Temperature-resistant dihydroxyl cationic viscoelastic surfactant, preparation method thereof, fracturing fluid and application of temperature-resistant dihydroxyl cationic viscoelastic surfactant

A technology of surfactant and dihydroxy cation, which is applied in the fields of high-temperature fracturing fluid, surfactant, and hot dry rock stimulation, can solve problems such as insufficient temperature and limited temperature resistance of VES clean fracturing fluid, and achieve high durability High temperature capability, excellent viscoelasticity and shear resistance, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Synthesis of temperature-resistant dihydroxy cationic viscoelastic surfactant

[0041] The preparation method of the present embodiment is as follows:

[0042]In the solution of 2-phenylbenzoic hydrazide and epichlorohydrin in ethanol, add the amount in a molar ratio of 1:1.2, and add HCl in the same molar ratio as epichlorohydrin at the same time, and react at 80 ° C for 10 hours , and finally, ethanol, excess epichlorohydrin and HCl were removed by rotary evaporation to obtain an intermediate.

[0043] The surfactant is to dissolve the erucamidopropyl dimethylamine and the intermediate in an ethanol solution with a molar ratio of 1:1, heating the temperature to 80 ° C, and reacting for 12 hours to obtain a temperature-resistant bishydroxy cationic viscoelastic surfactant. crude product. The above-mentioned preparation process also includes its proposed process: dissolving the crude product with ethyl acetate at 50° C., and then recrystallizing the crude pr...

