Bleaching process for animal fibers

An animal fiber and process technology, applied in the field of fiber bleaching, can solve the problems of reducing the economic benefit of bleaching, increasing the cost of the bleaching process, affecting the bleaching efficiency, etc., and achieving the effects of increasing the economic benefit, being less prone to over-bleaching, and increasing the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

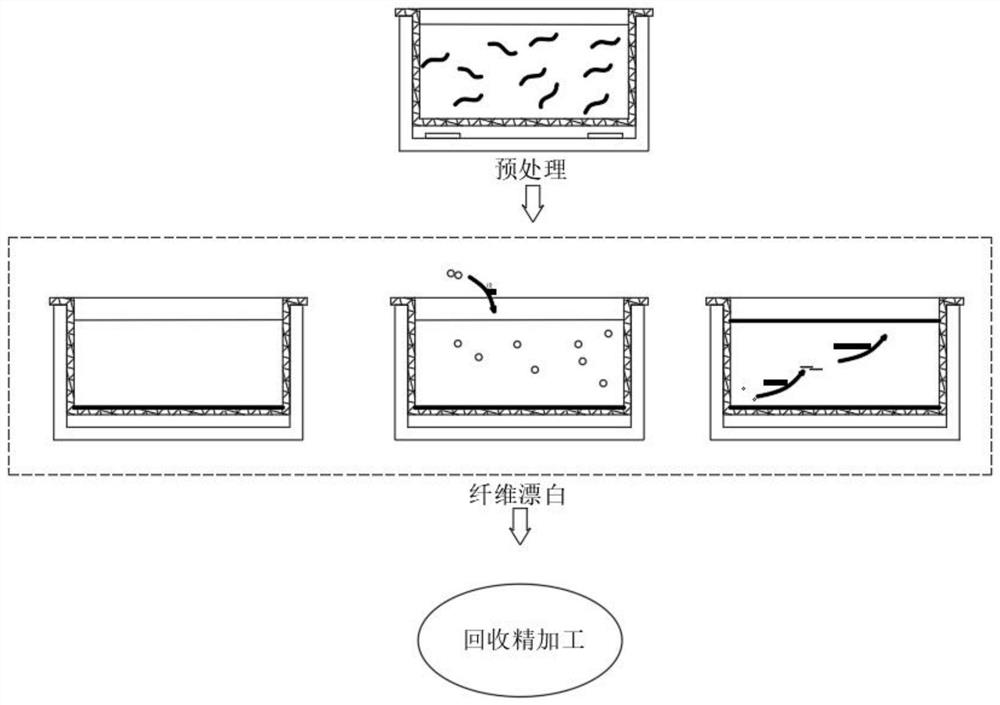

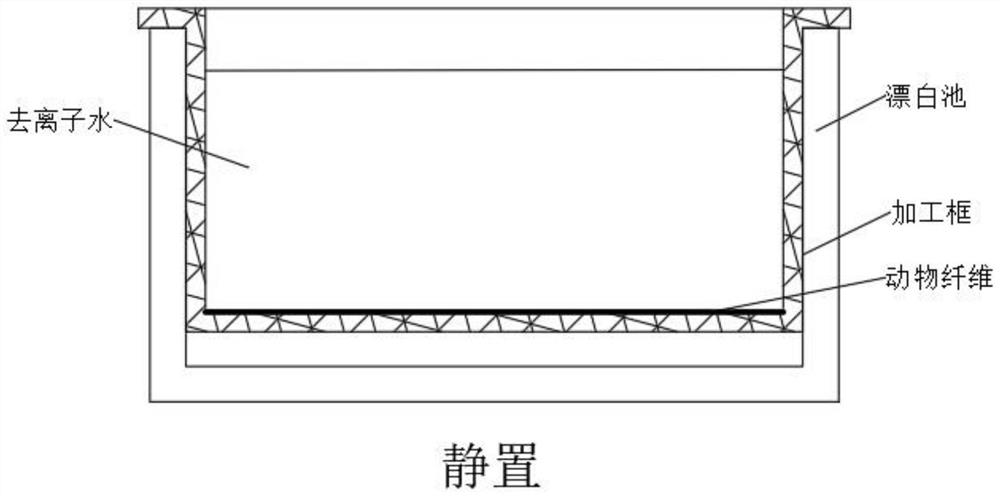

[0046] see Figure 1-9 , a bleaching process for animal fibers, which mainly includes the following steps:

[0047] S1, pretreatment, simply clean the animal fiber to be bleached, and put it into the pretreatment tank after clearing the sundries attached to the surface;

[0048] A sodium chloride solution is placed in the pretreatment tank, and its concentration is 20%. A processing frame matching itself is placed in the pretreatment tank. A plurality of animal fibers are located on the upper side of the processing frame, and the bottom plate of the pretreatment tank is placed on the bottom of the pretreatment tank. Several ultrasonic generating devices are fixedly connected, and the animal fibers are further cleaned by using the ultrasonic generating devices, and the small-diameter sundries attached are cleaned up, and then pass through the processing frame and fall into the bottom of the pretreatment tank. At the same time, under the action of ultrasonic waves The sodium ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com