High-sulfur-resistance zirconium-based pillared clay supported catalyst as well as preparation method and application thereof

A supported catalyst and pillared clay technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problem of irreversible deactivation of catalysts, achieve high sulfur resistance and alleviate poisoning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] On the one hand, the embodiments of the present application provide a method for preparing a high-sulfur-resistant zirconium-based pillared clay-supported catalyst, which includes the following steps:

[0031] S1, a bentonite suspension with a mass fraction of 0.5-2% and a zirconium oxynitrate cross-linking agent with a concentration of 0.1-0.5 mol / L are configured.

[0032] Wherein, the preparation method of bentonite suspension is as follows: put 5-20g bentonite into a 1L beaker, add 980-995g deionized water as a solvent, and stir at room temperature for 24h to obtain a bentonite suspension with a mass fraction of 0.5-2% liquid.

[0033] The method for preparing zirconium oxynitrate cross-linking agent using zirconium oxynitrate as a zirconium source is as follows: aging 0.1 mol / L zirconium oxynitrate in a constant temperature water bath at 75~90℃ for 3~10h, and then standing for 2~5h to cool down, A zirconium oxynitrate crosslinking agent with a concentration of 0.1...

Embodiment approach

[0042] It includes the following steps:

[0043] S1, configure a bentonite suspension with a mass fraction of 1% and a zirconium oxynitrate crosslinking agent with a concentration of 0.1 mol / L.

[0044] Among them, the preparation method of bentonite suspension is as follows: put 10g bentonite into a 1L beaker, add 990g deionized water as a solvent, and stir at room temperature for 24h to obtain a bentonite suspension with a mass fraction of 1%.

[0045] The method for preparing zirconium oxynitrate crosslinking agent using zirconium oxynitrate as zirconium source is as follows: aging 0.1 mol / L zirconium oxynitrate in a constant temperature water bath at 85°C for 5 hours, and then standing to cool for 3 hours to obtain a concentration of 0.1 mol / L L's zirconium oxynitrate crosslinker.

[0046] The prepared zirconium oxynitrate crosslinking agent is slowly added dropwise to the fully dispersed bentonite suspension to obtain a first mixed solution, ensuring that the concentrati...

