Device for measuring bending of saw wire of wire saw machine tool

A machine tool and bending technology, applied in the cutting field of semiconductor hard and brittle materials, can solve the problems of difficulty in determining the feed speed, saw wire breakage, and affecting processing efficiency, etc., to increase the feed speed, reduce the feed speed, and improve the cutting efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

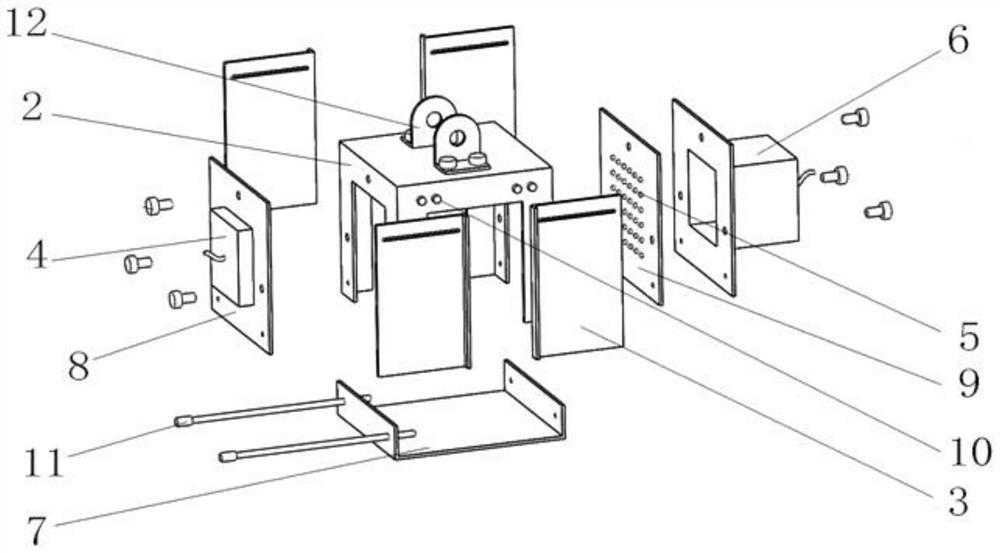

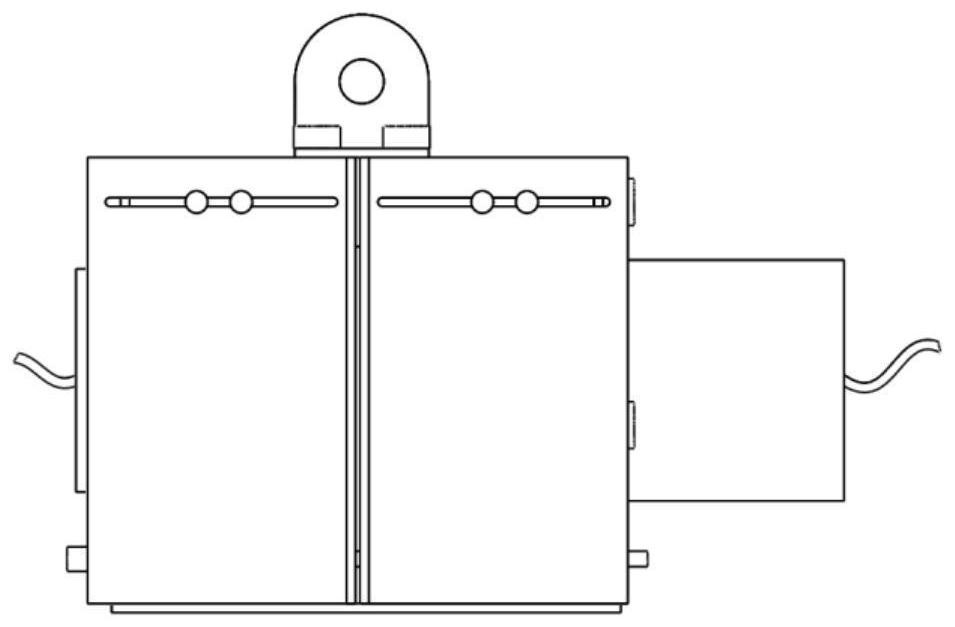

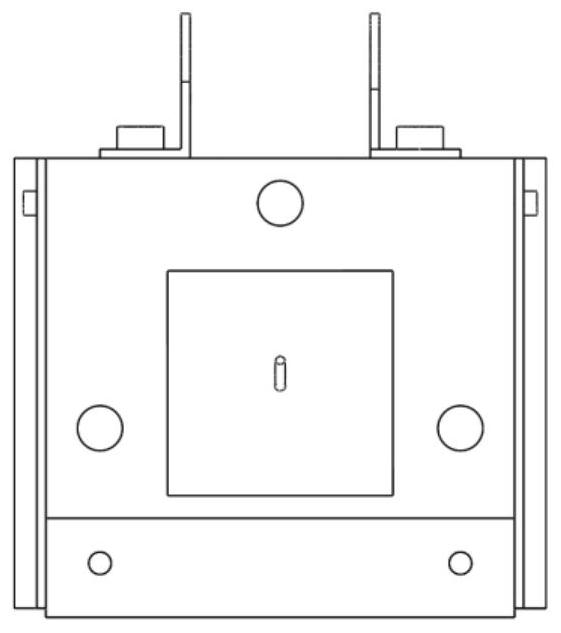

[0033] refer to Figure 1-5 , A device for measuring saw wire bending for a wire saw machine, comprising a device body 1, the top of the bracket 2 is provided with a lifting lug 12 for connecting with the machine tool, and the lifting lug 12 fixes the present invention on the machine tool through bolts. The device body 1 includes a bracket 2, which consists of a fixing plate at the upper end and uprights fixed at the four corners of the bottom of the fixing plate, wherein the four uprights are provided with fixing through holes in the left and right directions at the bottom of the fixing plate. The bottom of the bracket 2 is movably provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com