Etringite-based energy storage foam light soil as well as preparation method and application thereof

A foam lightweight soil and ettringite-based technology, applied in applications, other household appliances, ceramic products, etc., can solve problems such as road surface structure and durability damage, easy traffic safety, and road surface permanent damage, and achieve improvement Effects of durability, material cost reduction, and enhancement of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

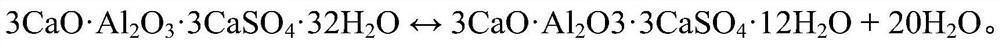

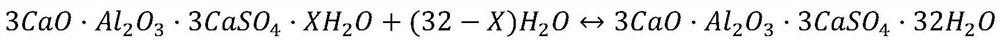

Method used

Image

Examples

Embodiment 1

[0047] 1) Preparation of cement slurry

[0048] The high ettringite content material was produced with a mixture of ordinary Portland cement (20 wt%) (designated C80P20) and premixed calcium aluminate cement (80 wt%) containing anhydrite. The cementitious mixture was hydrated with demineralized water at a ratio of water to cementitious mixture of 1.1. The cement mixture, gypsum and water were added in a mixer to prepare cement slurry, and the mixing molar ratio of cement and gypsum was controlled to be 2. Before mixing, the two materials should be fully mixed to ensure full contact during hydration. In order to avoid the conversion of ettringite to monosulfur-type hydrated calcium sulfoaluminate with the hydration of tricalcium aluminate in the later stage, water should be added first and then the mixture of Portland cement and gypsum should be added during mixing, and the cement slurry should be fully stirred. Set aside after mixing well.

[0049] 3) Preparation of foam cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com