Simulation test system for core wall dam material rolling construction in winter in cold region

A simulation test system and simulation test technology, which are applied in the field of simulation test systems for the rolling construction of core wall dam materials in cold regions in winter, can solve the problems of high test labor and material costs, inability to reflect, and low reliability, and achieve high precision. Control, ensure measurement accuracy, reduce the effect of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

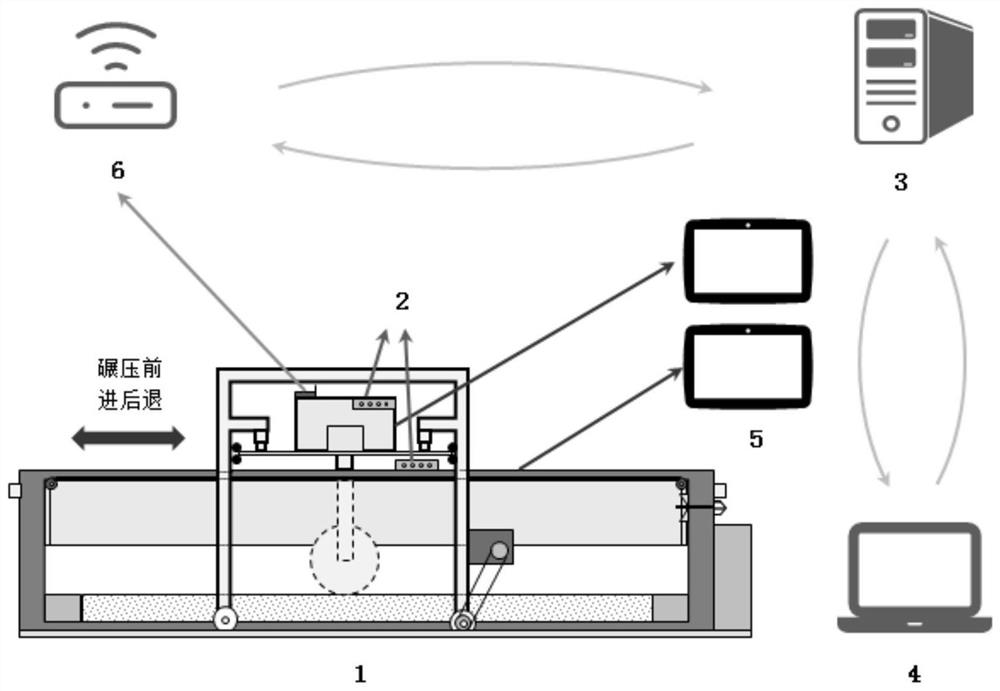

[0033] A simulation test system for rolling construction of core wall dam materials in cold regions in winter, including a temperature-controllable and wind-speed-controlled rolling construction simulation test device 1, an integrated controller 2, a database and application server 3, a monitoring client 4, and a display device 5 and the wireless communication module 6,

[0034] The roller compaction construction simulation test device 1 with controllable temperature and wind speed is used for roller compaction construction test;

[0035] The integrated controller 2 is used to collect and store various experimental information in the rolling construction test;

[0036] The database and application server 3 are used to store various experimental information in the rolling construction test collected by the integrated controller, and after analyzing the various experimental data, send control instructions to the integrated controller;

[0037] The monitoring client 4 is used to...

