Desulfurized ash/PVC calendering film base material and preparation method thereof

A technology of matrix material and calendered film, which is applied in the field of desulfurization ash/PVC calendered film matrix material and its preparation, can solve the problems of reducing material rigidity and strength, not having fiber characteristics, and large resource consumption at one time, so as to improve compatibility , Improve the inorganic properties, improve the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

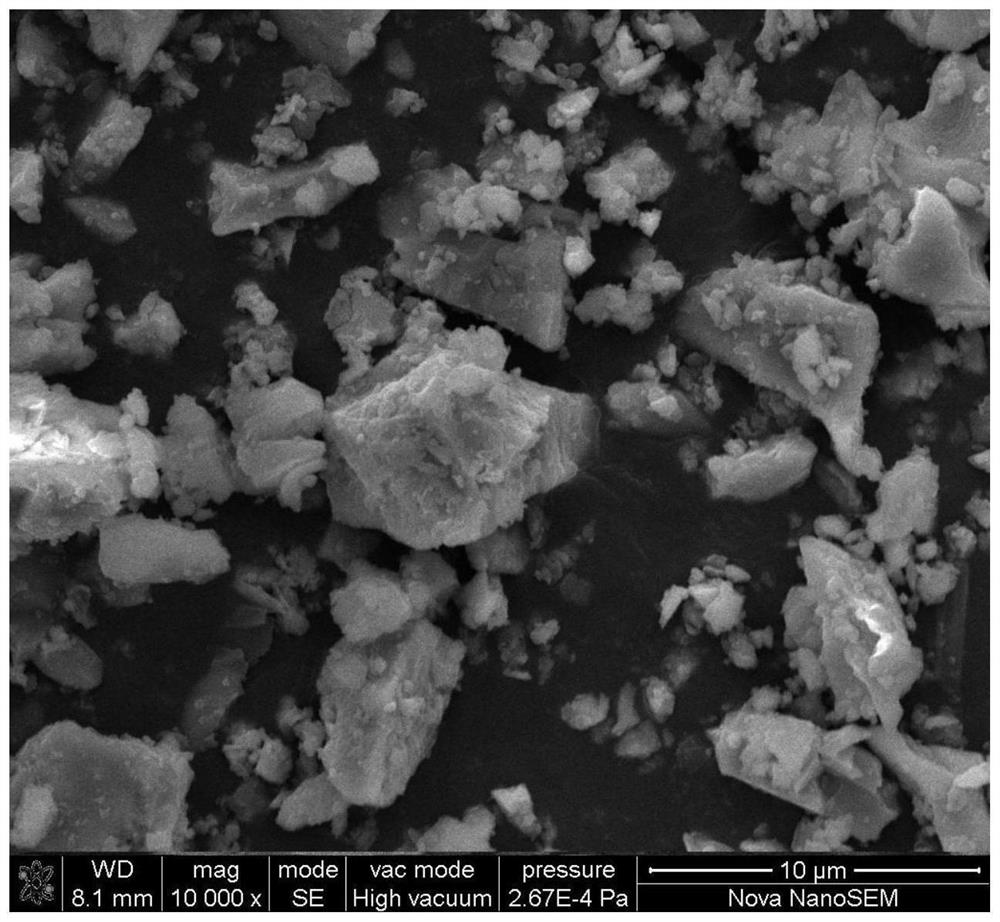

Image

Examples

Embodiment 1

[0028] Taking the preparation of product 100g of the present invention as an example, the used component and its mass ratio are:

[0029]

[0030] The general plastic is polyvinyl chloride (PVC).

[0031] The elastic composite is a mixture of nitrile rubber and recycled rubber, and its mass ratio is 10:2.

[0032] The plasticizer is dinonyl phthalate.

[0033] The stabilizer is SX-105 heat stabilizer.

[0034] The desulfurized ash ultrafine powder is semi-dry desulfurized ash that is ground to 1750 mesh semi-dry desulfurized ash ultrafine powder by an ultrafine tire vertical mill (also known as "ultrafine roller mill"). The chemical composition of semi-dry desulfurization is CaO (73.49%), SO 3 (15.02%), Cl (4.91%), Na 2 O(2.63%), SiO 2 (0.57%), K 2 O (0.92%), Al 2 O 3 (0.52%), MgO (0.35%), Fe 2 O 3 (0.22%), others (1.37%).

[0035] The surface modifier is a mixture of phosphoric acid, coupling agent KH550 and absolute ethanol, and its mass ratio is 1:5:10.

[00...

Embodiment 2

[0040] Taking the preparation of product 100g of the present invention as an example, the used component and its mass ratio are:

[0041]

[0042] The general plastic is polyvinyl chloride (PVC).

[0043] The elastic composite is a mixture of nitrile rubber and recycled rubber, and its mass ratio is 10:3.

[0044] The plasticizer is dinonyl phthalate.

[0045] The stabilizer is SX-105 heat stabilizer.

[0046] The desulfurized ash ultrafine powder is a semi-dry desulfurized ash ultrafine powder that is ground to a 1250 mesh semi-dry desulfurized ash ultrafine powder by an ultra-fine tire vertical mill (also known as "ultra-fine roller mill"). The chemical composition of semi-dry desulfurization is CaO (73.49%), SO 3 (15.02%), Cl (4.91%), Na 2 O(2.63%), SiO 2 (0.57%), K 2 O (0.92%), Al 2 O 3 (0.52%), MgO (0.35%), Fe 2 O 3 (0.22%), others (1.37%).

[0047] The surface modifier is a mixture of phosphoric acid, coupling agent KH550 and absolute ethanol, and the mass ...

Embodiment 3

[0052] Taking the preparation of product 100g of the present invention as an example, the used component and its mass ratio are:

[0053]

[0054] The general plastic is polyvinyl chloride (PVC).

[0055] The elastic composite is a mixture of nitrile rubber and recycled rubber, and its mass ratio is 10:1.

[0056] The plasticizer is dinonyl phthalate.

[0057] The stabilizer is SX-105 heat stabilizer.

[0058] The desulfurized ash ultrafine powder is a semi-dry desulfurized ash ultrafine powder that is ground to a 2500 mesh semi-dry desulfurized ash ultrafine by an ultra-fine tire vertical mill (also known as "ultra-fine roller mill"). The chemical composition of semi-dry desulfurization is CaO (73.49%), SO 3 (15.02%), Cl (4.91%), Na 2 O(2.63%), SiO 2 (0.57%), K 2 O (0.92%), Al 2 O 3 (0.52%), MgO (0.35%), Fe 2 O 3 (0.22%), others (1.37%).

[0059] The surface modifier is a mixture of phosphoric acid, coupling agent KH550 and absolute ethanol, and its mass ratio i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com