Chemical raw material dumping device based on chemical production

A chemical raw material and dumping device technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve problems such as general safety, no flexible control function, and small dumping range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

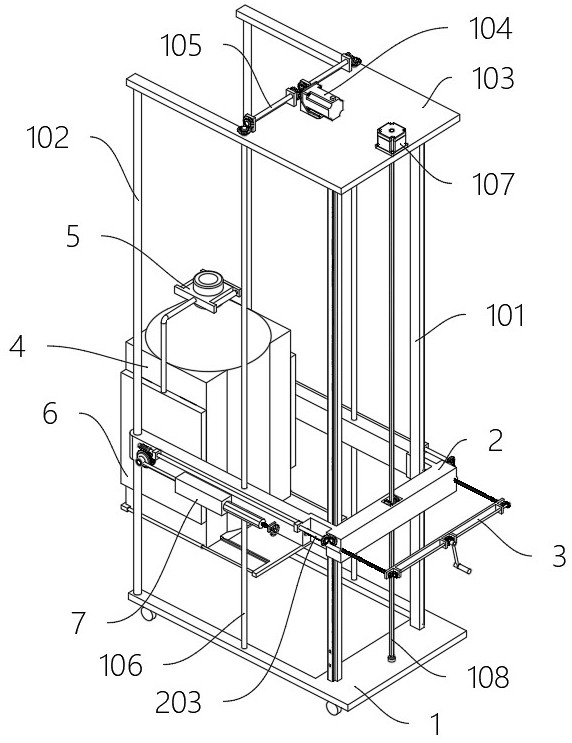

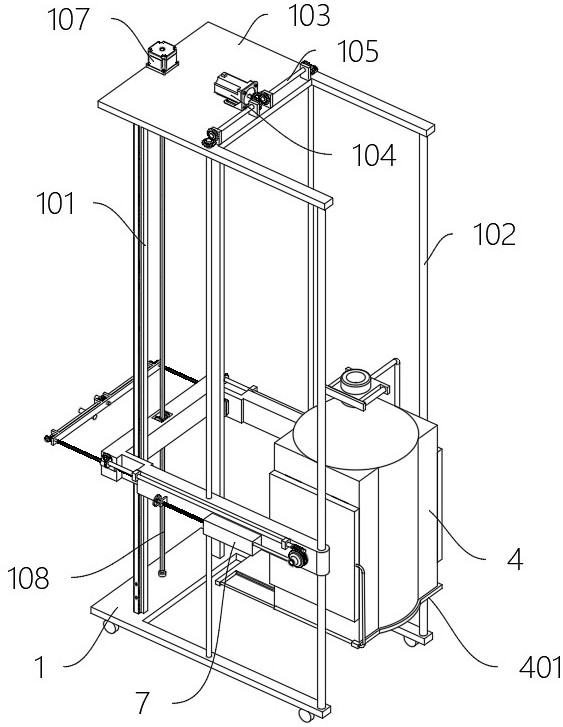

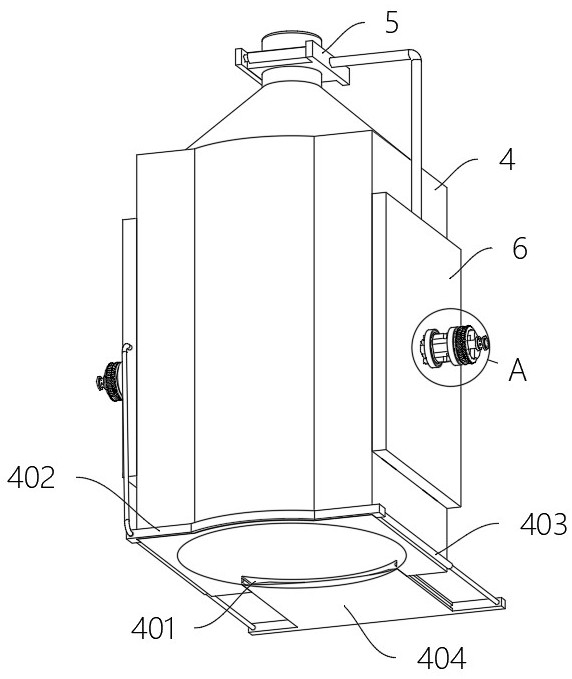

[0035] Example: please refer to Figure 1 to Figure 10 :

[0036] The invention proposes a chemical raw material dumping device based on chemical production, comprising: a moving base 1, four sets of pulleys are arranged at the bottom of the moving base 1, the main body of the moving base 1 is U-shaped; the top rear side of the moving base 1 is fixed Two sets of vertical guide frames 101 are provided; two sets of vertical guide rods 102 are fixedly arranged at the front ends of the tops of both sides of the movable base 1; The vertical guide frame 101 is slidably connected, and the front ends of the two sides of the landing gear 2 are slidably connected with the vertical guide rod 102; Side screw connection; sealing buckle casing 4, the top of the sealing buckle casing 4 is a conical structure, the sealing buckle casing 4 is rotatably arranged in the middle of the front end of the landing gear 2; the air control valve 5, the air control valve 5 is fixedly connected to the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com