Predictive control system and method for card pump washing process in a pump plant

A predictive control, pulp mill technology, applied in pulp beating/refining method, washing/replacing pulp treatment liquid, fine split raw material pretreatment, etc., can solve unreliable, difficult correction problems, etc., to reduce energy costs, Effect of reducing bleaching cost and improving pulp quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

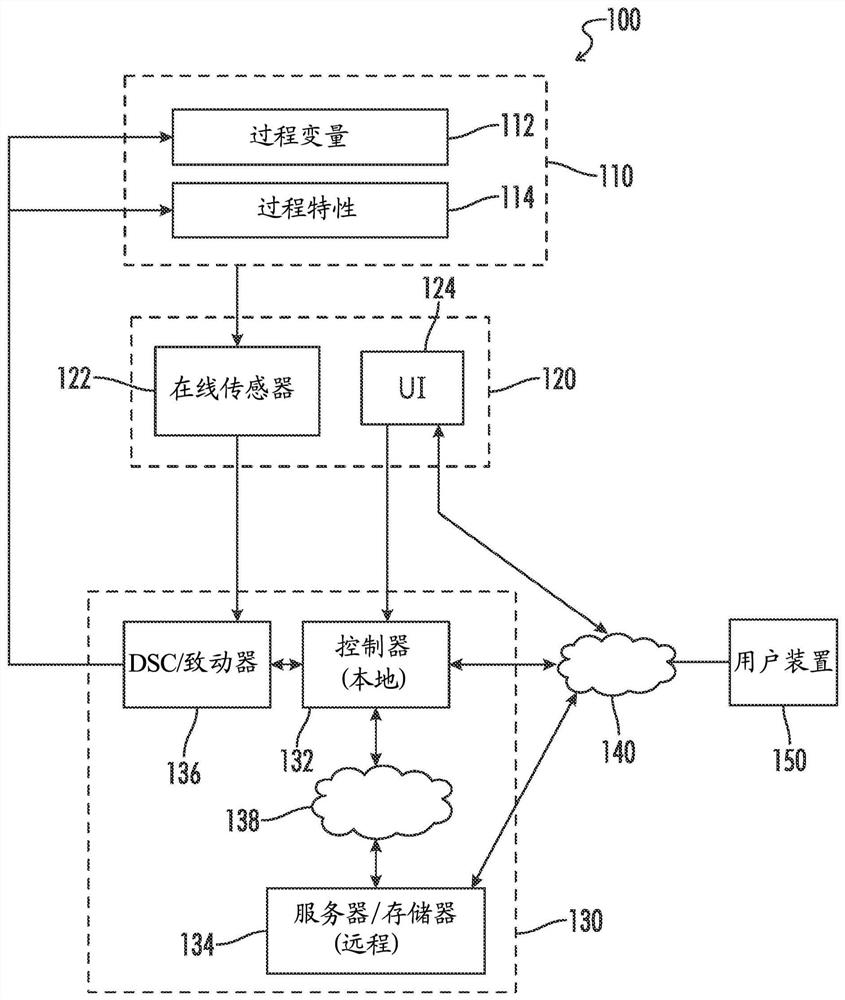

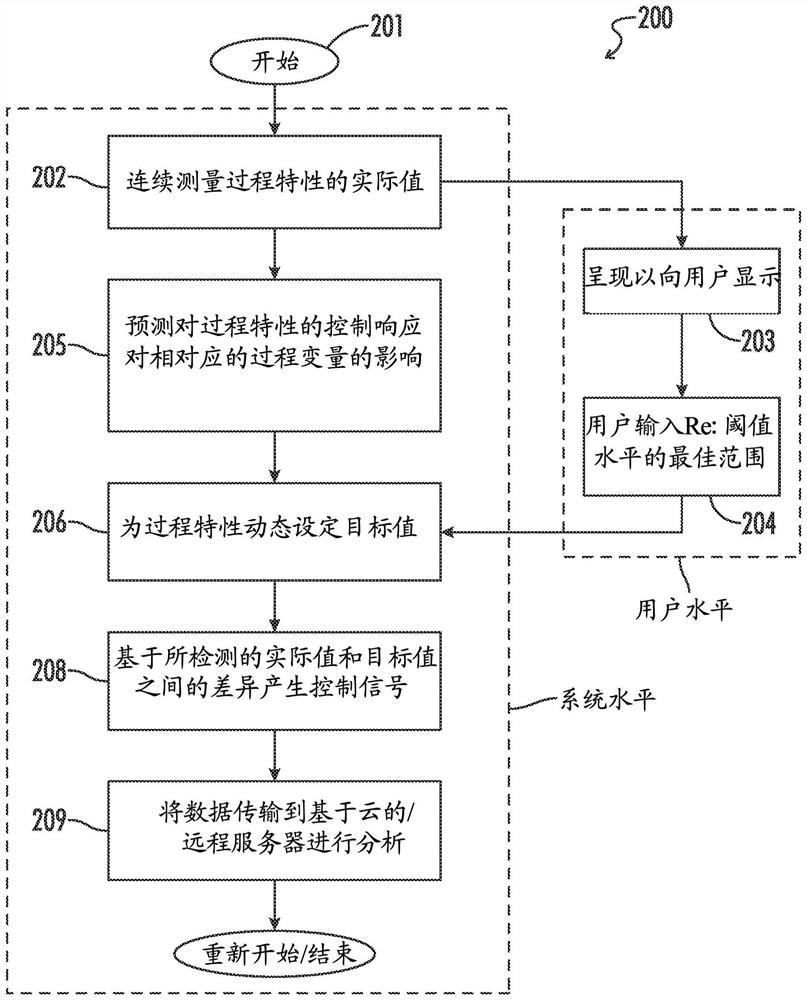

[0026] While the making and using of various embodiments of the present invention are discussed in detail below, it should be appreciated that the present invention provides many applicable inventive concepts that can be embodied in a wide variety of specific contexts. The specific embodiments discussed herein are merely illustrative of specific ways to make and use the invention, and do not delineate the scope of the invention.

[0027] The following detailed description of embodiments of the present disclosure refers to one or more accompanying drawings. The figures are provided for the purpose of explaining the present disclosure and are not limiting. Those skilled in the art will appreciate that various modifications and variations can be made in the teachings of the present disclosure without departing from the scope of the present disclosure. For example, features shown or described as part of one embodiment can be used with another embodiment to yield yet another embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com