Composite pressure reduction type hydrogen energy pressure reducing valve

A pressure reducing valve, hydrogen energy technology, applied in the direction of functional valve type, lifting valve, balance valve, etc., can solve the problems such as the dynamic and stable adjustment ability needs to be improved, the damage of the hydrogen energy pressure reducing valve is large, and the pressure reduction effect needs to be improved. Achieve the effect of automatic adjustment, constant gas pressure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments.

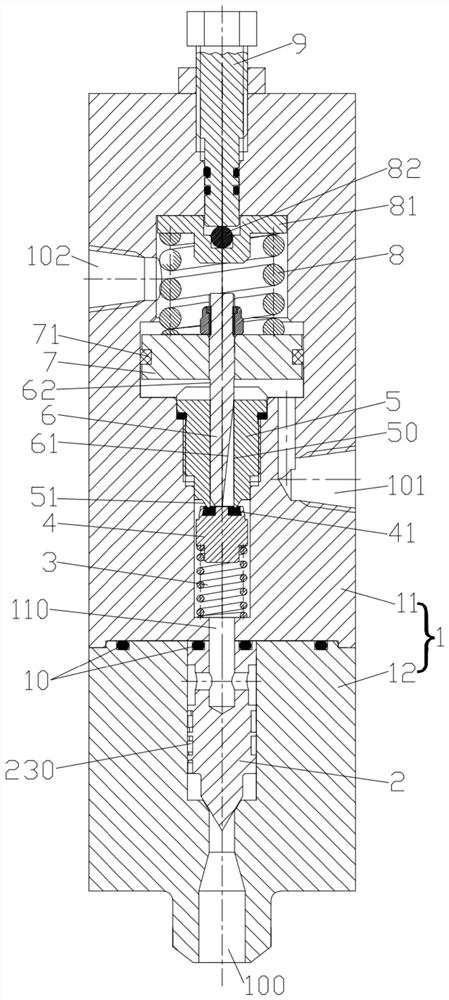

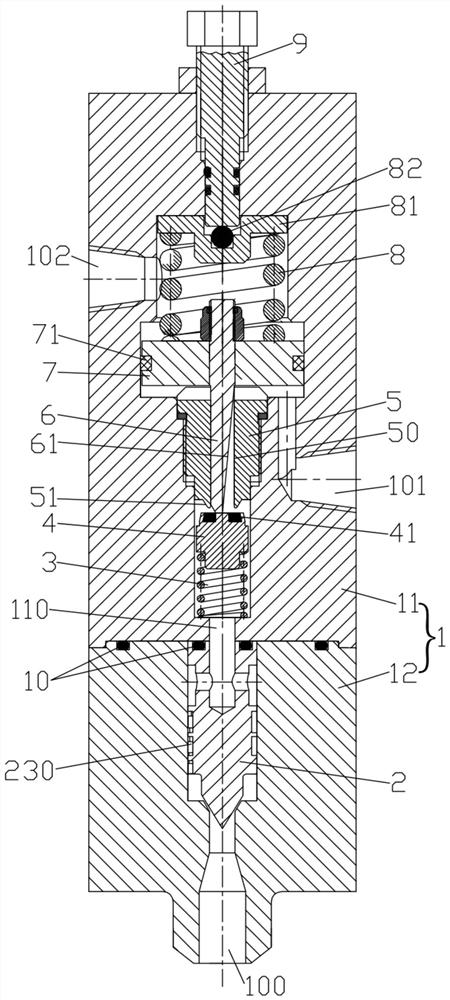

[0029] like figure 1 and 2 As shown in the figure, a compound pressure-reducing type hydrogen energy pressure reducing valve according to an embodiment of the present invention includes a valve body 1, the valve body 1 has a medium inlet 100 and a medium outlet 101, and a needle valve core is arranged at the medium inlet 100 2.

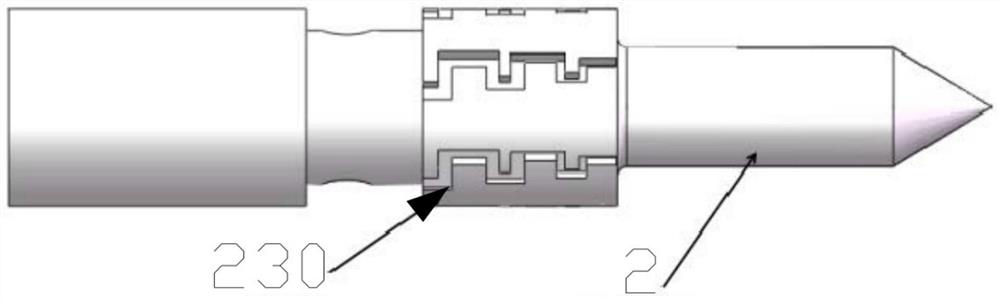

[0030] like image 3 and 4 As shown, the needle valve core 2 is a columnar structure, and the needle valve core 2 is divided into five sections according to the external dimensions, which are called the first section 21, the second section 22, the third section 23, and the fourth section 24 from bottom to top. and fifth paragraph 25. The first section 21 is the lower top of the needle valve core 2, which adopts a conical surface structure, and there is a gap between the conical surface structure and the valve body 1 for the medium to pass thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com