Strong-acid-erosion-resistant high-entropy alloy coating for repairing stirring paddle blade of phosphoric acid reaction tank and preparation method of high-entropy alloy coating

A phosphoric acid reaction tank and high-entropy alloy technology, applied in the field of alloys, can solve problems such as variable structure and complex components of high-entropy alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

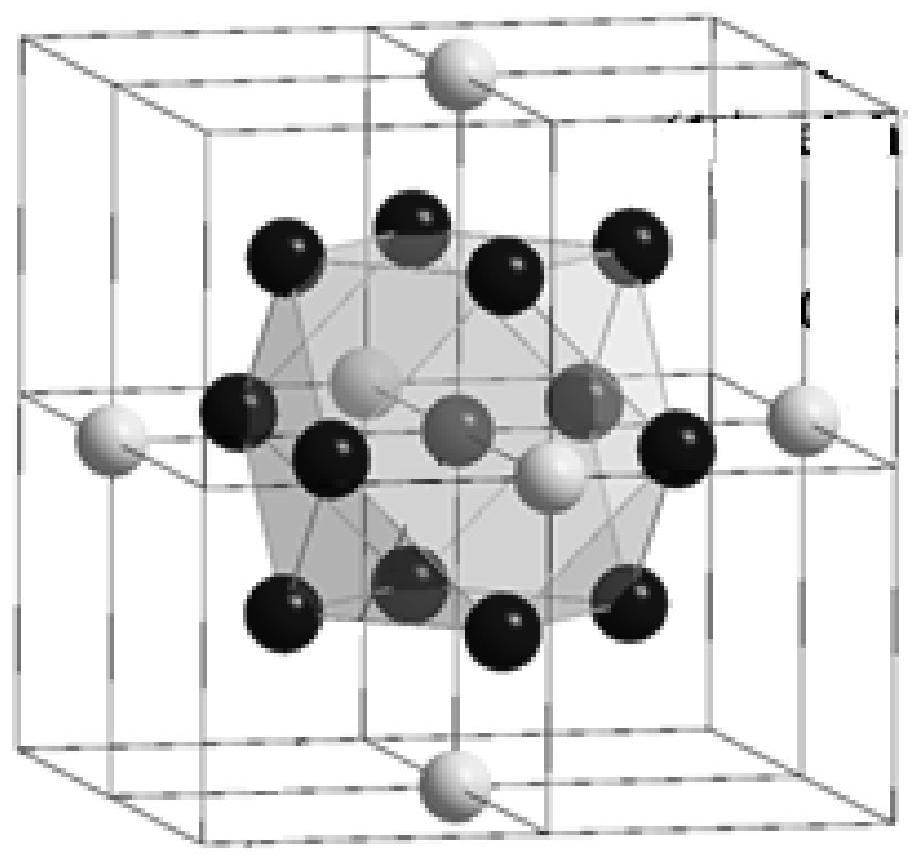

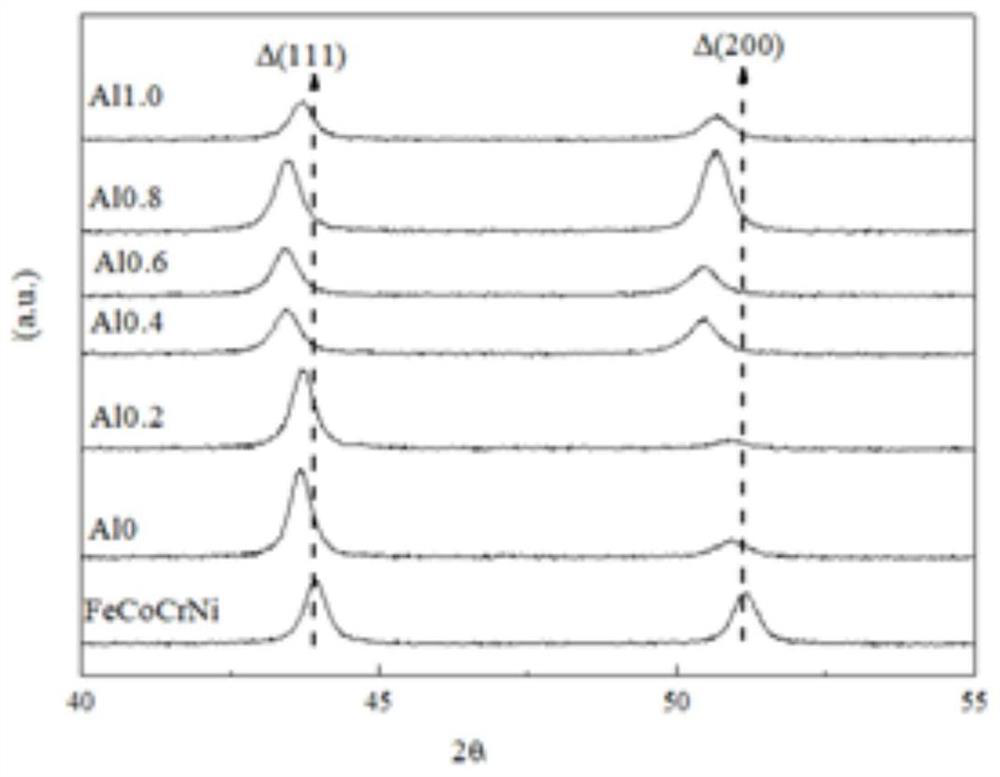

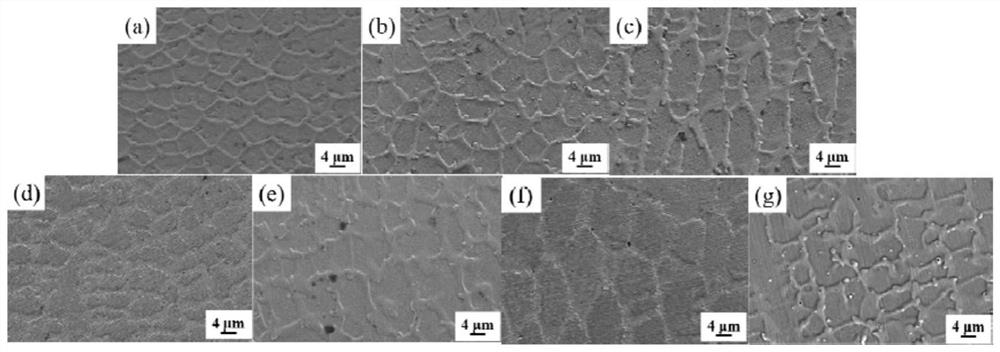

[0034] (1) Composition design: according to 904L stainless steel grade (00Cr 20 Ni 25 Mo 4.5 Cu), converted into the corresponding atomic ratio: Fe-24.2Ni-22.9Cr-2.6Mo-1.5Mn-1.3Cu, according to the cluster plus connecting atom model, its cluster formula can be described as [Cr-Fe 7.6 Ni 3.9 Mn 0.3 Cu 0.2 ]Cr 2.6 Mo 0.4 . Without considering Mn and Cu, the concept of "average atom" is introduced, and the group VIII Fe, Co, and Ni with similar atomic properties and weak interaction force are regarded as the average atom M, and M is selected as the solvent atom to replace Fe and Ni at the atomic positions of the shell, the cluster model we constructed from this is [Cr-Fe 4 Co 4 Ni 4 ]Cr 2.6 Mo 0.4 (Co 25 Cr 22.5 Fe 25 Ni 25 Mo 2.5 , at.%). On this basis, we plan to add Al atoms at the connecting atom positions to further construct the ordered phase coherent precipitation of [Cr-Fe 4 Co 4 Ni 4 ]Cr 2.6-x Al x Mo 0.4 A high-entropy alloy system is used to imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com