Automatic double-row hole drilling, shaping and hoop pressing all-in-one machine for irrigation pipe of pointer type sprinkling machine

A technology of double rows of holes and irrigation pipes, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low straightness of outlet holes, easy occurrence of irrigation pipes, and low degree of automation, and achieve high drilling efficiency and automation The effect of high degree and high drilling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

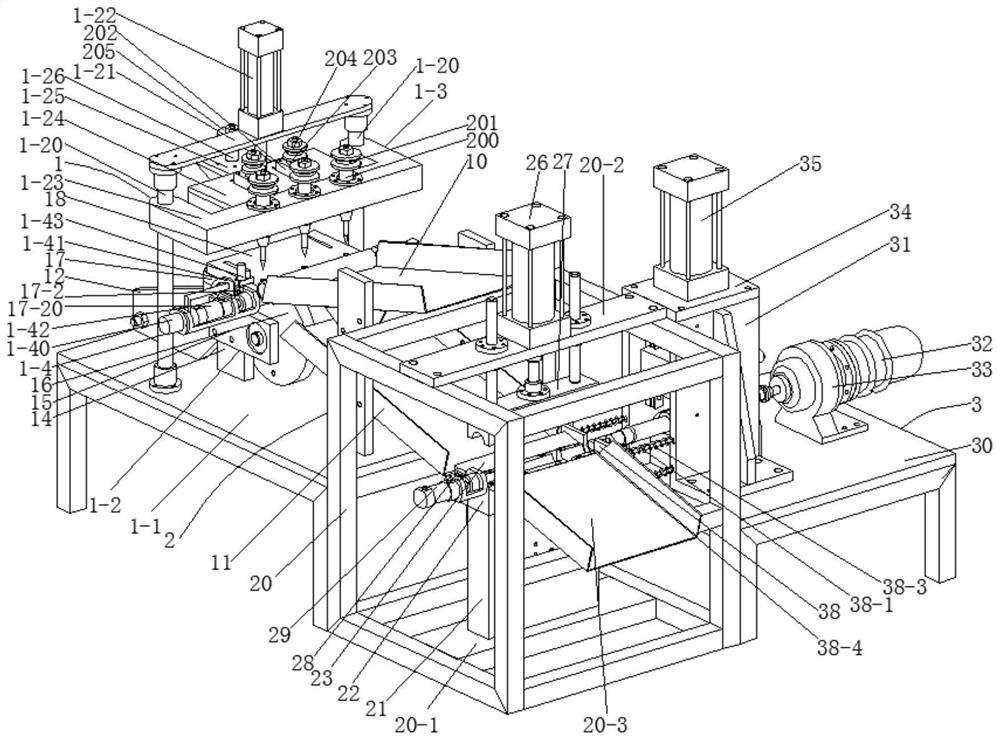

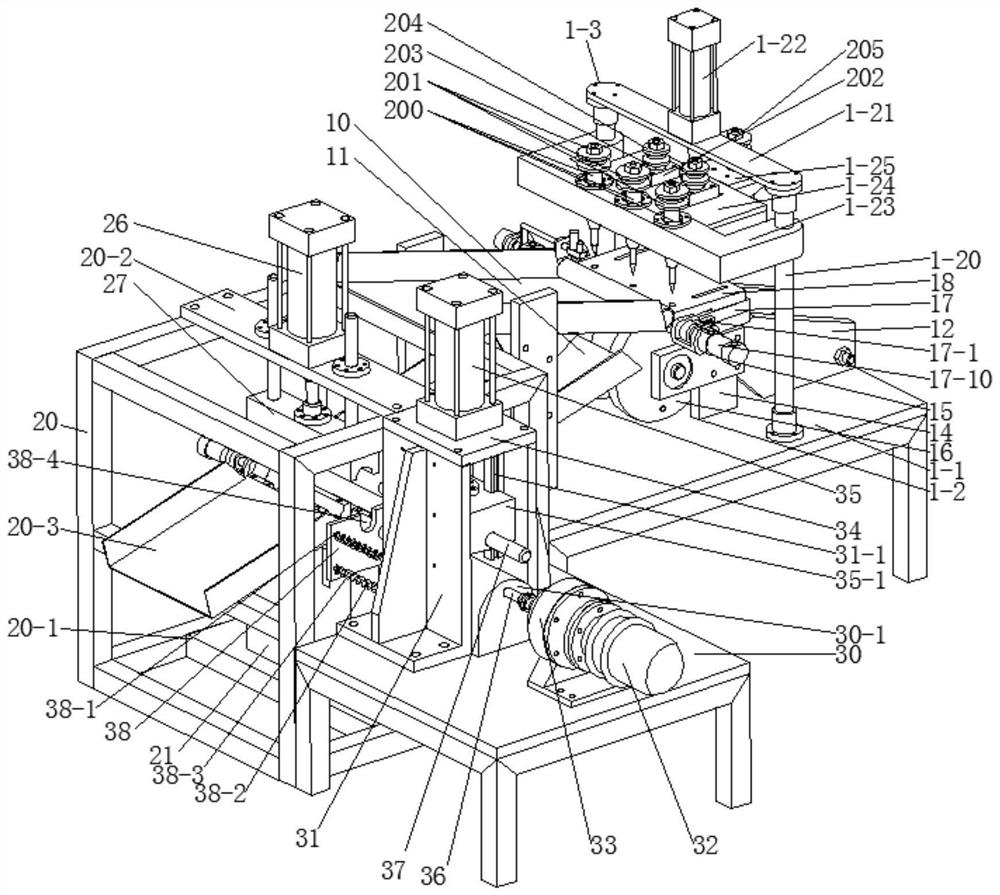

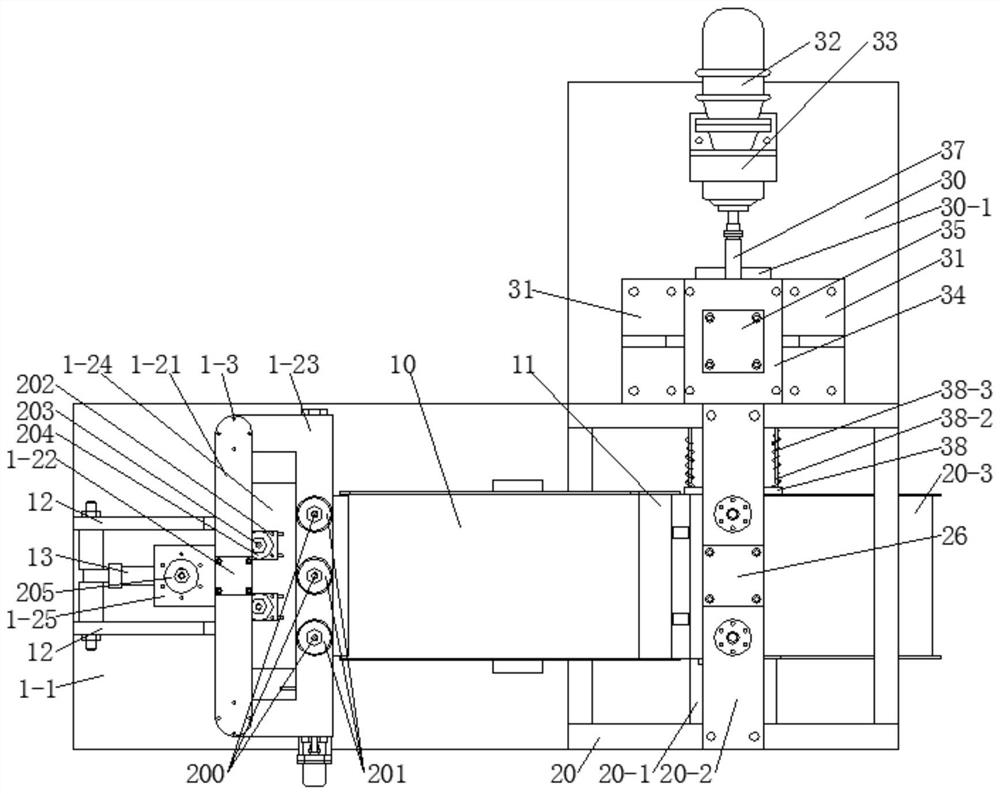

[0080] The pointer-type sprinkler irrigation pipe automatic drilling single-row hole shaping and hoop-pressing integrated machine of the present invention is mainly divided into the following steps: automatic loading and unloading, drilling single-drilling water holes, straightening and shaping, and pressing rollers.

[0081] The water discharged from the drill list with automatic loading and unloading:

[0082] First put the unloaded equal-length irrigation pipe into the feeding chute 10 of the automatic loading and unloading mechanism 1-2, and then the piston rod of the cylinder one 13 stretches out, and drives the feeding tray assembly 16 to rotate an angle counterclockwise through the pin shaft , the V-shaped groove 16-4 on the feeding tray 16-3 substitutes the irrigation pipe at the bottom of the feeding trough member 10 under the upper limit plate 18, and is limited by the circumferential limit plate 17.

[0083] Then, the piston rods of the compression cylinder 17-10 an...

Embodiment 2

