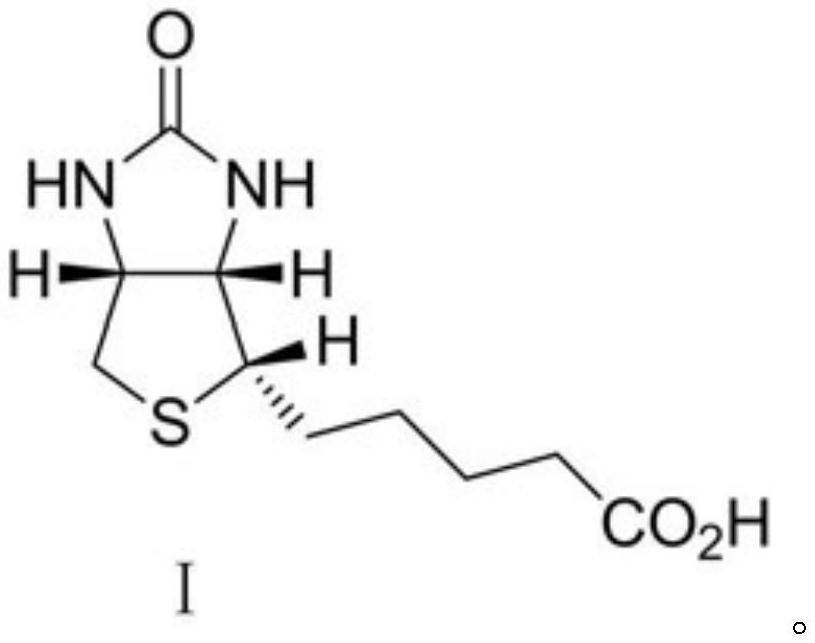

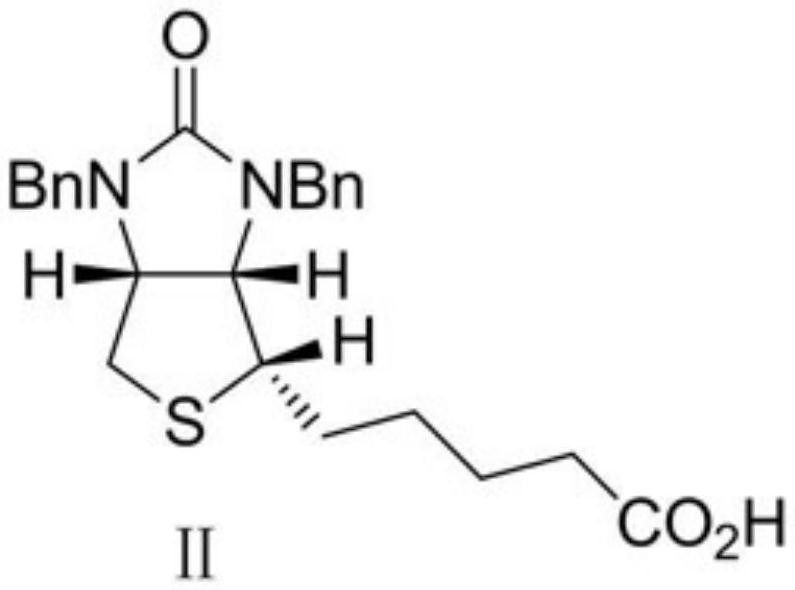

Biotin and preparation method thereof

A biotin and product technology, applied in the direction of organic chemistry and the like, can solve the problems of insufficient environmental protection, economy, difficulty in recovering benzyl bromide, etc., and achieve the effects of good commercial value, less burning residue and low heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of biotin, comprising the following steps:

[0033] (1) Preparation of product 1 and product 2: 100g of fumaric acid and 500mL of deionized water were added to the reaction kettle, heated to 120°C, slowly added dropwise with 100g of bromine, reacted at 120°C for 3 hours, and cooled to At room temperature, the solid product was obtained by filtration and drying; then 100 g of the solid product, 150 g of benzylamine, and 500 mL of toluene were added to the reaction kettle, and the reaction was carried out at 120 ° C for 6 h. White solid; 100g white solid, 1000g 30% liquid caustic soda are then added to the reactor to dissolve, and 500g massfraction is added dropwise simultaneously to be 30% two (trichloromethyl) carbonate toluene solution, in the dropping process, the dropwise temperature is controlled less than 80°C, after the dropwise addition was completed, the mixture was left to stand for stratification, the organic layer was distilled under redu...

Embodiment 2

[0043] A preparation method of biotin, comprising the following steps:

[0044] (1) Preparation of product 1 and product 2: 100g of fumaric acid and 500mL of deionized water were added to the reaction kettle, heated to 120°C, slowly added dropwise with 200g of bromine, reacted at 125°C for 2h, cooled to At room temperature, the solid product was obtained by filtration and drying; then, 100 g of the solid product, 200 g of benzylamine, and 500 mL of toluene were added to the reaction kettle, and the reaction was carried out at 125 ° C for 5 h. White solid; 100g white solid, 1200g 30% liquid caustic soda are added into the reactor to dissolve subsequently, and 800g massfraction is added dropwise simultaneously to be 35% bis(trichloromethyl) carbonate toluene solution, and the dropping temperature is controlled less than 80°C, after the dropwise addition was completed, the layers were left to stand, the organic layer was distilled under reduced pressure, filtered and dried to obt...

Embodiment 3

[0054] A preparation method of biotin, comprising the following steps:

[0055] (1) Preparation of product 1 and product 2: 100g of fumaric acid and 500mL of deionized water were added to the reactor, heated to 120°C, slowly added dropwise with 300g of bromine, reacted at 130°C for 1 h, cooled to At room temperature, the solid product was obtained by filtration and drying; then 100 g of the solid product, 250 g of benzylamine, and 500 mL of toluene were added to the reaction kettle, and the reaction was carried out at 130 ° C for 4 hours. White solid; 100g white solid, 1500g 30% liquid caustic soda are added into the reactor to dissolve subsequently, and 1000g massfraction is added dropwise simultaneously to be 40% bis(trichloromethyl) carbonate toluene solution, and the dropping temperature is controlled less than 80°C, after the dropwise addition was completed, the layers were left to stand, the organic layer was distilled under reduced pressure, filtered and dried to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com