Sodium-ion battery additive and high-power sodium-ion battery

A sodium-ion battery and additive technology, applied in the field of materials, can solve the problems of short battery life and high safety hazards, and achieve the effect of reducing internal resistance and improving the migration performance of sodium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

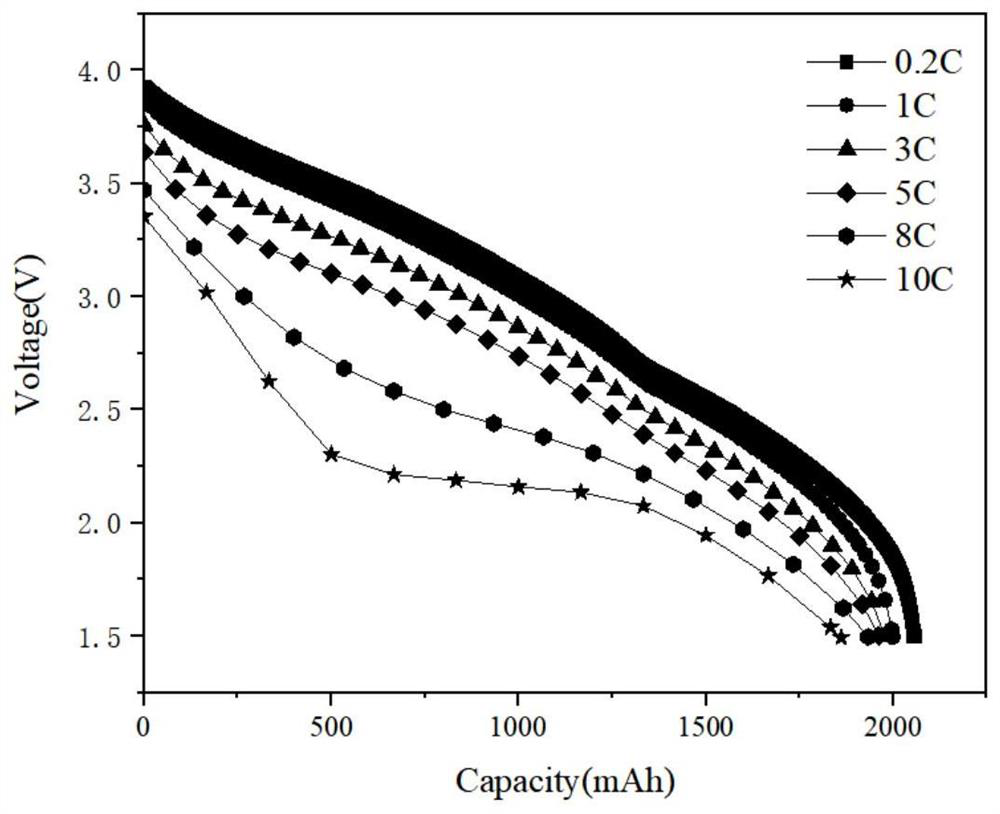

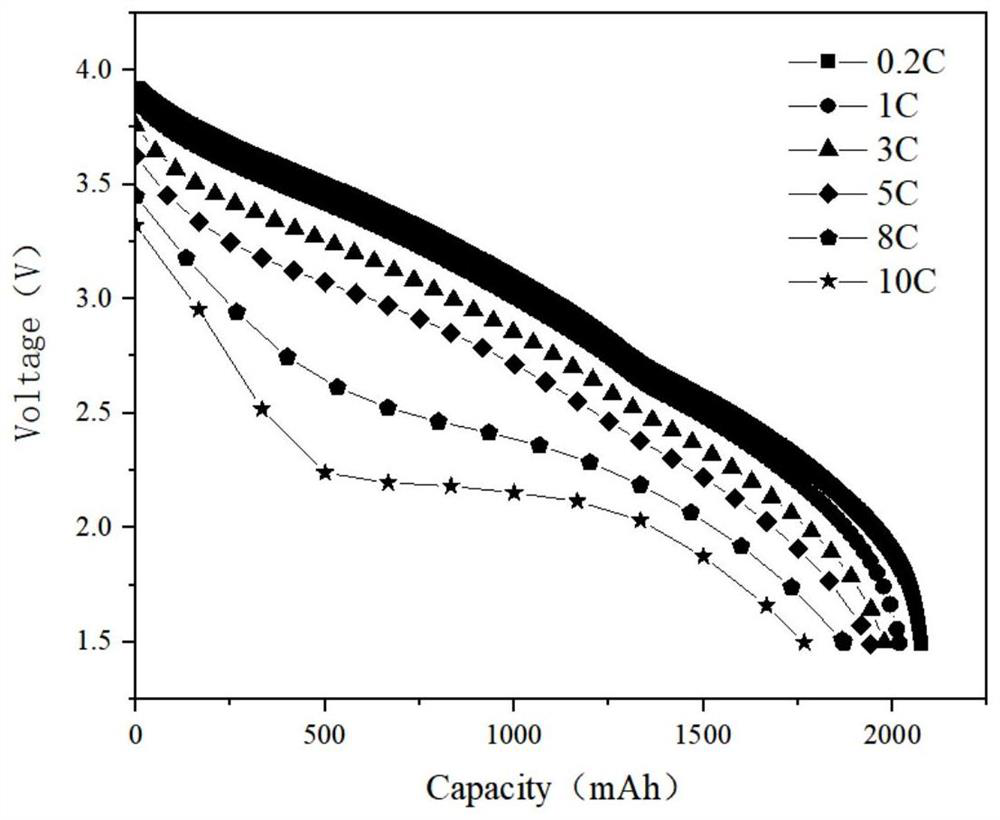

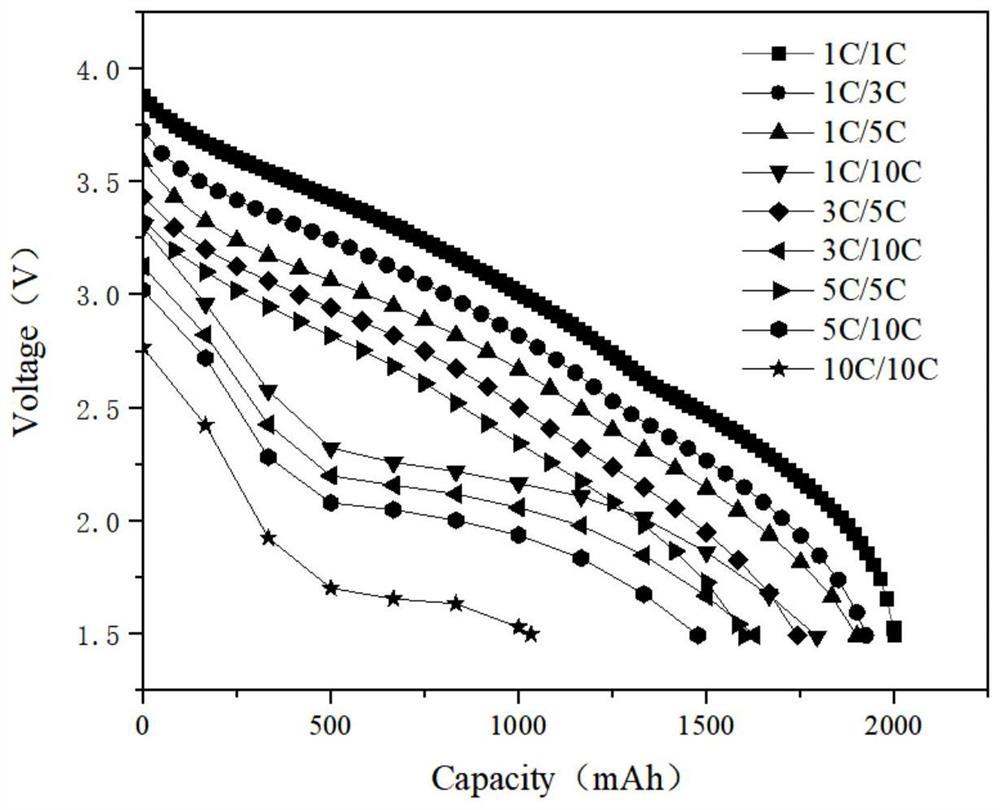

Image

Examples

Embodiment 1

[0049] Preparation of positive pole piece: add 100wt% solvent N-methylpyrrolidone (NMP) and 5wt% binder polyvinylidene fluoride (PVDF) powder into the planetary stirring cylinder, rotate at 30r / min, disperse at 3000r / min speed Stir for 2 hours, then add 5wt% of conductive agent carbon black (SP), stir for 1 hour at the speed of revolution 30r / min, dispersion 3000r / min, then add 5wt% Na-β-alumina, press revolution 30r / min , stirring at a speed of 3000r / min for 1 hour, and then adding 85wt% of the positive active material O3-Na[Cu 0.22 Fe 0.3 Mn 0.48 ]O 2 , and stir for 3 hours at 30 r / min revolution and 3000 r / min dispersion, then defoaming and sieving through a 200-mesh sieve to complete the preparation of the positive electrode slurry for sodium ion batteries;

[0050] The positive electrode slurry prepared above was evenly coated on an aluminum foil with a thickness of 15 μm by means of extrusion, and was dried, rolled and cut to prepare a positive electrode pole piece. ...

Embodiment 2

[0055] The 26650 cell was prepared by the same method as in Example 1. The difference from Example 1 is that in the positive and negative electrode materials, the proportion of Na-β-alumina is 10wt%, and the proportion of positive and negative active materials is both 80wt% %, number A2.

Embodiment 3

[0057] The 26650 cell was prepared by the same method as in Example 1. The difference from Example 1 is that in the positive and negative electrode materials, the proportion of Na-β-alumina is 15wt%, and the proportion of positive and negative electrode active materials is both 75wt% %, number A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com