Power equipment maintenance system and method based on artificial intelligence

A technology of power equipment and artificial intelligence, applied in the field of deep learning, can solve problems such as the lack of a reliable control of the operating status of power equipment, the failure to arrange maintenance resources reasonably, and the inability to solve power equipment failure problems, so as to achieve reasonable maintenance resources and avoid The effect of overhaul and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

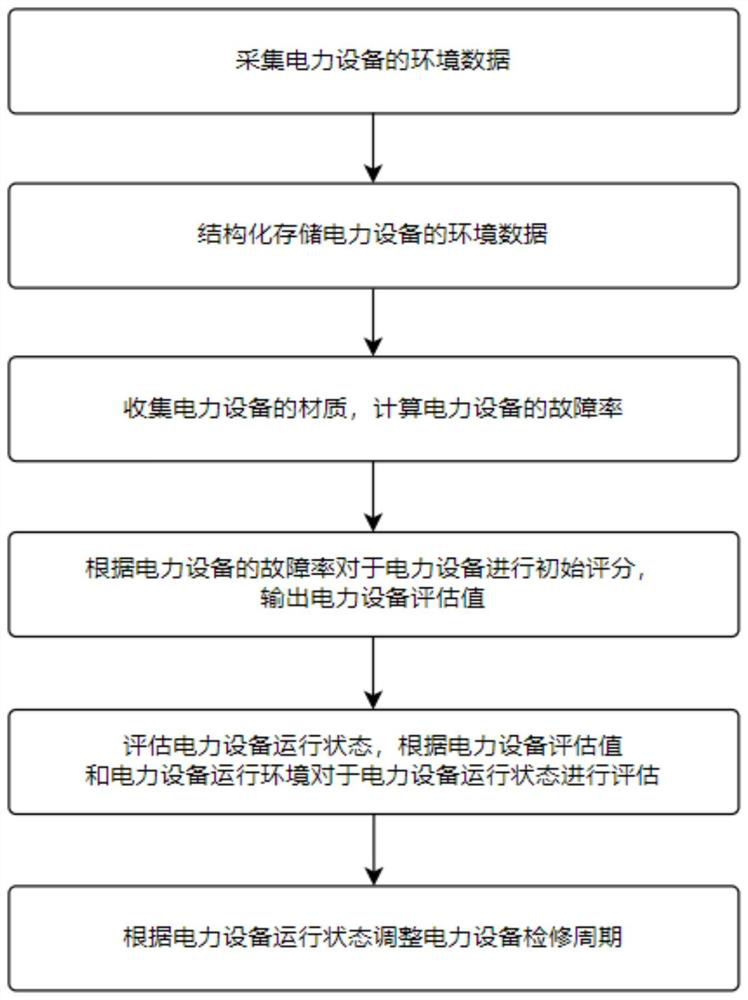

[0062] Embodiment 1: a power equipment maintenance system based on artificial intelligence, the power equipment maintenance system includes a power equipment environment acquisition module, an environmental data processing module, a power equipment evaluation module, a power equipment operation evaluation module and a power equipment maintenance unit;

[0063] The power equipment environment acquisition module collects the environmental data of the power equipment, and transmits the environmental data to the environmental data processing module;

[0064] The environmental data processing module receives the initial environmental data, performs data cleaning and data storage on the environmental data according to the stability of the environmental data acquisition equipment, further improves the accuracy of the environmental data, and ensures the accuracy of the evaluation by the power equipment operation evaluation module;

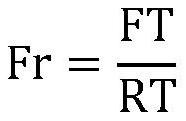

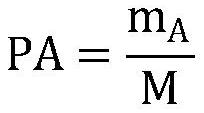

[0065] The power equipment evaluation module evaluate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com