Whey protein peptide and high-F-value oligopeptide with liver injury protection effect as well as preparation method and application of whey protein peptide and high-F-value oligopeptide

A whey protein peptide and protease technology, applied in the field of active peptides, can solve the problems of poor reproducibility, difficulty in large-scale production, and low efficiency, and achieve the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

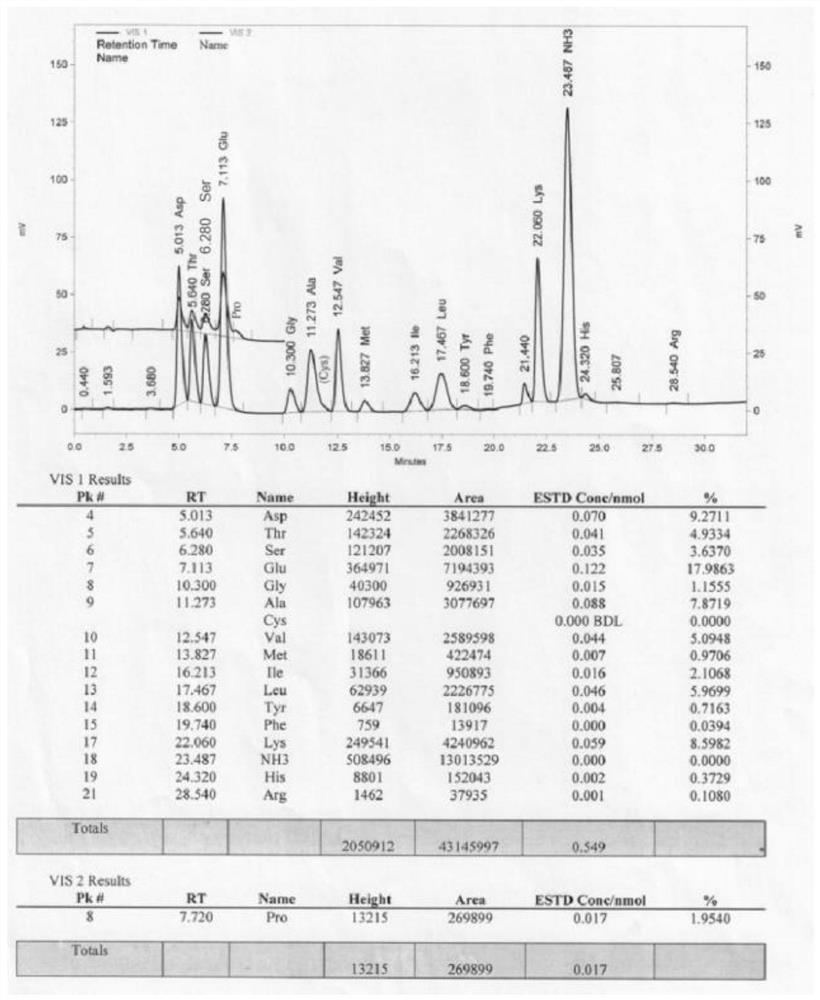

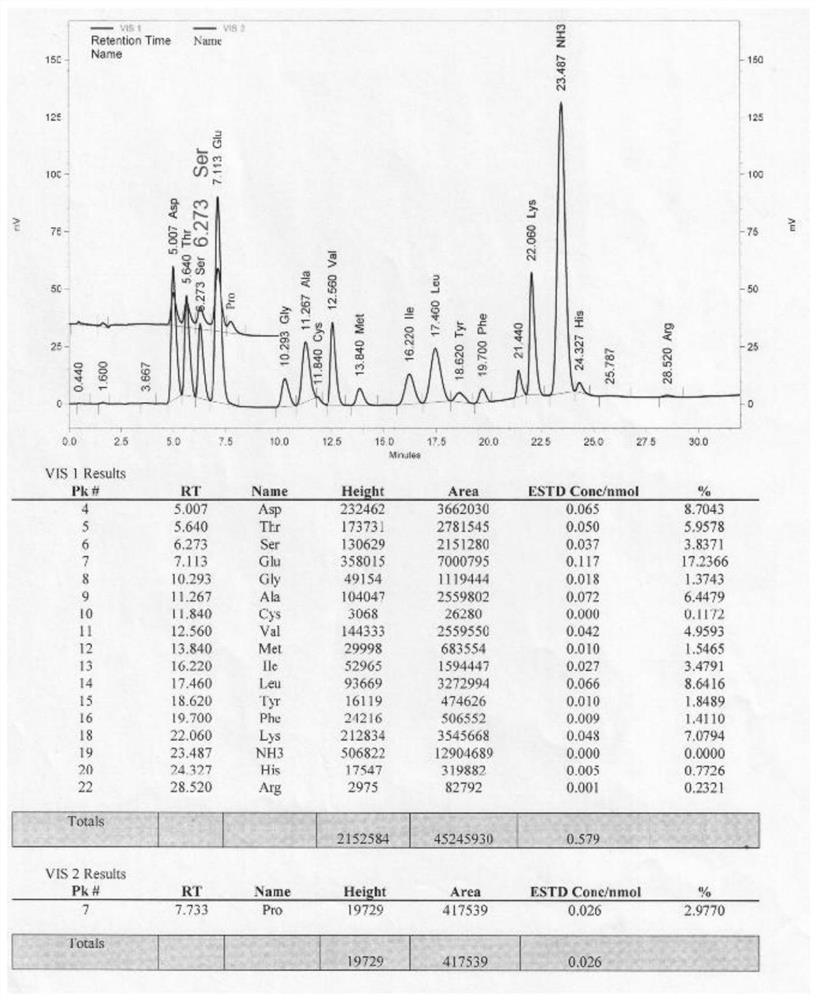

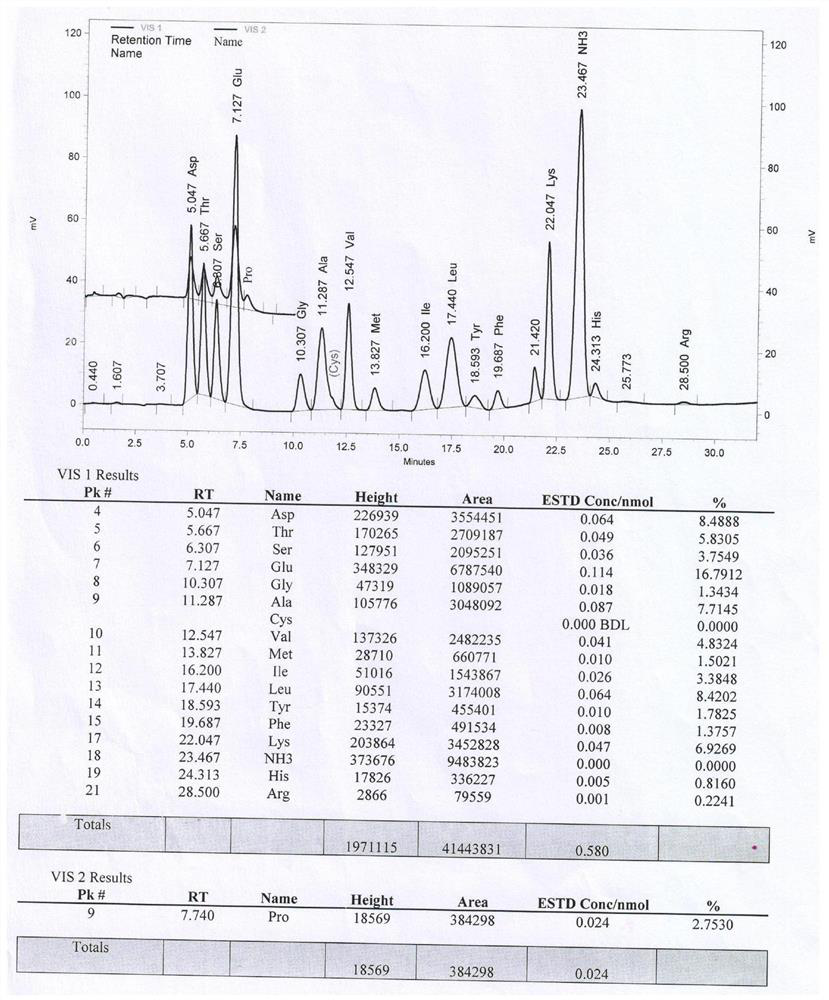

Image

Examples

preparation example Construction

[0035] The present invention provides a method for preparing a whey protein peptide, comprising the following steps: after pre-treating whey protein with alkaline protease, exposing the aromatic amino acid of the peptide chain at the C-terminus or N-terminus with endoprotease, and then Exoprotease is used to hydrolyze the exposed aromatic amino acids to obtain an enzymatic hydrolysis solution; the enzymatic hydrolysis solution is subjected to ion exchange column chromatography to collect a permeate, wherein the permeate contains the whey protein peptide.

[0036] The present invention utilizes alkaline protease to pretreat whey protein, and the pretreatment includes performing first enzymatic hydrolysis on whey protein with alkaline protease under alkaline conditions to obtain a first enzymatic hydrolysis solution. The pH value of the first enzymatic hydrolysis system of the present invention is preferably about 8.5, and the temperature of the first enzymatic hydrolysis is pref...

Embodiment 1

[0047] Step 1. Alkaline protease pretreatment

[0048] Measure 6L of deionized water, adjust its pH to about 8.5 with 1M NaOH, raise the temperature to 55°C, weigh 0.5g of alkaline protease, and slowly add 500g of whey protein after stirring evenly, stirring continuously at 45 r / min. , to obtain the first enzymatic hydrolyzate;

