Application of additive capable of removing active oxygen species in lithium ion battery

A technology of lithium-ion batteries and additives, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of poor battery cycle performance and rate performance, reduce electrolyte oxidation, achieve high-rate charge and discharge performance, and avoid battery damage. The effect of overcharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

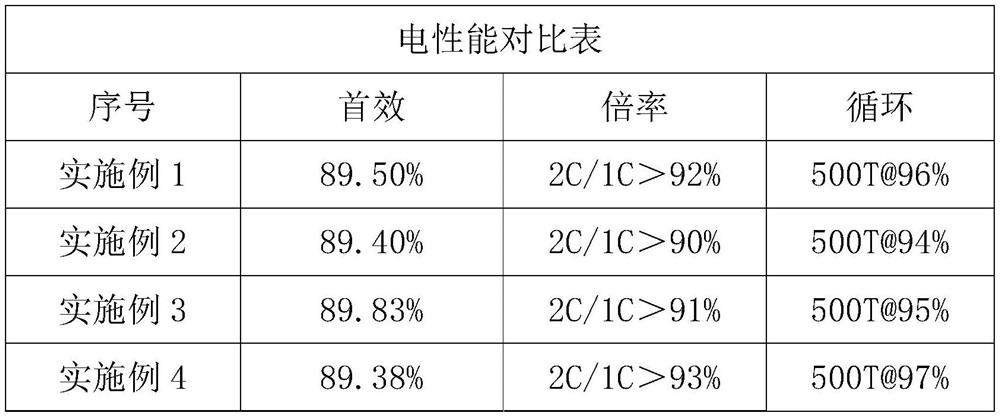

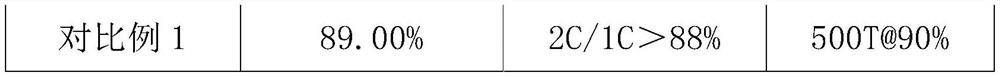

Examples

Embodiment 1

[0018] (1) Preparation of positive electrode sheet

[0019] The cathode active material LiNi 0.8 Co 0.1 Mn 0.1 O 2 , Adhesive polyvinylidene fluoride, conductive agent acetylene black are prepared according to the mass ratio of 97:1.5:1.5, first add polyvinylidene fluoride to a certain amount of N-methylpyrrolidone to dissolve, and then add LiNi 0.8 Co 0.1 Mn 0.1 O 2 The powder and acetylene black are stirred and mixed under the action of vacuum stirring to form a positive electrode slurry with uniform fluidity. The positive electrode slurry is uniformly coated on the aluminum foil current collector with a thickness of 12 μm, and is dried in an oven with five different temperature gradients. After baking, it was placed in a vacuum oven at 120° C. for 8 hours, and after rolling and slitting, a positive electrode sheet for assembling a lithium ion battery was obtained. Using NaVPO in a similar way 4 F was used as a positive electrode active material to obtain a positive ...

Embodiment 2

[0029] (1) Preparation of positive electrode sheet

[0030] The cathode active material LiNi 0.8 Co 0.1 Mn 0.1 O 2 , Adhesive polyvinylidene fluoride, conductive agent acetylene black are prepared according to the mass ratio of 97:1.5:1.5, first add polyvinylidene fluoride to a certain amount of N-methylpyrrolidone to dissolve, and then add LiNi 0.8 Co 0.1 Mn 0.1 O 2 The powder and acetylene black are stirred and mixed under the action of vacuum stirring to form a positive electrode slurry with uniform fluidity. The positive electrode slurry is uniformly coated on the aluminum foil current collector with a thickness of 12 μm, and is dried in an oven with five different temperature gradients. After baking, it was placed in a vacuum oven at 120° C. for 8 hours, and after rolling and slitting, a positive electrode sheet for assembling a lithium ion battery was obtained. Using NaVPO in a similar way 4 F was used as a positive electrode active material to obtain a positive ...

Embodiment 3

[0040] (1) Preparation of positive electrode sheet

[0041] The cathode active material LiNi 0.8 Co 0.1 Mn 0.1 O 2 , Adhesive polyvinylidene fluoride, conductive agent acetylene black are prepared according to the mass ratio of 97:1.5:1.5, first add polyvinylidene fluoride to a certain amount of N-methylpyrrolidone to dissolve, and then add LiNi 0.8 Co 0.1 Mn 0.1 O 2 The powder and acetylene black are stirred and mixed under the action of vacuum stirring to form a positive electrode slurry with uniform fluidity. The positive electrode slurry is uniformly coated on the aluminum foil current collector with a thickness of 12 μm, and is dried in an oven with five different temperature gradients. After baking, it was placed in a vacuum oven at 120° C. for 8 hours, and after rolling and slitting, a positive electrode sheet for assembling a lithium ion battery was obtained. Using NaVPO in a similar way 4 F was used as a positive electrode active material to obtain a positive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com