Method for improving integrating degree of surface oxide layer and application

A technology of oxide layer and fit, which is applied in the field of solar cells, can solve the problems of low fit between oxide layer and silicon base layer, affecting the chemical performance and anti-induction performance of solar cells, so as to increase fit, reduce surface recombination, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

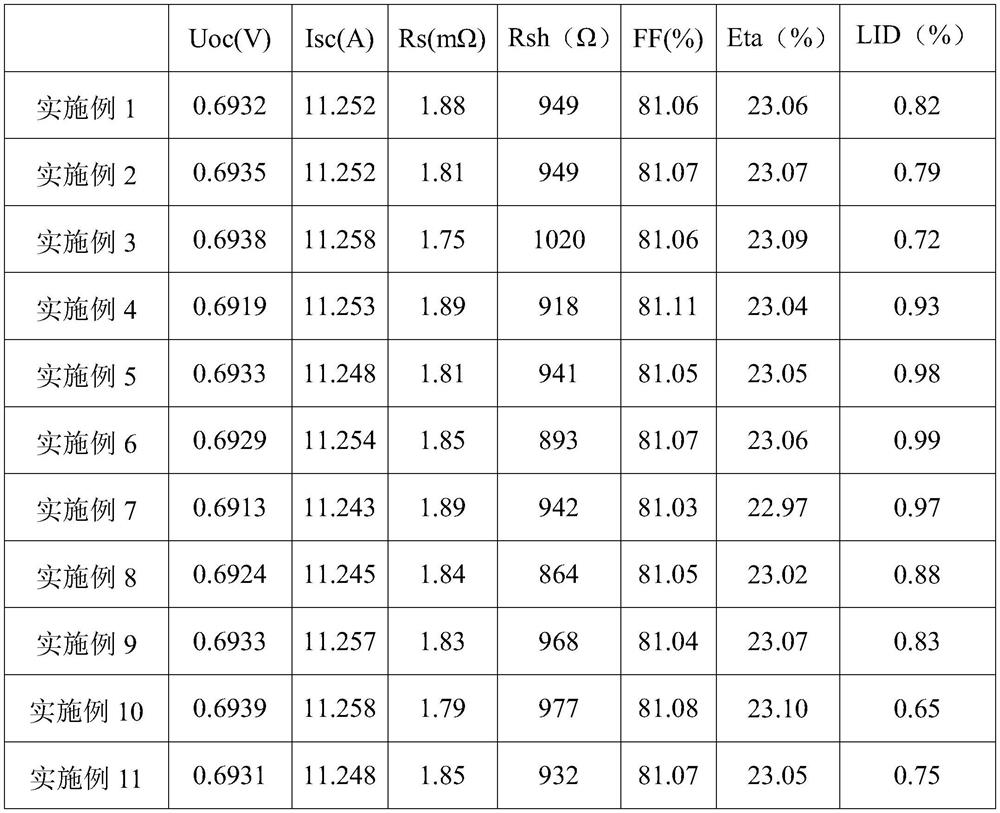

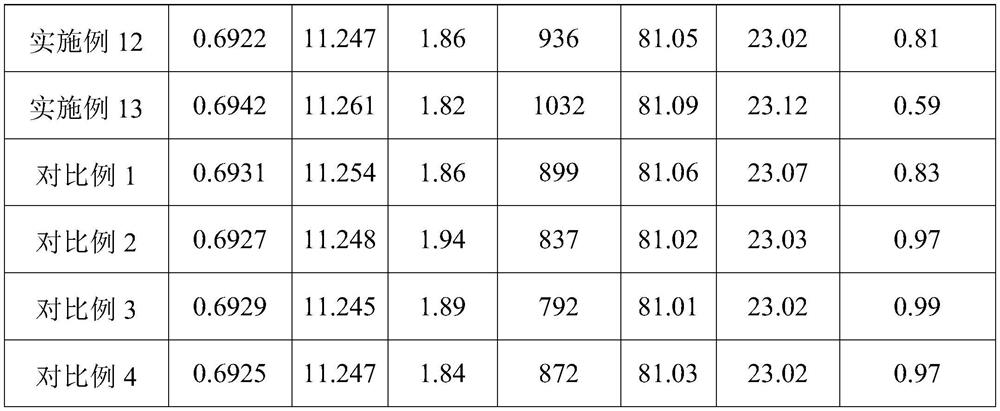

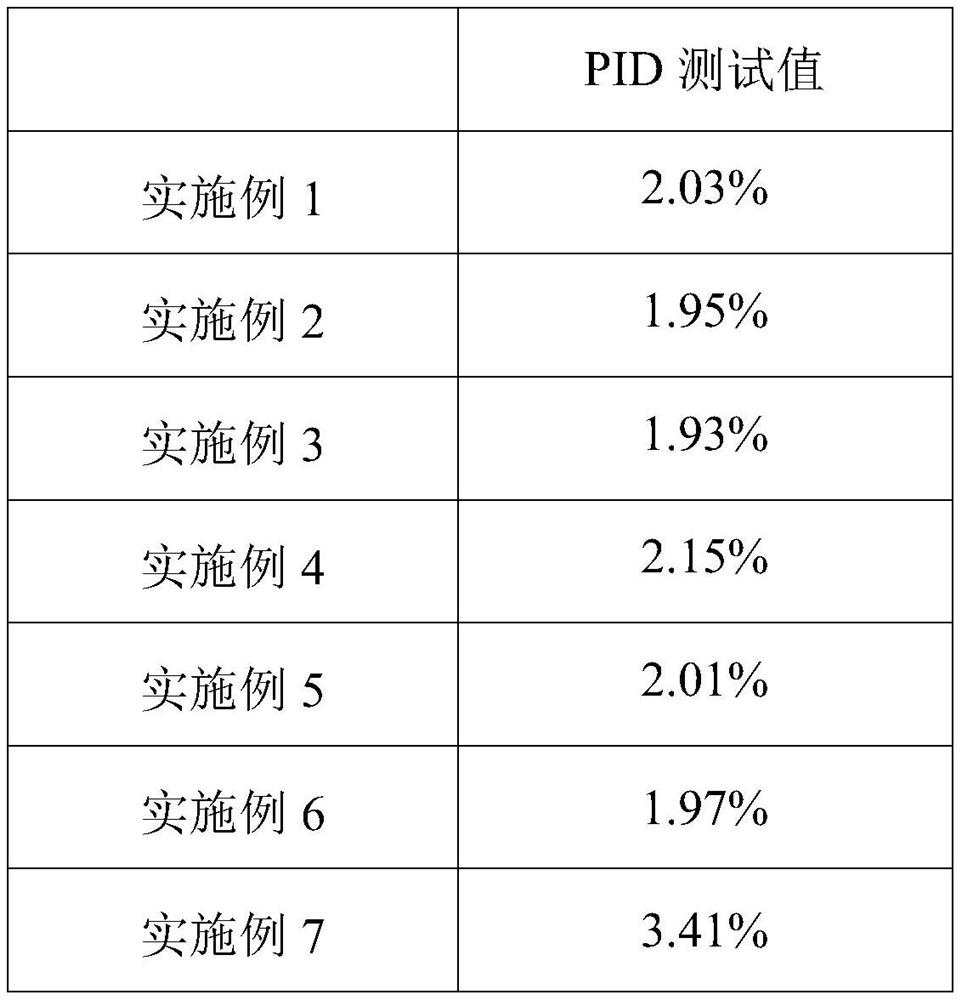

Examples

Embodiment 1

[0053] The present embodiment provides a method for improving the degree of fit of the surface oxide layer, and the process of the method is as follows:

[0054](1) Entering the boat: the temperature is 1000℃, the nitrogen flow is 15000sccm, the pressure is 1060Pa, and the time is 700s;

[0055] (2) Heating up: the temperature is 900°C, the nitrogen flow is 15000sccm, the pressure is 1060Pa, and the time is 500s;

[0056] (3) Vacuuming: the temperature is 900°C, the pressure is 0Pa, and the time is 200s;

[0057] (4) Catalytic purification: temperature 900℃, pressure 300Pa, dichloroethane 500sccm, dichlorosilane 1000sccm, nitrous oxide 2000sccm, time 1200s;

[0058] (5) Vacuuming: the temperature is 900°C, the pressure is 0Pa, and the time is 200s;

[0059] (6) Back pressure: the temperature is 900℃, the nitrogen flow is 15000sccm, the pressure is 1060Pa, and the time is 90s;