Embodiment 2

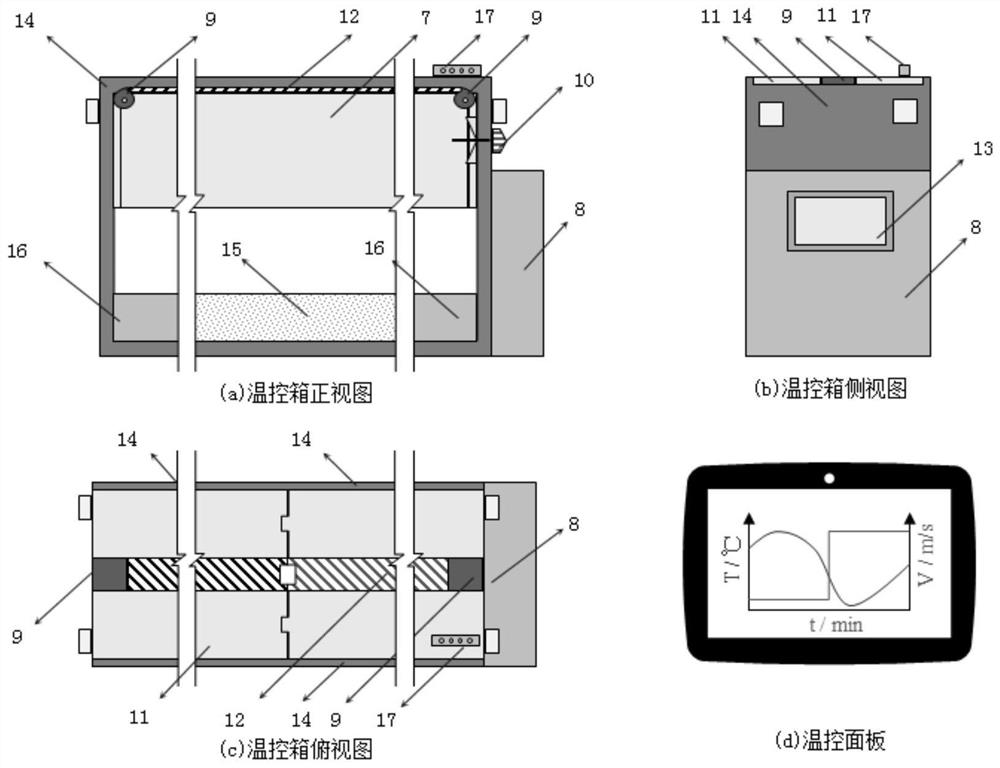

[0053] On the basis of the first embodiment, the rolling construction simulation test device with controllable temperature and wind speed includes a temperature control box, a rolling wheel system and a mobile device. Tracks 32 are opened on the ground on both sides of the temperature control box, and the mobile device is slidably installed. On the track 32, the roller system is mounted on the mobile device.

[0054] The temperature control box includes a box body, a temperature control unit 8, a semiconductor refrigeration sheet 7, an automatic unwinding and rewinding machine 9, a circulating fan 10, a switch door 11, a thermal insulation strip 12 and an integrated controller 17, which are installed on the top side of the box body. The integrated controller 17, the opening and closing door 11 is installed in the middle of the top of the box body, the circulation fan 10 is installed on one side of the box body, and the circulation fan 10 is used to guide the air flow to achieve...

Embodiment 3

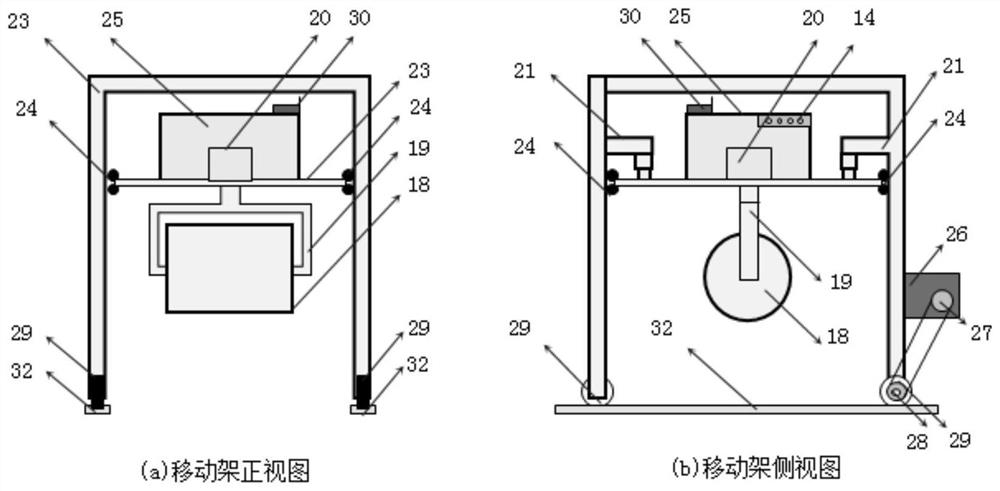

[0058]On the basis of the second embodiment, the moving device includes a carrier frame 20 , a lifting device 21 , a frame 22 , a moving frame body 23 , a main driving device 25 , an auxiliary driving device 26 and a roller 29 , and the moving frame body 23 slides through the roller 29 Installed on the track 32, the lifting device 21 is installed on the moving frame body 23, and the rear end of the lifting device 21 is installed with the frame 22 to achieve the purpose of longitudinally moving the frame 22 along the moving frame body 23. The main drive device 25 is installed on the machine. On the frame 22, the load frame 20 is installed in the main drive device 25, so as to realize the purpose of carrying out the vibration compaction test of the rollers of different tonnage by adjusting the load of the load frame 20. On one side, a driving sprocket 27 is installed on the auxiliary driving device 25, and a driven wheel 28 is installed on the rolling shaft of the roller 29. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com