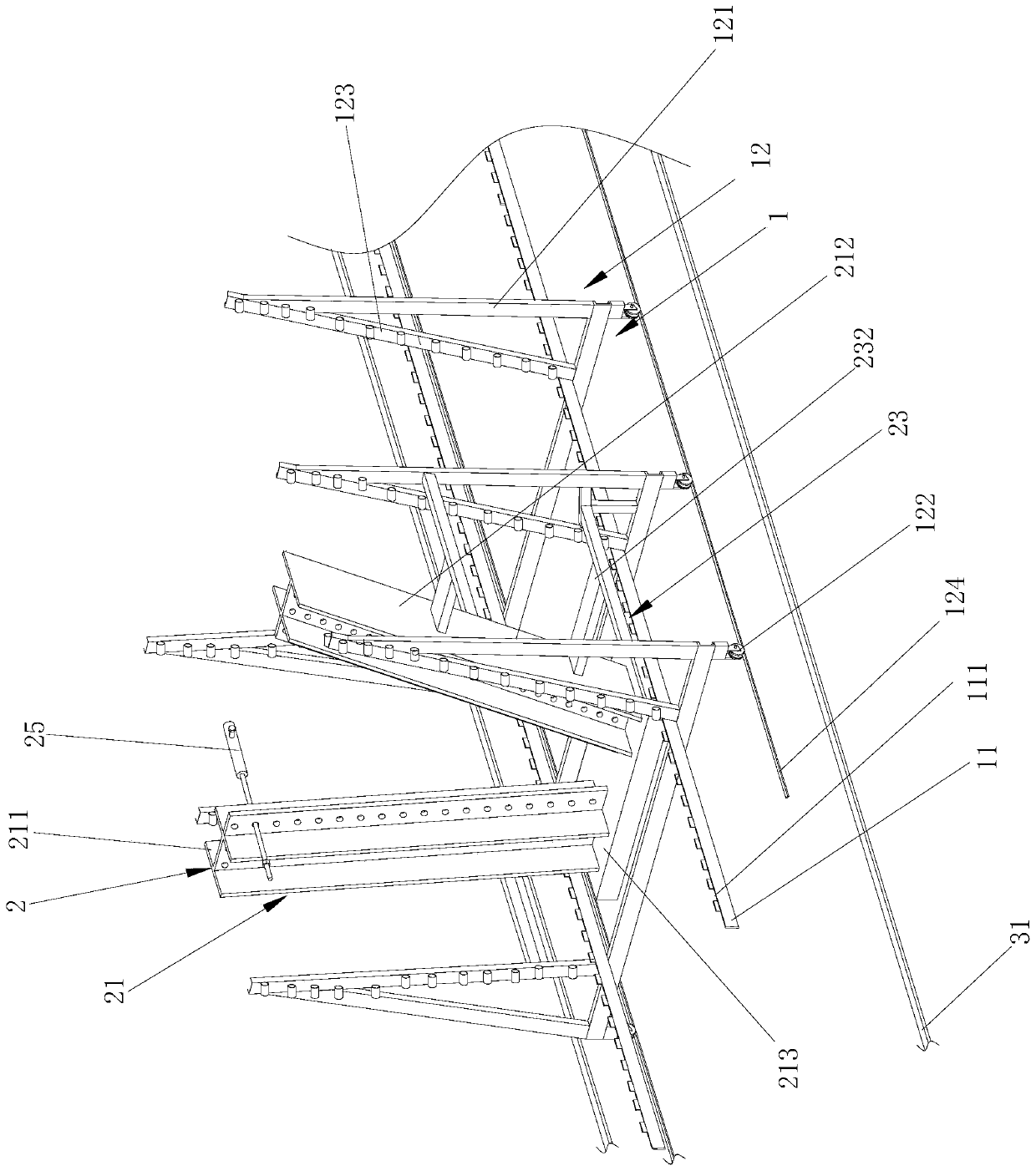

[0043] combine Figure 1 to Figure 7, processing equipment for prefabricated box girder abdominal reinforcement frame, said prefabricated box girder abdominal reinforcement frame includes longitudinal reinforcement 101 and transverse reinforcement frame 102, processing and installation equipment includes external positioning device 1, stretching device 2 and distribution device 3.

[0044] The outer positioning device 1 includes a first longitudinal positioning plate 11 for connecting the transverse reinforcement frame 102 and a plurality of longitudinally arranged first transverse positioning frames 12, and the two first longitudinal positioning plates 11 are arranged parallel to each other on a plurality of first transverse positioning frames. Inside the positioning frame 12 , the first transverse positioning frame 12 is connected with a plurality of first steel bar position adjustment assemblies 13 for positioning the longitudinal steel bars 101 .

[0045] The stretching de...

Embodiment 2

[0069] During the use of the above-mentioned processing equipment for prefabricating the abdominal reinforcement frame of a box girder, the longitudinal reinforcement 101 is installed first, and then the transverse reinforcement frame 102 is installed.

[0070] Before installing the longitudinal reinforcing bars 101 , the spacing distance of the longitudinal reinforcing bars 101 is firstly determined, and the spacing distance at this time is realized by the adjustment of the first reinforcing bar position adjustment assembly 13 . There are multiple sets of first steel bar position adjustment assemblies 13, and multiple sets of first steel bar position adjustment assemblies 13 are connected to the side walls of the first transverse oblique struts 123; the first steel bar position adjustment assemblies 13 include four first adjustment sleeves 131 Each first adjustment sleeve 131 is connected with a first adjustment horizontal sleeve rod 132 , and the ends of the four first adjust...

Embodiment 3

[0073] The cross-section of the transverse reinforcement frame 102 in the present invention is a trapezoidal frame shape, and the transverse reinforcement frame 102 can be adapted to be connected between a plurality of positioned longitudinal reinforcement bars 101. When the transverse reinforcement frame 102 is installed, the multiple transverse reinforcement bars The frame 102 is placed on the left discharge part 351 and the right discharge part 353 of the distribution vehicle, and the discharge worker stands on the middle stand part 352 and places the transverse reinforcement frame 102 between the two first longitudinal positioning plates 11 .

[0074] An installer working between the outer positioning devices 1 installs the transverse reinforcement frame 102 into the first positioning plate notch 111 of the first longitudinal positioning plate 11 . After the horizontal reinforcing bar frame 102 is installed, the worker welds the longitudinal reinforcing bar 101 and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com