Embodiment 1

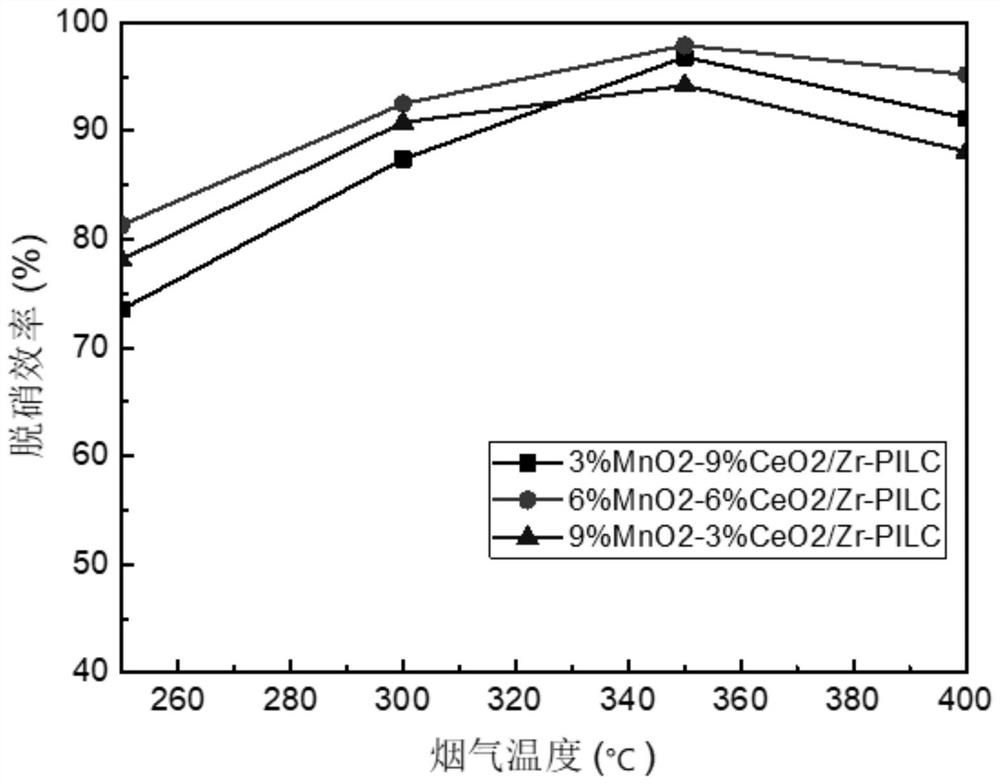

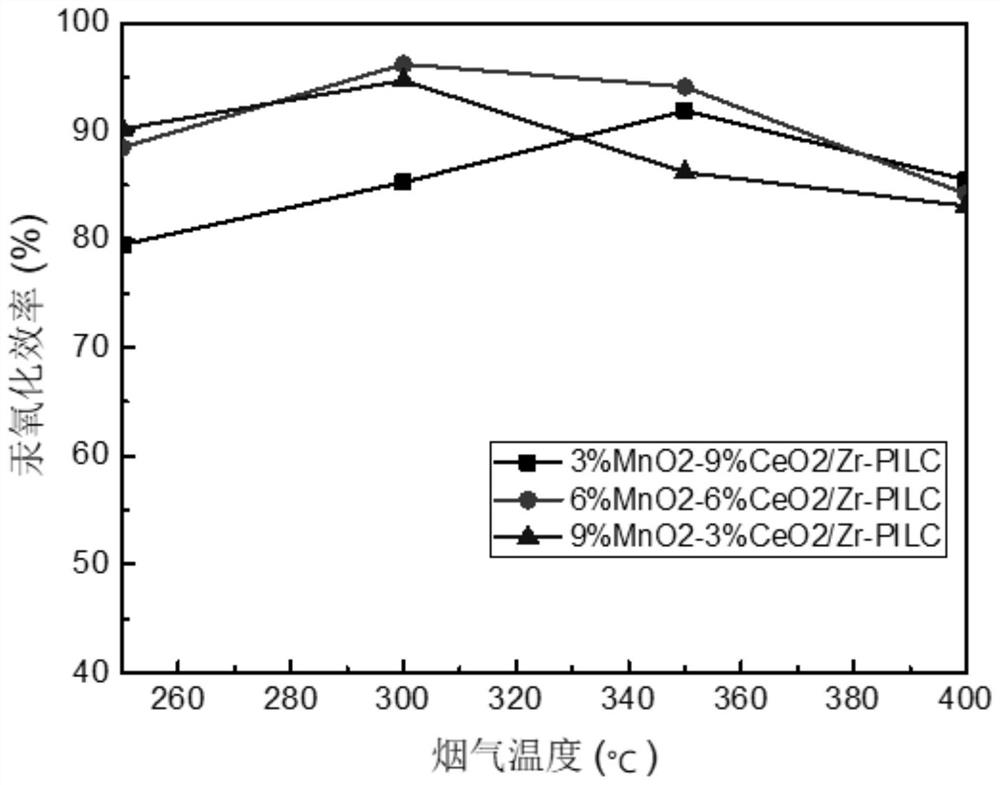

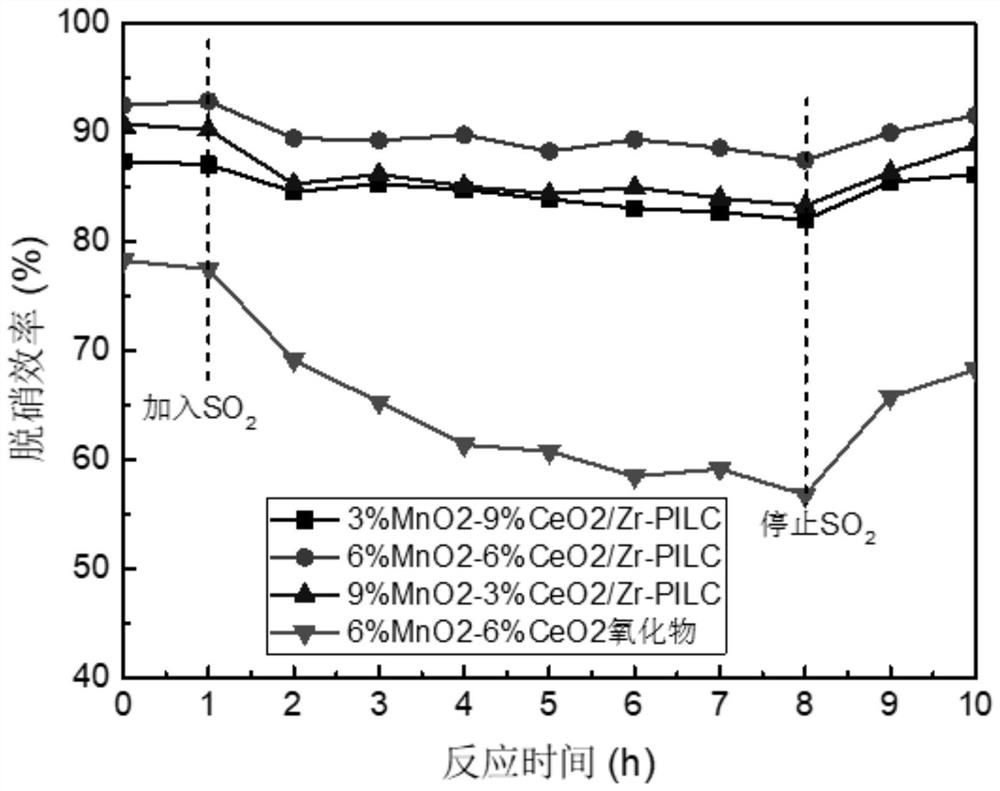

[0061] 6%MnO 2 -6% CeO 2 / Zr-PILC catalyst preparation and performance testing.

[0062] Put 10 g of bentonite into a 1L beaker, add 990 g of deionized water as a solvent, and stir at room temperature for 24 hours to obtain a bentonite suspension with a mass fraction of 1%.

[0063] Use zirconium oxynitrate as zirconium source to prepare zirconium oxynitrate cross-linking agent: prepare 0.1 mol / L zirconium oxynitrate solution, age it in a constant temperature water bath at 85°C for 5 hours, and then stand for 3 hours to cool down to obtain a concentration of 0.1 mol / L L's zirconium oxynitrate crosslinker.

[0064] The prepared zirconium oxynitrate crosslinking agent is slowly added dropwise to the fully dispersed bentonite suspension to obtain a first mixed solution, ensuring that the concentration of zirconium oxynitrate in the first mixed solution is 15mmol / g , stir for 6h at room temperature, and then stand for 12h, so that the zirconium oxynitrate crosslinking agent and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com