Solid-waste-based PVC (polyvinyl chloride) calendering film matrix high-temperature-resistant material and preparation method thereof

A calendered film and high-temperature-resistant technology, which is applied in the field of solid waste-based PVC calendered film substrate high-temperature-resistant materials and their preparation, can solve the problems of high price, lack of fiber characteristics, and large primary resource consumption, etc., to improve high-temperature resistance. Improvement of related performance and effect of weather resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

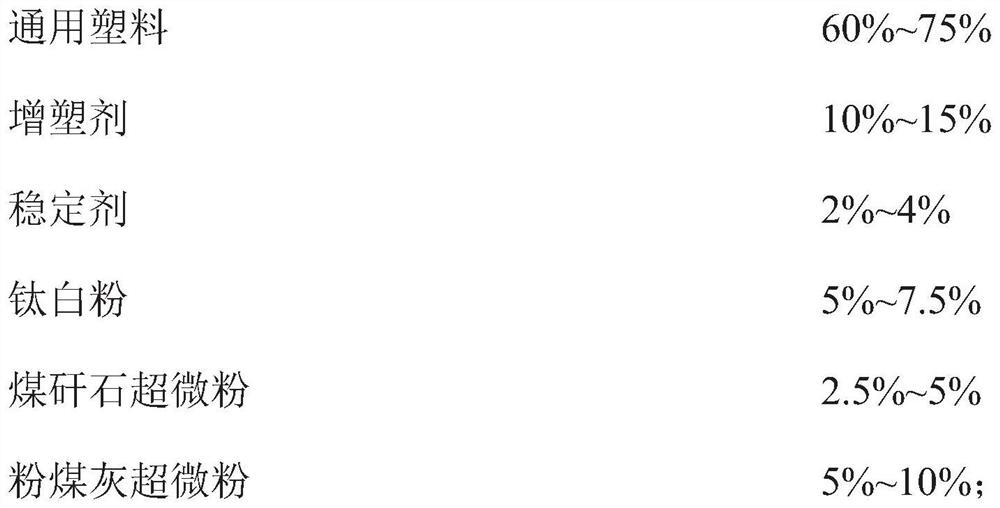

[0024] Taking the preparation of product 100g of the present invention as an example, the used component and its mass ratio are:

[0025]

[0026]

[0027] The general plastic is polyvinyl chloride.

[0028] The plasticizer is dioctyl phthalate.

[0029] The stabilizer is CT303TX liquid calcium zinc stabilizer.

[0030] The particle size of the titanium dioxide is 1.0 μm, and the rutile TiO 2 The mass content is 98%, the oil absorption is 20g / 100g, and the pH of the aqueous suspension is 9.

[0031] The coal gangue ultrafine powder is the coal gangue that is ground to 2500 mesh coal gangue ultrafine powder by the ultrafine tire vertical mill (also known as "ultrafine roller grinding"). The main chemical composition of the coal gangue: SiO 2 54.5%, Al 2 O 3 30.6%, Fe 2 O 3 5.63%, CaO 1.32%, MgO 1.41%, TiO 2 is 1.96%, K 2 O is 1.45%, Na 2 O was 0.39%, and the others were 2.74%.

[0032] The fly ash ultrafine powder is the fly ash that is ground to 2000 mesh by t...

Embodiment 2

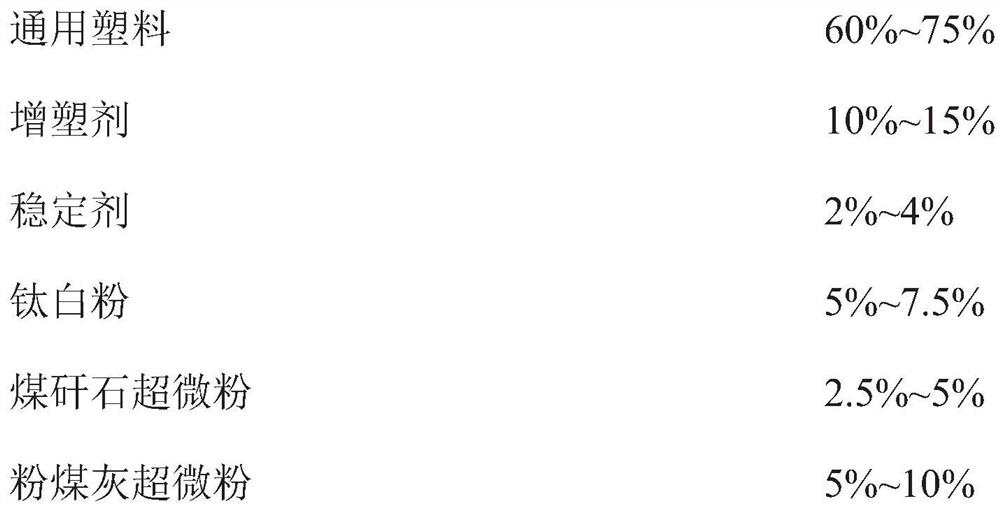

[0035] Taking the preparation of product 100g of the present invention as an example, the used component and its mass ratio are:

[0036]

[0037] The general plastic is polyvinyl chloride.

[0038] The plasticizer is dioctyl phthalate.

[0039] The stabilizer is CT303TX liquid calcium zinc stabilizer.

[0040] The particle size of the titanium dioxide is 1.0 μm, and the rutile TiO 2 The mass content is 98%, the oil absorption is 20g / 100g, and the pH of the aqueous suspension is 6.

[0041] The coal gangue ultrafine powder is the coal gangue that is ground to 2500 mesh coal gangue ultrafine powder by the ultrafine tire vertical mill (also known as "ultrafine roller grinding"). The main chemical composition of the coal gangue: SiO 2 54.5%, Al 2 O 3 30.6%, Fe 2 O 3 5.63%, CaO 1.32%, MgO 1.41%, TiO 2 is 1.96%, K 2 O is 1.45%, Na 2 O was 0.39%, and the others were 2.74%.

[0042] The fly ash ultrafine powder is the fly ash that is ground to 2000 mesh by the ultrafine...

Embodiment 3

[0045] Taking the preparation of product 100g of the present invention as an example, the used component and its mass ratio are:

[0046]

[0047] The general plastic is polyvinyl chloride.

[0048] The plasticizer is dioctyl phthalate.

[0049] The stabilizer is CT303TX liquid calcium zinc stabilizer.

[0050] The particle size of the titanium dioxide is 1.0 μm, and the rutile TiO 2 The mass content is 98%, the oil absorption is 20g / 100g, and the pH of the aqueous suspension is 8.

[0051] The coal gangue ultrafine powder is the coal gangue that is ground to 2500 mesh coal gangue ultrafine powder by the ultrafine tire vertical mill (also known as "ultrafine roller grinding"). The main chemical composition of the coal gangue: SiO 2 54.5%, Al 2 O 3 30.6%, Fe 2 O 3 5.63%, CaO 1.32%, MgO 1.41%, TiO 2 is 1.96%, K 2 O is 1.45%, Na 2 O was 0.39%, and the others were 2.74%.

[0052] The fly ash ultrafine powder is the fly ash that is ground to 2000 mesh by the ultrafine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com