[0098] On the basis of Embodiment 1, the material tray assembly 16 includes a material shaft 16-1, a material barrel 16-2 and a material tray 16-3. The material shaft 16-1 and the cantilever plate 15 are hinged through bearings. The material barrel 16-2 is sleeved in the middle of the material shaft 16-1, and two of the material trays 16-3 are arranged symmetrically with respect to the material barrel 16-2. The feeding shaft 16-1 rotates synchronously, the feeding plate 16-3 is provided with a V-shaped groove 16-4; the circumferential limit plate 17 is provided with a notch, the design of the V-shaped groove 16-4 , not only realizes the automatic loading and unloading operation, but also combines with the notch provided on the circumferential limit plate 17, so that the irrigation pipe is pressed against the piston of the cylinder 17-3 in the material tray assembly 16 and the circumferential limit plate 17 The friction resistance is small when the pressing head at the end of t...

Embodiment 3

[0100] On the basis of Embodiment 1, one side of the circumferential limit plate 17 is provided with a limit seat 17-1, the other side is provided with a second limit seat 17-2, and the first limit seat 17-1 is provided with a pressure Cylinder 1 17-10, the limit seat 2 17-2 is provided with compression cylinder 17-20, and the end of the piston rod of compression cylinder 1 17-10 and compression cylinder 17-20 is provided with a top pressure head; The irrigation pipe will not be thrown out along the axis direction of the irrigation pipe when the drill bit at the lower end of the drilling shaft 200 is cutting, so as to ensure the safety of drilling multiple water outlet holes on the same busbar of the irrigation pipe.

[0101] The turning mechanism 1-4 includes a stepping motor 1-40, an arc-shaped slot limit frame 1-41, a rotating frame 1-42 and a miniature electric push rod assembly 1-43. The stepping motor 1-40 is connected with the The rear end of the second limit seat 17-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com