Embodiment 2

[0044] Example 2 Preparation of fracturing fluid

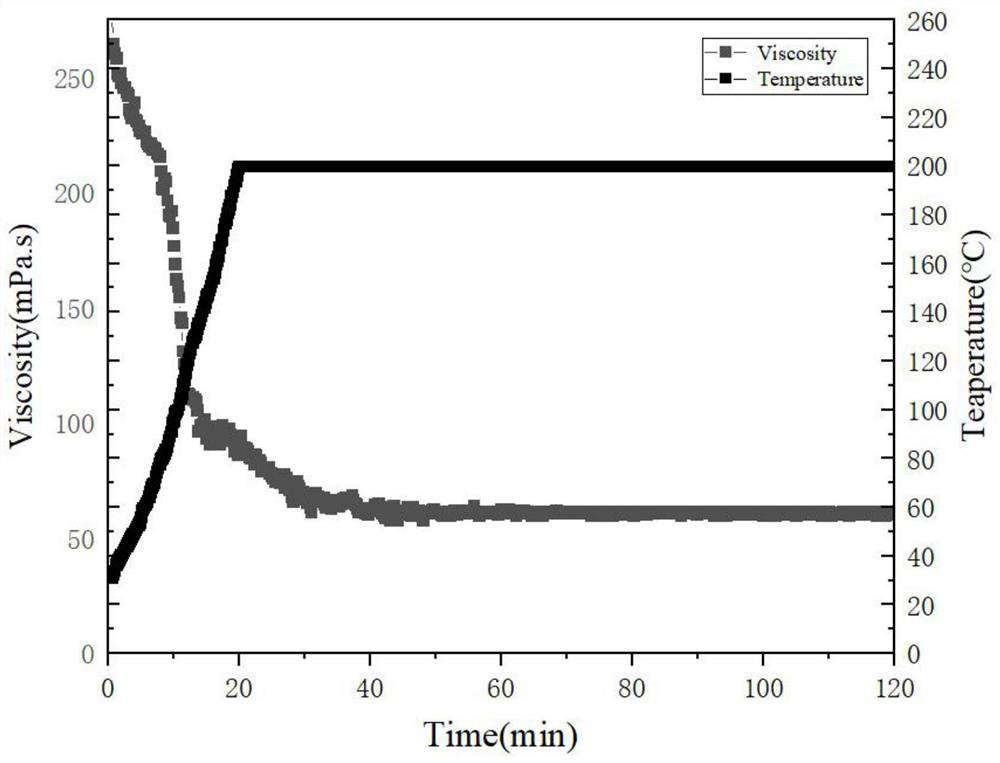

[0045] Take the viscoelastic surfactant in Example 1, configure fracturing fluid according to the water injection quality standard for hot dry rock development in a certain place in Qinghai, add 4.3% viscoelastic surfactant, and the remaining consumption is water (see Table 1 for specific water quality) , configured as a temperature-resistant and fast-dissolving clean fracturing fluid and tested its rheological properties, the results are as follows figure 1 shown, at 200°C, 170s -1 Under 2 hours of shearing, the apparent viscosity remains above 30mPa·s, which meets the requirements of the industry standard SY / T6376-2008.

Embodiment 3

[0046] Example 3 Preparation of fracturing fluid

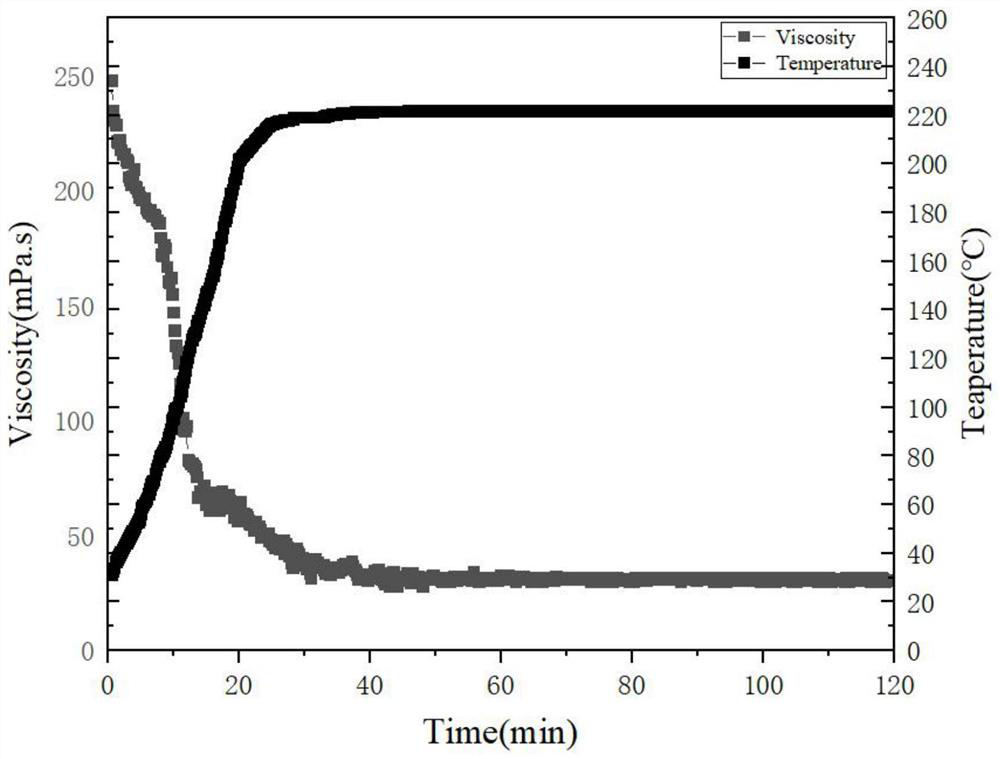

[0047] Take the viscoelastic surfactant in Example 1, configure fracturing fluid according to the water injection quality standard for hot dry rock development in a certain place in Qinghai, add 4.3% viscoelastic surfactant, and the remaining consumption is water (see Table 1 for specific water quality) , configured as a temperature-resistant clean fracturing fluid and tested its rheological properties, the results are as follows figure 2 shown, at 220°C, 170s -1 Under 2 hours of shearing, the apparent viscosity remains above 30mPa·s, which meets the requirements of the industry standard SY / T6376-2008.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com