Illuminating system suitable for proximity contact type automatic exposure machine

An automatic exposure and lighting system technology, which is applied in the field of lighting systems, can solve problems such as inconsistent wafer imaging effects, automatic alignment failures, and misjudgment of wafer marks, so as to facilitate automatic alignment, improve imaging effects, The effect of improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

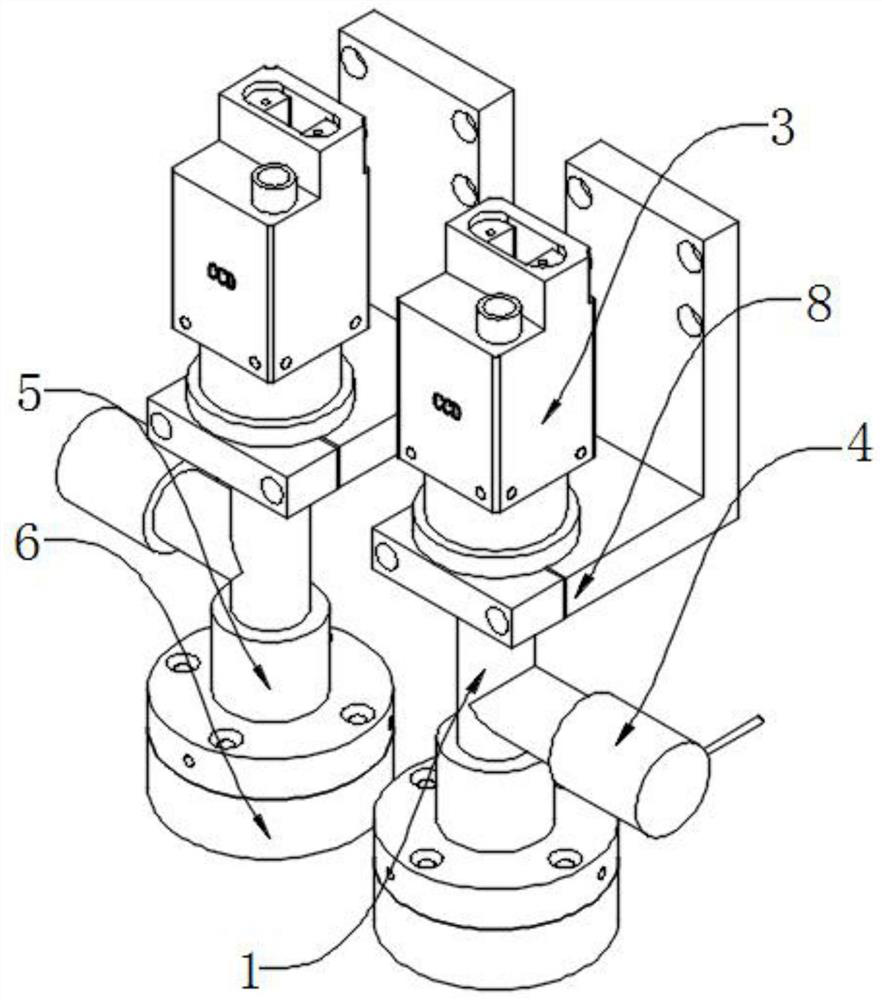

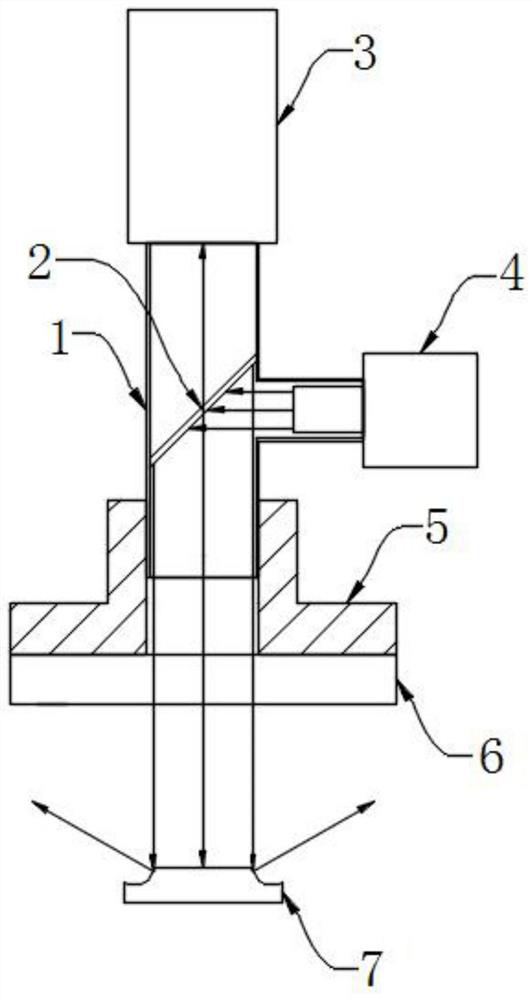

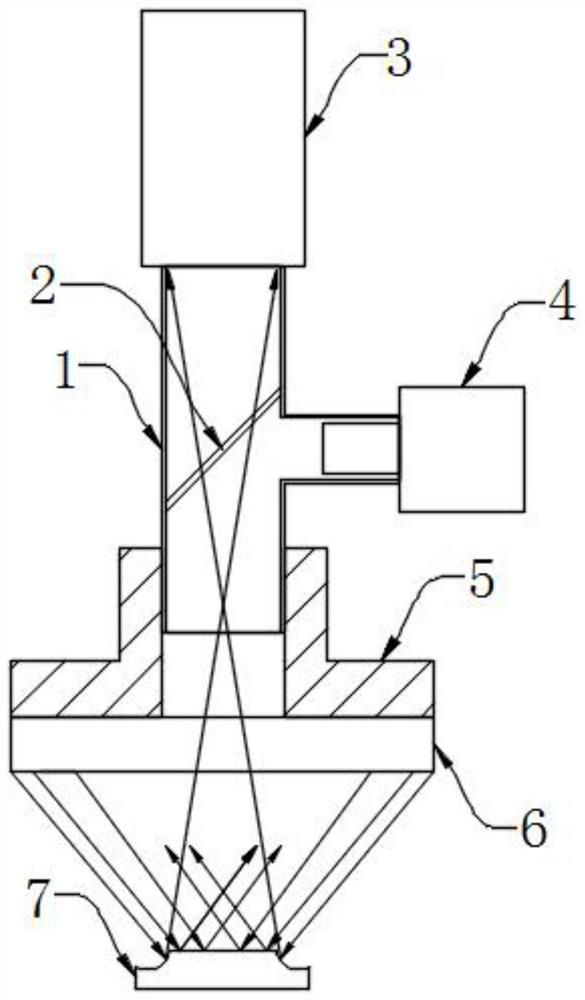

[0019] see Figure 1-3 , the present invention provides a technical solution: an illumination system suitable for a proximity contact type automatic exposure machine, comprising a lens 1, a half mirror 2 is installed on the inner wall of the lens 1, and a CCD camera is installed on the upper surface of the lens 1 3. A coaxial lighting lamp 4 is installed on the outer side wall of the lens 1, and an adjusting cylinder 5 is slidably connected to the outer side wall of the lens 1 and located below the coaxial lighting lamp 4, and the lower surface of the adjusting cylinder 5 is threadedly connected with a ring lighting lamp. 6.

[0020] In this embodiment, specifically, the adjusting cylinder 5 is arranged to slide vertically outside the lens 1, thereby driving the connected ring lighting 6 to perform height adjustment.

[0021] In this embodiment, specifically: an L-shaped connecting plate 8 is installed on the outer side wall of the lens 1 and located on the adjacent side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com