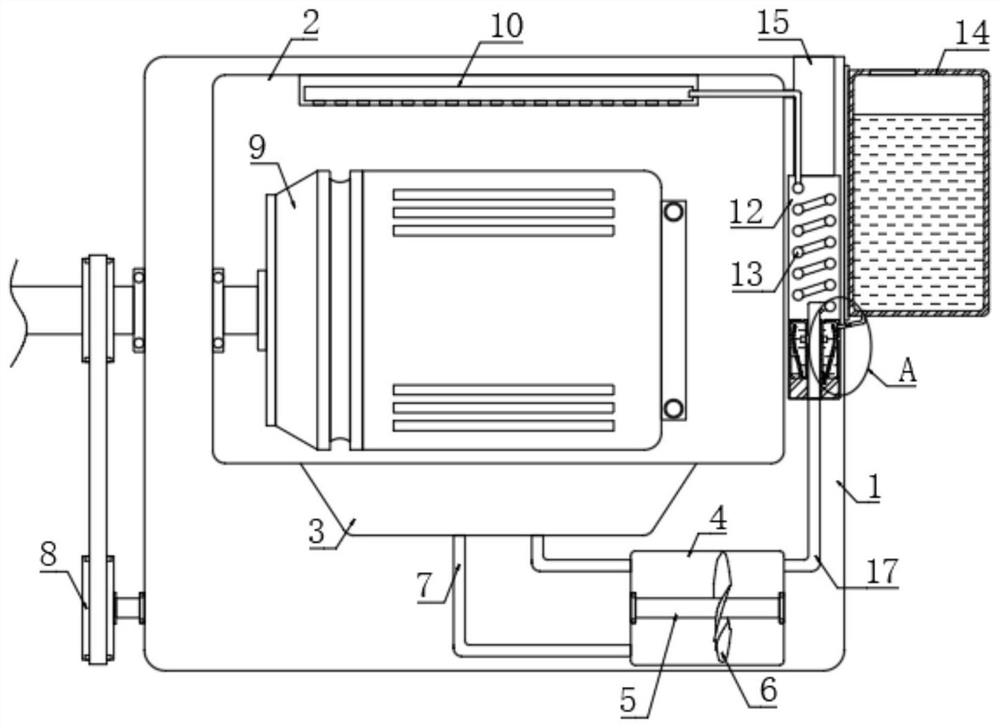

Permanent magnet motor mounting shell with heat dissipation structure

A permanent magnet motor and heat dissipation structure technology, which is applied in the direction of motors, electromechanical devices, casings/covers/supports, etc., can solve the problem of excessive heat in the motor, and achieve the effect of increasing the amount of atomized water and efficient heat dissipation , The effect of increasing the atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