[0060] (7) Cooling and leaving the boat: 600°C, nitrogen flow for 15000sccm, pressure 1060Pa, tim...

Embodiment 2

[0062] This embodiment provides a method for improving the degree of fit of the surface oxide layer, and the process of the method is as follows:

[0063] (1) Entering the boat: the temperature is 1000℃, the nitrogen flow is 15000sccm, the pressure is 1060Pa, and the time is 700s;

[0064] (2) Heating up: the temperature is 900°C, the nitrogen flow is 15000sccm, the pressure is 1060Pa, and the time is 500s;

[0065] (3) Vacuuming: the temperature is 900°C, the pressure is 0Pa, and the time is 200s;

[0066] (4) Catalytic purification: temperature 900 ℃, pressure 300Pa, dichloroethane 1000sccm, dichlorosilane 1000sccm, nitrous oxide 2000sccm, time 1200s;

[0067] (5) Vacuuming: the temperature is 900°C, the pressure is 0Pa, and the time is 200s;

[0068] (6) Back pressure: the temperature is 900℃, the nitrogen flow is 15000sccm, the pressure is 1060Pa, and the time is 90s;

[0069] (7) Cooling and leaving the boat: 600°C, nitrogen flow for 15000sccm, pressure 1060Pa, time 80...

Embodiment 3

[0071] The difference between this example and Example 1 is only that the ventilation rate of dichloroethane in the catalytic purification described in step (4) is 2000sccm, and other conditions and parameters are exactly the same as those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com