Flip LED chip and production process thereof

A technology of LED chip and production process, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of poor thermal conductivity of flip-chip LED chips, falling off of flip-chip LED chips, and small contact area, so as to achieve good light extraction efficiency and prevent Detachment of virtual soldering and good interface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

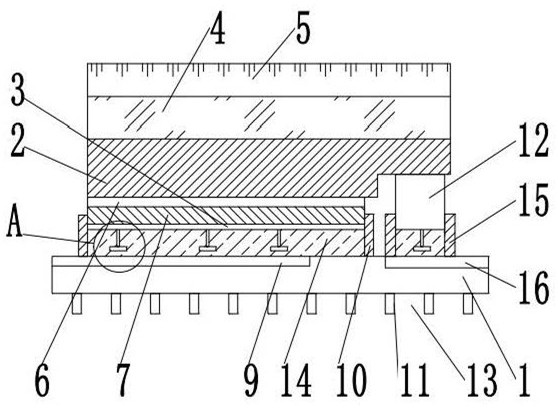

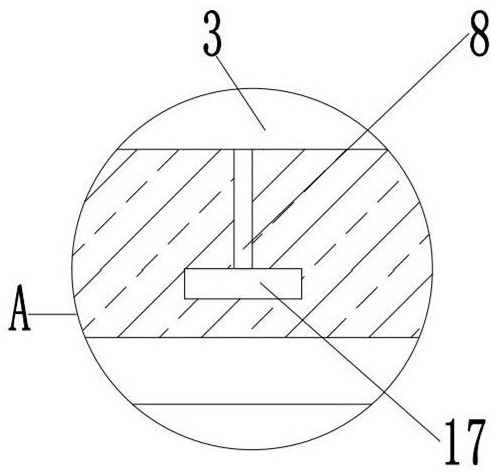

[0035] like Figure 1-3 As shown, a flip-chip LED chip provided by an embodiment of the present invention includes a substrate 1, an n-pole conductive plate 9 and a p-pole conductive plate 16 are embedded in the top of the substrate 1, and a positioning frame is welded on the top of the n-pole conductive plate 9 One 10, the top of the p-pole conductive plate 16 is welded with a positioning frame 2 15, the top of the substrate 1 is provided with a p-type gallium nitride layer 2, and the bottom outer wall of the p-type gallium nitride layer 2 is provided with an n-type gallium nitride layer 7 The bottom outer wall of the n-type gallium nitride layer 7 is provided with an n-electrode 3 , the n-type gallium nitride layer 7 is located inside the positioning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com