Laminated tempered glass processing technology

A technology of tempered glass and processing technology, applied in glass production, climate change adaptation, chemical instruments and methods, etc., can solve the problems of reducing glass quality and air bubbles, and achieve the effect of improving production efficiency, pushing out air bubbles and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

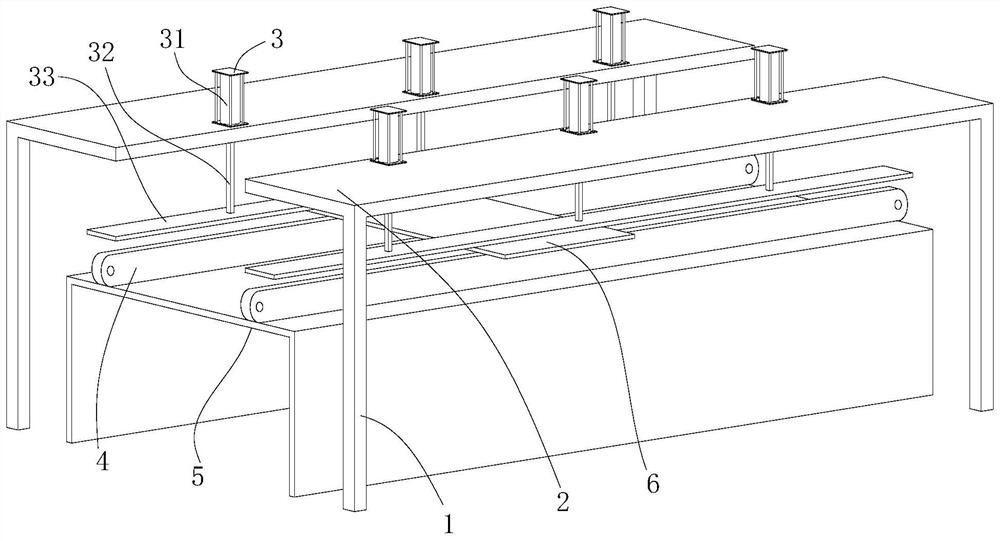

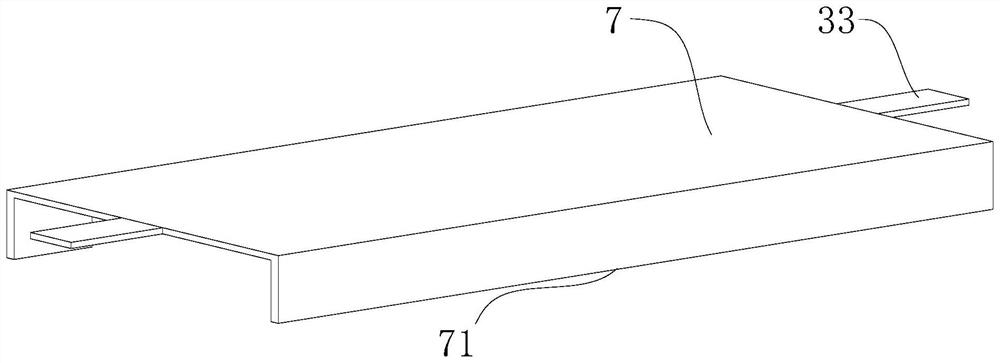

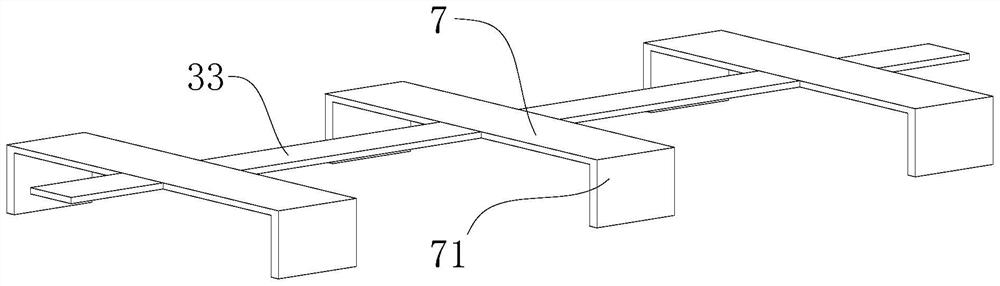

[0038] Attached below Figure 1-7 The present invention is further described with examples:

[0039] A processing technology for laminated tempered glass, comprising the following steps:

[0040] Step 1: Glass cutting and blanking, edging and cleaning of the cut glass;

[0041] Step 2: send the cleaned glass into a tempering furnace for tempering treatment;

[0042] Step 3: Lay the sheets together, cover the PVB film on the bottom glass, and then cover the upper glass on the PVB film;

[0043] Step 4: Send the laminated glass into the roller press;

[0044] Step 5: send the extruded laminated glass into the autoclave for segmented heating and pressure treatment;

[0045] The roller press in step 4 includes a support column 1 and a transverse plate 2, the upper end of the support column 1 is provided with a transverse plate 2, and the transverse plate 2 is provided with a pressing mechanism 3, and a transmission is provided directly below the pressing mechanism 3 Assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com