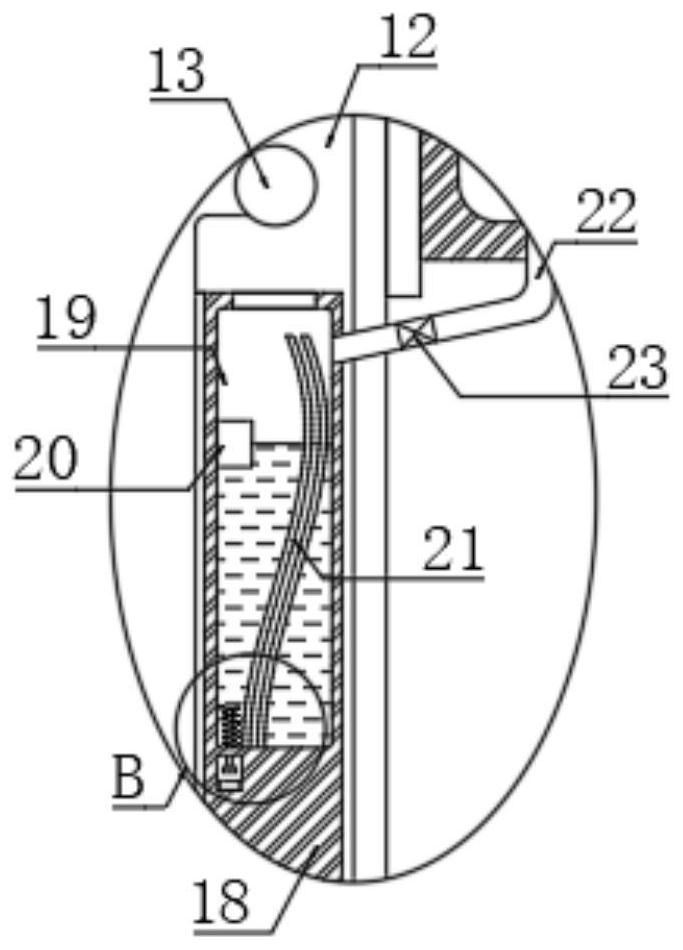

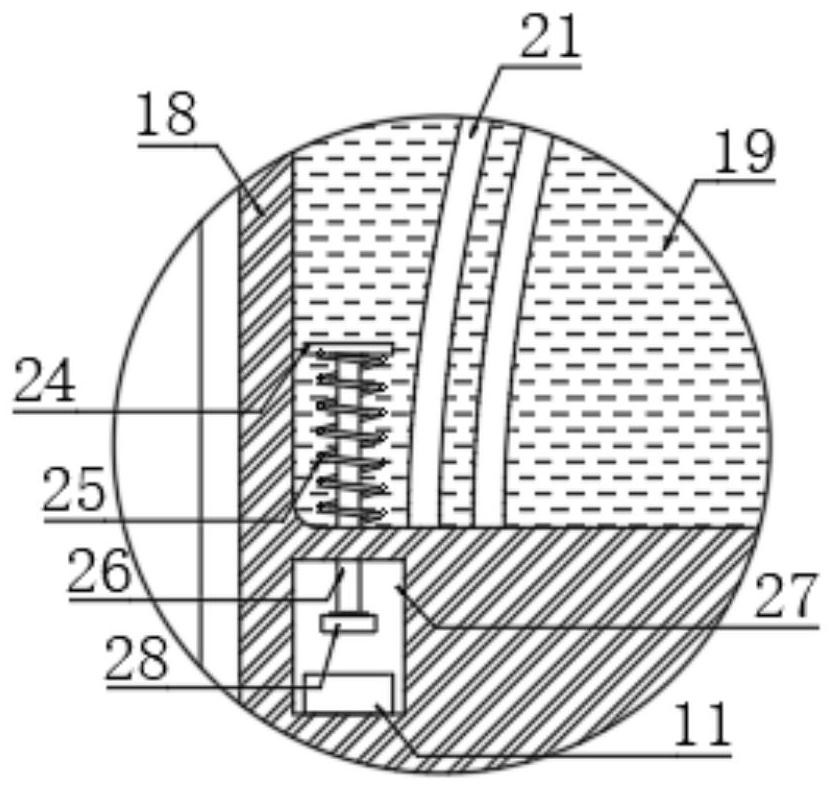

[0029] As an embodiment of the present invention, it also includes an automatic water adding mechanism. The automatic water adding mechanism includes a water storage tank 14 installed on the right side of the housing 1. The inner bottom of the water storage tank 14 communicates with the top space of the annular cavity 19 through the downpipe 22. A trigger cavity 27 is arranged in the chemical box 18, the touch delay switch 11 is installed at the inner bottom of the trigger cavity 27, and a contact block 28 is arranged in the trigger cavity 27. In actual use, the contact block 28 needs to be grounded, thereby After the touch delay switch 11 is touched, the effect of delaying power off is realized. The upper end of the contact block 28 is fixedly connected with a connecting rod 26, and the upper end of the connecting rod 26 extends into the annular cavity 19, and is fixedly connected with the lower pressing plate 24. The lower end of the pressing plate 24 is elastically connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com