Wet repair and regeneration method for waste lithium iron phosphate positive electrode material

A technology of lithium iron phosphate and cathode material, which is applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problem that the electrochemical performance of battery materials is far away, the economic value and environmental benefits are not high, and the cycle performance of materials is affected, etc. problems, to achieve the effect of eliminating chemical pollution, short sintering time and saving dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

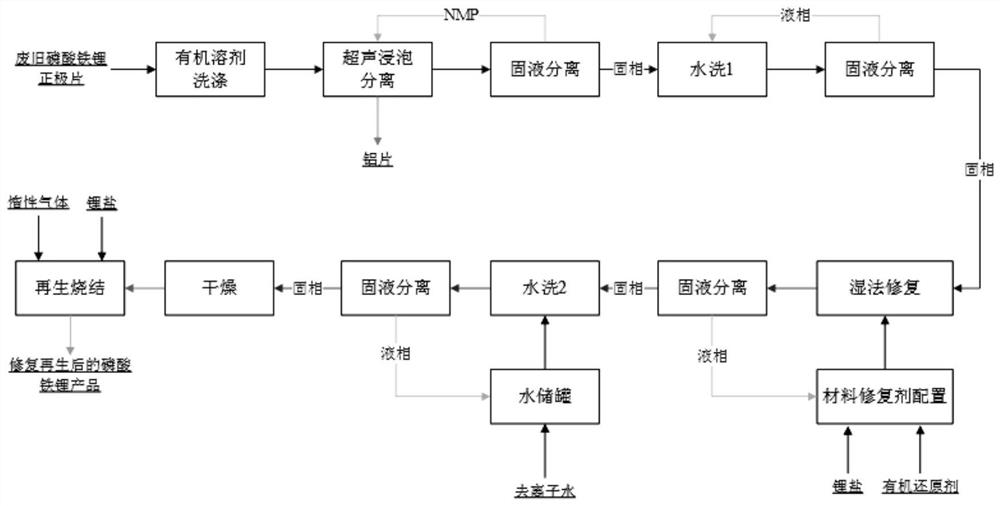

[0051] Embodiment 1 provides a kind of method for wet repair and regeneration of waste lithium iron phosphate positive electrode material, such as figure 1 , including the following steps:

[0052] Step S1, soak the waste lithium iron phosphate positive electrode sheet with an organic solvent, and obtain a clean lithium iron phosphate positive electrode sheet after drying:

[0053] Specifically, the waste lithium iron phosphate positive electrode sheet is the positive electrode sheet obtained after recycling and disassembling the waste lithium iron phosphate battery, the lithium iron phosphate positive electrode scrap in the battery production process, and the lithium iron phosphate positive electrode obtained after the dismantling of the defective battery one or more of the films;

[0054] The organic solvent is ethyl methyl carbonate (EMC), and the soaking time is 5-15min to remove residual electrolyte, which may be LiPF 6 , LiClO 4 , LiBF 4 , LiAsF 6 Wait for lithium s...

Embodiment 2

[0068] Embodiment 2 provides a kind of method for wet repair and regeneration of waste and old lithium iron phosphate positive electrode material, such as figure 1 , including the following steps:

[0069] Step S1, soak the waste lithium iron phosphate positive electrode sheet with an organic solvent, and obtain a clean lithium iron phosphate positive electrode sheet after drying:

[0070] Specifically, the waste lithium iron phosphate positive electrode sheet is the positive electrode sheet obtained after recycling and disassembling the waste lithium iron phosphate battery, the lithium iron phosphate positive electrode scrap in the battery production process, and the lithium iron phosphate positive electrode obtained after the dismantling of the defective battery one or more of the films;

[0071] The organic solvent is ethyl methyl carbonate (EMC), and the soaking time is 5-15min to remove residual electrolyte, which may be LiPF 6 , LiClO 4 , LiBF 4 , LiAsF 6 Wait for l...

Embodiment 3

[0085] Embodiment 3 provides a kind of method for wet repair and regeneration of waste lithium iron phosphate positive electrode material, such as figure 1 , including the following steps:

[0086] Step S1, soak the waste lithium iron phosphate positive electrode sheet with an organic solvent, and obtain a clean lithium iron phosphate positive electrode sheet after drying:

[0087] Specifically, the waste lithium iron phosphate positive electrode sheet is the positive electrode sheet obtained after recycling and disassembling the waste lithium iron phosphate battery, the lithium iron phosphate positive electrode scrap in the battery production process, and the lithium iron phosphate positive electrode obtained after the dismantling of the defective battery one or more of the films;

[0088] The organic solvent is ethyl methyl carbonate (EMC), and the soaking time is 5-15min to remove residual electrolyte, which may be LiPF 6 , LiClO 4 , LiBF 4 , LiAsF 6 Wait for lithium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com