Square steel blanking device for forging of petrochemical mining casing head

A casing head, petrochemical technology, applied in household refrigeration devices, forging/pressing/hammer devices, applications, etc., can solve the problems of high surface temperature, inconvenient transportation, affecting production efficiency, etc., and achieve the effect of accelerating heat dissipation and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

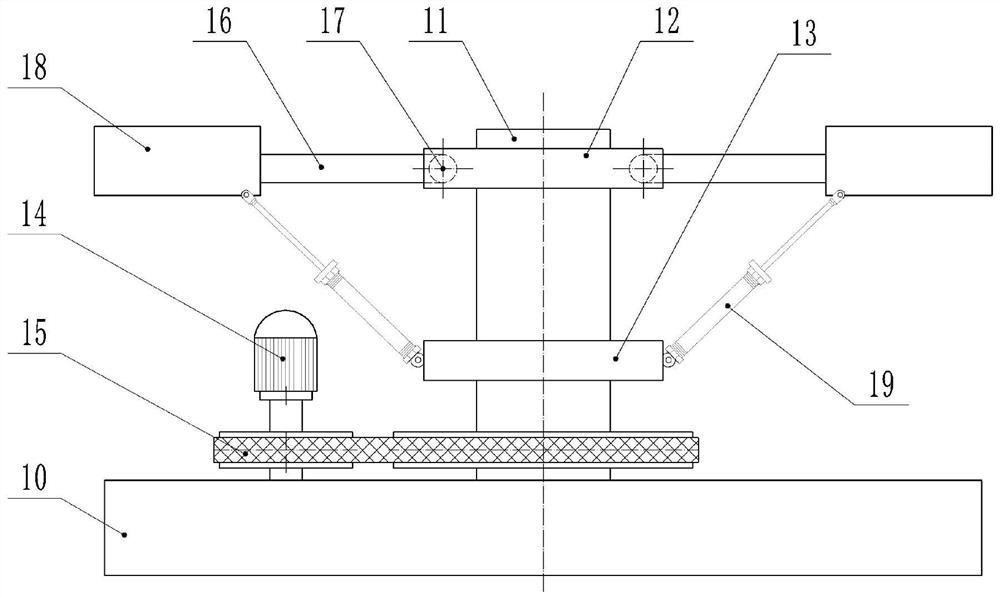

[0023] basically as figure 1 As shown, the square steel blanking device used for forging casing heads for petrochemical mining includes a workbench 10, on which a main shaft 11 is vertically rotatably connected, and on the main shaft 11 are coaxially fixed with a first mounting plate 12 and The second mounting plate 13, wherein the first mounting plate 12 is located above the second mounting plate 13, and a drive unit for driving the main shaft 11 to rotate is provided on the worktable 10; in this embodiment, the drive unit includes a reduction motor 14 and a belt transmission mechanism 15, wherein the belt transmission mechanism 15 includes a driving pulley, a driven pulley and a belt, the driving pulley is coaxially fixed on the output shaft of the deceleration motor 14, and the driven pulley is coaxially fixed on the main shaft 11, and is located in the first Below the two mounting plates 13, the belt connects the driving pulley and the driven pulley.

[0024] In this embo...

Embodiment 2

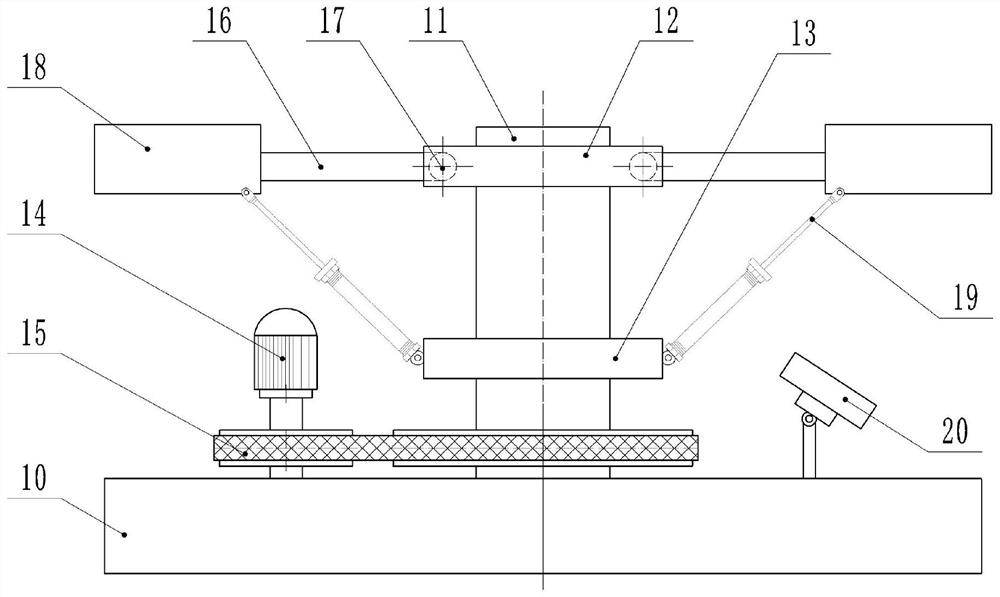

[0030] The difference from Example 1 is that the combination figure 2 As shown, in this embodiment, a cooling fan 20 is also provided on the workbench 10, wherein the cooling fan 20 is located on the connecting line between the main shaft 11 and the material box, and the air outlet of the cooling fan 20 is inclined toward the side of the receiving hopper 18 Setting, the angle of inclination is 30°~40°.

[0031] In this way, when the high-temperature forging is transported, the air flow generated by the cooling fan 20 can act on the bottom of the hopper 18, and since the air outlet of the cooling fan 20 is inclined in this embodiment, it can reduce the drop of the high-temperature forging during the transporting process. The metal chips enter into the cooling fan 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com