[0049] Step 2. Further treatment with endonuclease

[0050] During the reaction of the first enzymatic hydrolysis solution, the pH was continuously detected during the period. When the pH dropped to about 7.0 to 7.5, and the temperature dropped to 37 to 42 °C at the same time, 6.5 g of trypsin was weighed, and after enzymatic hydrolysis for 2 hours, the second enzymatic hydrolysis was obtained. liquid;

[0051] Step 3. Exonuclease treatment

[0052] Weigh 1.5 g of flavor protease, add it to the second enzymatic hydrolysis solution, continue enzymatic hydrolysis for 4 hours, heat up to 100 °C, and kill the enzyme for 10 min to obtain the third enzym...

Embodiment 2

[0111] Activation rate assay for alcohol dehydrogenase (ADH)

[0112] Alcohol dehydrogenase (ADH) catalyzes the dehydrogenation of ethanol to form acetaldehyde in the weak base range in the presence of oxidative aldehyde coenzyme I (NAD+) as follows:

[0113]

[0114] The present invention adopts the Waller-Hooch method with slight modifications to determine the inhibitory activity of high F-value whey protein peptides to alcohol dehydrogenase; prepare a 5mL test tube, add 1.5mL of pH8.8 sodium pyrophosphate buffer, 27mmol / L-oxidative coenzyme I (NAD+) 1.0 mL, 11.5% ethanol solution 0.5 mL, test sample 0.1 mL (50 μg / mL sample solution or ultrapure water), the above samples are mixed evenly and placed in a 25°C water bath The pot was warmed for 5 min, and finally 0.1 mL of alcohol dehydrogenase (ADH, 0.25 U / mL) in a 25°C warm bath was added to the test tube. Use a multi-function microplate reader to measure the absorbance at a wavelength of 340nm, measure the absorbance ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com