Glucose glycosylation rice bran protein-chitosan functional composite membrane and preparation method thereof

A rice bran protein and glucose technology, which is applied in the field of glucose glycosylated rice bran protein-chitosan functional composite membrane and its preparation field, and achieves the effects of improving solubility and sulfhydryl content, being economical, and improving application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

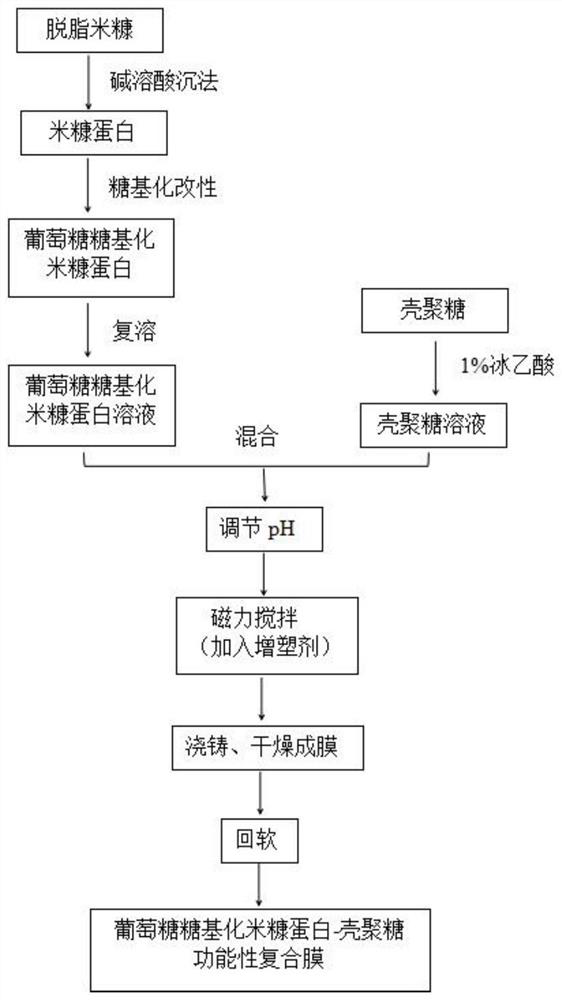

Method used

Image

Examples

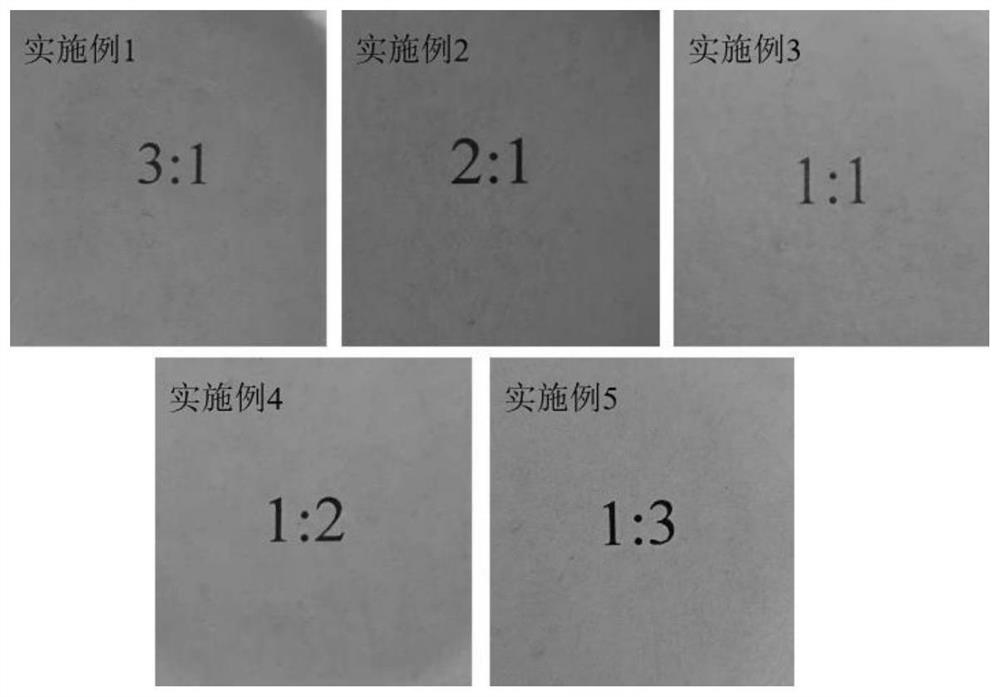

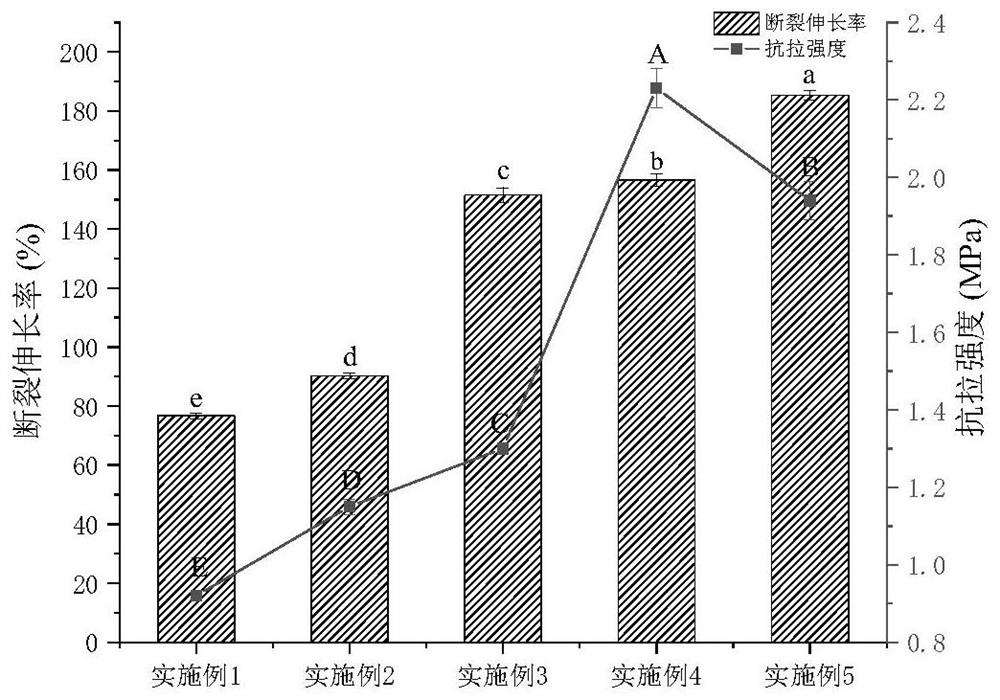

Embodiment 1

[0033] A preparation method of a glucose glycosylated rice bran protein-chitosan functional composite membrane, the specific steps are as follows:

[0034] 1) Extract rice bran protein from defatted rice bran by alkali-soluble acid precipitation method: mix defatted rice bran and distilled water at a ratio of 1:9 to liquid, adjust the pH of the mixture to 9.5 with 1 mol / L NaOH, and stir at 50°C for 2 hours. After the rice bran residue was removed by filtration, the filtrate was centrifuged at 6000 r / min for 15 min, and the pH of the centrifuged supernatant was adjusted to 4.5 with 1 mol / L HCl. 1:5 dilution, adjust pH to 7.0, freeze-dry at -55°C and 0.5mbar for 48h to obtain rice bran protein;

[0035] 2) Glucose glycosylation-modified rice bran protein: take 3 g of the rice bran protein obtained in step 1), dissolve it in 100 mL, pH 9, 50 mmol / L phosphate buffer solution, add 3 g of glucose, stir evenly, and then adjust the pH to 9.0 , stirred in a water bath at 85°C for 90mi...

Embodiment 2

[0040] A preparation method of a glucose glycosylated rice bran protein-chitosan functional composite membrane, the specific steps are as follows:

