Belt cleaning device

A belt cleaning device and belt technology, applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of film fragmentation, falling off, and inability to clean, so as to avoid hardening, ensure cleanliness, and improve The effect of delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the embodiments shown in the accompanying drawings.

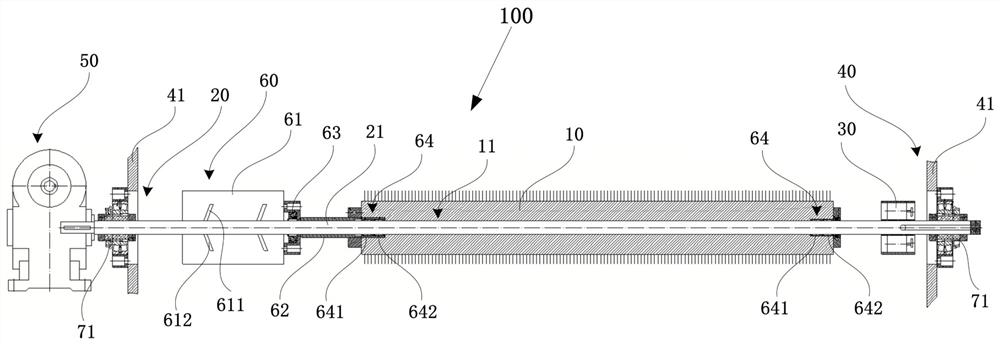

[0027] as attached figure 1 As shown, this embodiment discloses a belt cleaning device 100, which is applied in a belt conveyor to clean the belt. In the belt conveyor, the belt forms an annular structure and is sleeved on the driving wheel and the driven wheel, and the belt is rotated synchronously by driving the driving wheel and the driven wheel to rotate, so as to realize the conveying of the articles. As a specific implementation scenario, the belt conveyor is used in the cigarette production line to convey the shredded tobacco. Therefore, it is necessary to clean up impurities such as smoke foam attached to the belt, so as to facilitate the continuous and efficient processing of the shredded tobacco. delivery.

[0028] Specifically, the belt cleaning device 100 includes: a brush roller 10 and a rotating mechanism 20 .

[0029] The brush ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com