Treatment method and system for waste 18650 steel shell lithium ion battery

A technology of a lithium ion battery and a treatment method, which is applied in the field of resource recycling and utilization of waste cylindrical lithium ion battery cells, can solve problems such as low efficiency, and achieve the effects of cost reduction, efficient recovery and reduction of enrichment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

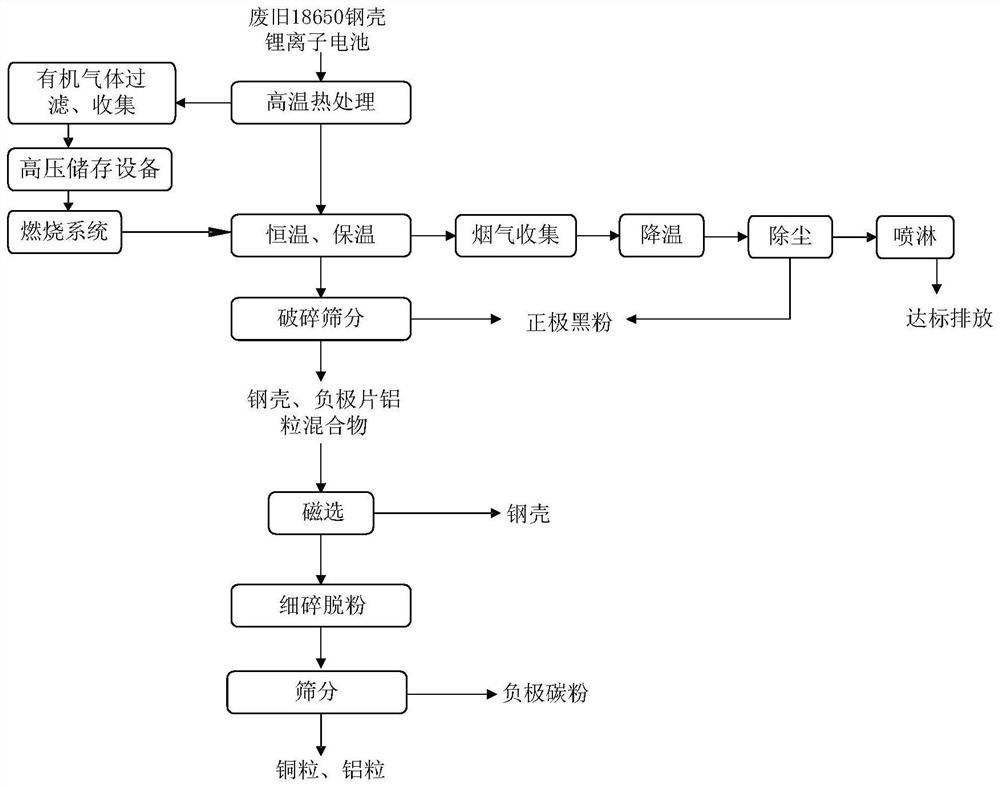

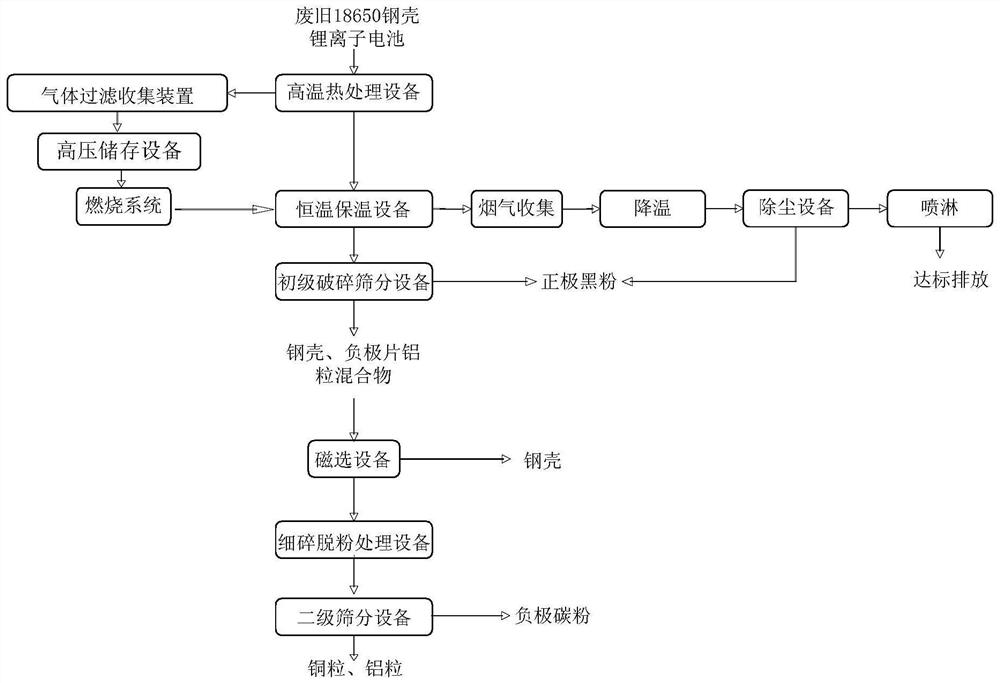

[0071] see figure 1 , a method for treating waste 18650 steel shell lithium-ion batteries, comprising the following steps:

[0072] Step 1: Send the collected waste 18650 steel shell lithium-ion battery directly into the high temperature heat treatment section, the heating temperature is controlled at 750°C, the waste lithium-ion battery reaches 650°C within 5s, and the volume of organic components in the electrolyte inside the battery is sharp. Expansion and overflow, the residual power of the battery is quickly released after the overflow; the organic components collected and overflowed are filtered to obtain organic gas, and the organic gas is collected into a high-pressure storage device;

[0073] Step 2: After the organic components are completely overflowed, enter the constant temperature heat preservation treatment, and the temperature is controlled at 700 ° C; in this step, add the organic gas in the high pressure storage device of step 1 to the constant temperature he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com