Flexible pipe for conveying oil gas and hydrogen and preparation method thereof

A flexible pipe and hydrogen technology, applied in the direction of chemical instruments and methods, pipes, hoses, etc., can solve the problems of glass fiber aging and brittleness, pipe strength attenuation, penetration, etc., to ensure stress bearing capacity, good strength and toughness, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

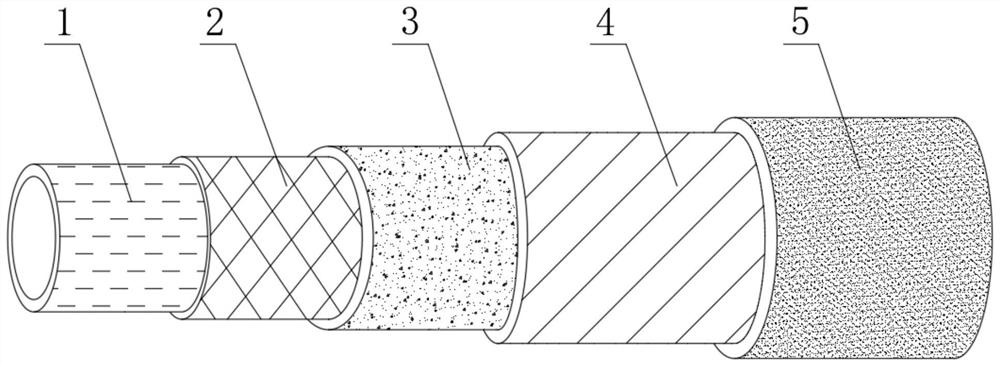

[0071] like figure 1 As shown in the figure, it is a flexible pipe for oil and gas and hydrogen transportation. The pipe is a five-layer composite structure. From the inside to the outside, it is an inner lining layer 1, a reinforcing layer 2, an inner protective layer 3, a weight layer 4 and an outer protective layer 5, including :

[0072] An inner liner 1, the inner liner 1 includes a first polymer;

[0073] Reinforcing layer 2, the reinforcing layer 2 includes a first metal filament;

[0074] an inner protective layer 3, the inner protective layer 3 includes a second polymer;

[0075] a weighted layer 4 comprising a second metal filament; and

[0076] Outer protective layer 5, the outer protective layer 5 includes a third polymer.

[0077] Wherein: the first polymer is selected from polyethylene.

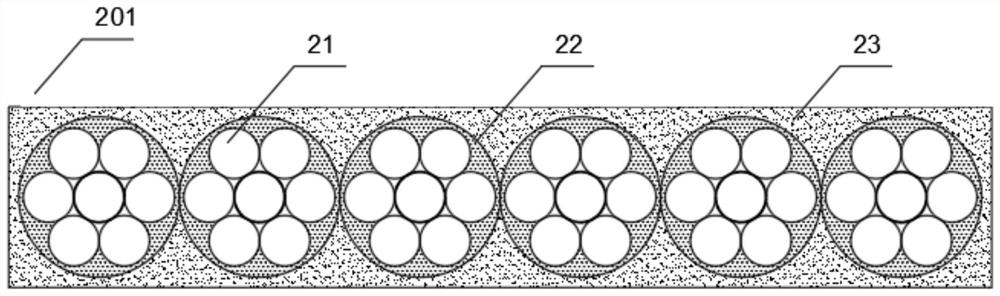

[0078] like figure 2 As shown, it is a resin-coated steel cord belt, and the first metal filament is selected from a double-layer resin-coated steel cord belt 201, compri...

Embodiment 2

[0095] The structure of the flexible pipe for oil and gas and hydrogen transportation is the same as the flexible pipe structure of Example 1, only the material selection of the first resin layer and the second resin layer of the inner lining layer and the resin-coated steel cord belt is changed, specifically: The first polymer is selected from cross-linked polyethylene; the first resin layer 22 is selected from polyvinylidene chloride; the second resin layer 23 is selected from cross-linked polyethylene;

[0096] The preparation method of the flexible pipe for oil and gas and hydrogen transportation comprises the following steps:

[0097] S1. Preparation of inner lining layer:

[0098] Add the material particles of the inner lining layer into the single-screw extruding hopper, heat the single-screw extruder, and extrude the material particles of the inner lining layer into the heating zone of the extruder. The heating zone is divided into 6 sections, and the temperature of ea...

Embodiment 3

[0108] The structure of the flexible pipe for oil and gas and hydrogen transportation is the same as the flexible pipe structure of Example 1, only the material selection of the first resin layer and the second resin layer of the inner lining layer and the resin-coated steel cord belt is changed, specifically: The first polymer is selected from polyvinylidene fluoride; the first resin layer 22 is selected from ethylene-vinyl alcohol copolymer; the second resin layer 23 is selected from polyvinylidene fluoride;

[0109] The preparation method of the flexible pipe for oil and gas and hydrogen transportation comprises the following steps:

[0110] S1. Preparation of inner lining layer:

[0111] Add the material particles of the inner lining layer into the single-screw extruding hopper, heat the single-screw extruder, and extrude the material particles of the inner lining layer into the heating zone of the extruder. The heating zone is divided into 6 sections, and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com