Method for producing lithium ion battery of high magnification

A lithium-ion battery, high-rate technology, applied in the manufacture of battery electrodes, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problem of adding pole piece production processes and time, introducing edge metal scraps into batteries, increasing production equipment and costs, etc. Problems, to achieve the effect of high rate charge and discharge performance, easy control and realization, and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Using lithium iron phosphate as the positive electrode material and graphite as the negative electrode material to produce 80Ah plastic case lithium-ion batteries. Lithium iron phosphate is selected as the electrode sheet of the positive electrode material, and the surface density of double-sided coating is 35mg / cm 2 , with a compacted density of 2 g / cm 3 . After liquid injection, the bottom of the battery stands on the ground for 26 hours, then the front of the battery is placed on the ground for 2 hours, and then the left side, the right side, and the back are placed on the ground in the same way for 2 hours, and finally the bottom of the battery is placed on the ground for 2 hours. , the total standing time is 36h, and then carry out chemical composition test.

Embodiment 2

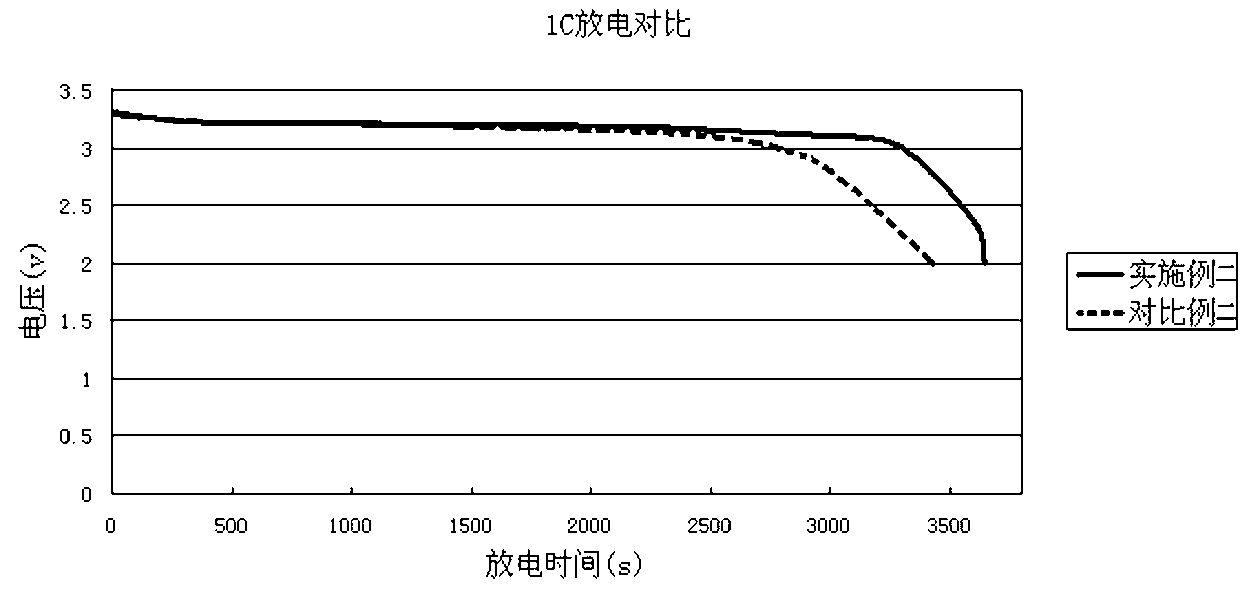

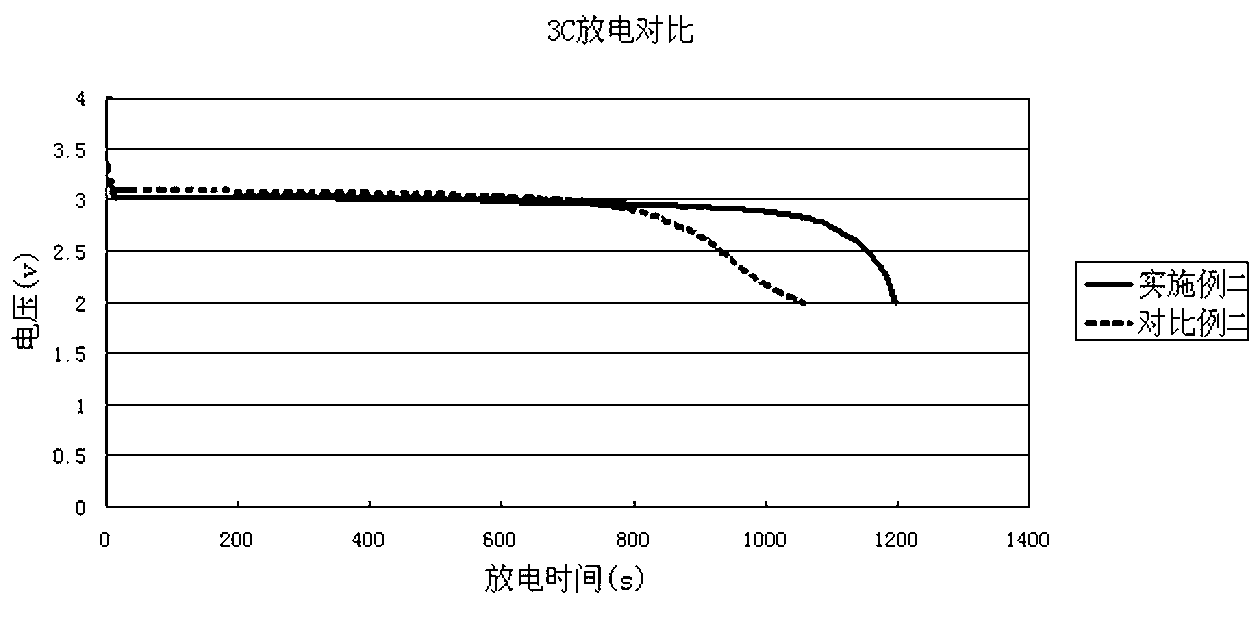

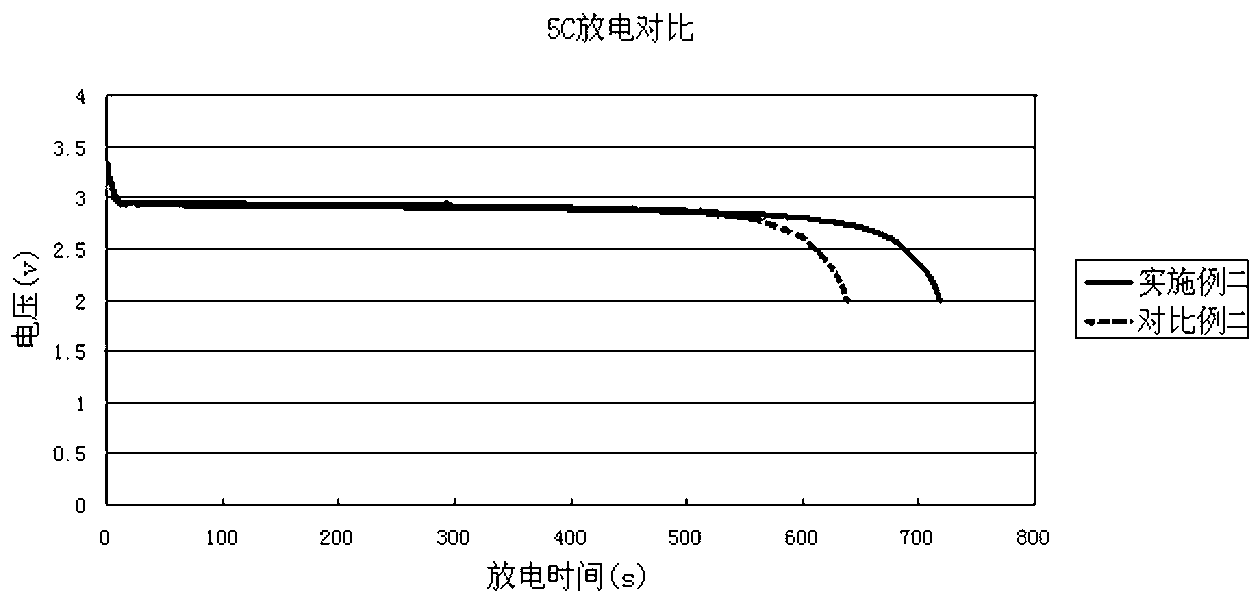