[0041] 1) Extract rice bran protein from defatted rice bran by alkali-soluble acid precipitation method: mix defatted rice bran and distilled water with a material-to-liquid ratio of 1:9, use 1 mol / L NaOH to adjust the pH of the mixture to 9.5, and stir at 50 °C for 2 hours. After the rice bran residue was removed by filtration, the filtrate was centrifuged at 6000r / min for 15min, and the supernatant after centrifugation was adjusted to pH 4.5 with 1mol / L HCl. After centrifugation at 6000r / min for 15min again, the precipitate was collected, and the precipitate was mixed with distilled water in a solid-liquid ratio. 1:5 dilution, adjust pH to 7.0, freeze-dry at -50°C and 0.45mbar for 48h to obtain rice bran protein;

[0042] 2) Glucose glycosylation-modified rice bran protein: take 3 g of the rice bran protein obtained in step 1), ...

Embodiment 3

[0047] A preparation method of a glucose glycosylated rice bran protein-chitosan functional composite membrane, the specific steps are as follows:

[0048] 1) Extract rice bran protein from defatted rice bran by alkali-soluble acid precipitation method: mix defatted rice bran and distilled water with a material-to-liquid ratio of 1:9, use 1 mol / L NaOH to adjust the pH of the mixture to 9.5, and stir at 50 °C for 2 hours. After the rice bran residue was removed by filtration, the filtrate was centrifuged at 6000r / min for 15min, and the supernatant after centrifugation was adjusted to pH 4.5 with 1mol / L HCl. After centrifugation at 6000r / min for 15min again, the precipitate was collected, and the precipitate was mixed with distilled water in a solid-liquid ratio. 1:5 dilution, adjust pH to 7.0, freeze-dry at -50°C and 0.43mbar for 48h to obtain rice bran protein;

[0049] 2) Glucose glycosylation-modified rice bran protein: take 3 g of the rice bran protein obtained in step 1), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com