Processing technology for preventing wool and down feather from being bonded after water washing

A processing technology and down technology, which is applied in the field of anti-bonding wool down processing technology after washing, can solve the problems of down filler sticking, affecting clothing warmth retention, loose and out of shape clothing, etc. loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

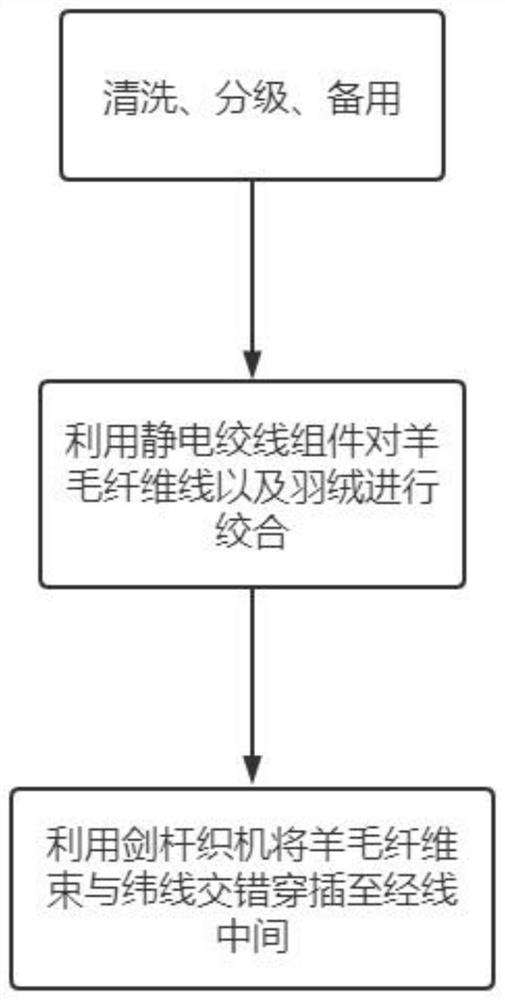

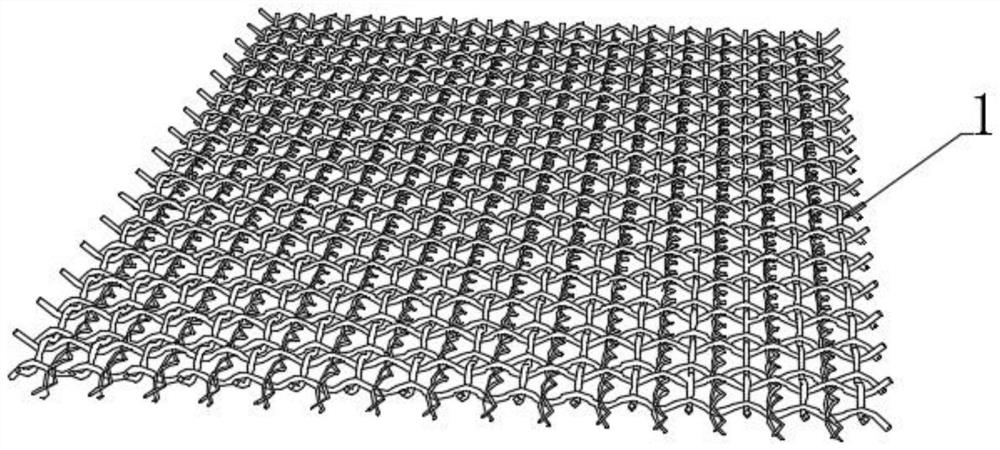

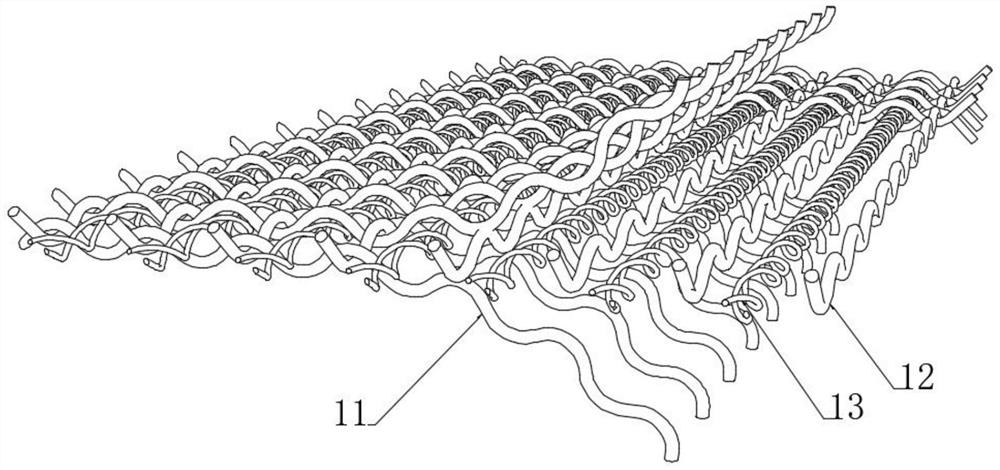

[0047] see Figure 1-4 , an anti-adhesion wool down processing technology after washing, including a woven inner bladder 1, the woven inner bladder 1 is woven from a plurality of crisscrossed warp threads 11 and weft threads 12, and the warp threads 11 and the weft threads 12 are made of wool fibers, Wool down bundles 13 are interspersed between two adjacent weft threads 12. The wool down bundles 13 include a plurality of wool fiber threads 131 intertwined with each other, and down among the multiple wool fiber threads 131. The processing technology of the woven inner bladder 1 includes the following: step:

[0048] S1. The workers firstly classify and select the down, immerse the different grades of down in the cleaning pool containing detergent respectively, wash them in an all-round way after stirring, then take out the down and dry it, and finally dry it. The remaining down is placed in the receiving box 5 for use. Cleaning the down can reduce the stains on the down and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com