[0024] Using lithium iron phosphate as the positive electrode material and graphite as the negative electrode material to produce 80Ah plastic case lithium-ion batteries. Double-sided coating surface density 33 mg / cm 2 , compacted density 2.04 mg / cm 3 . After liquid injection, the bottom of the battery stands on the ground for 26 hours, then the front of the battery is placed on the ground for 2 hours, and then the left side, the right side, and the back are placed on the ground in the same way for 2 hours, and finally the bottom of the battery is placed on the ground for 2 hours. , the total standing time is 36h, the rate discharge performance data of the obtained battery is shown in the table below.

[0025] initial capacity 1C discharge 3C discharge 5C discharge 7C discharge 1C charging 3C charging Embodiment two 80.625Ah 81.129Ah 79.832Ah 79.812Ah 78.9Ah 78.916Ah 68.741Ah

Embodiment 3

[0031] Using lithium iron phosphate as the positive electrode material and graphite as the negative electrode material to produce 80Ah plastic case lithium-ion batteries. Lithium iron phosphate is selected as the electrode sheet of the positive electrode material, and the surface density of double-sided coating is 30mg / cm 2 , with a compacted density of 2.05 g / cm 3 . After liquid injection, the bottom of the battery stands on the ground for 20 hours, then the front of the battery is placed on the ground for 1 hour, and then the left side, the right side, and the back are placed on the ground in the same way for 1 hour, and finally the bottom of the battery is placed on the ground for 1 hour. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com