Wafer defect analysis system

A defect analysis, wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc., can solve problems affecting wafers, wafers are not easy to find, error-prone, etc., to facilitate troubleshooting , saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

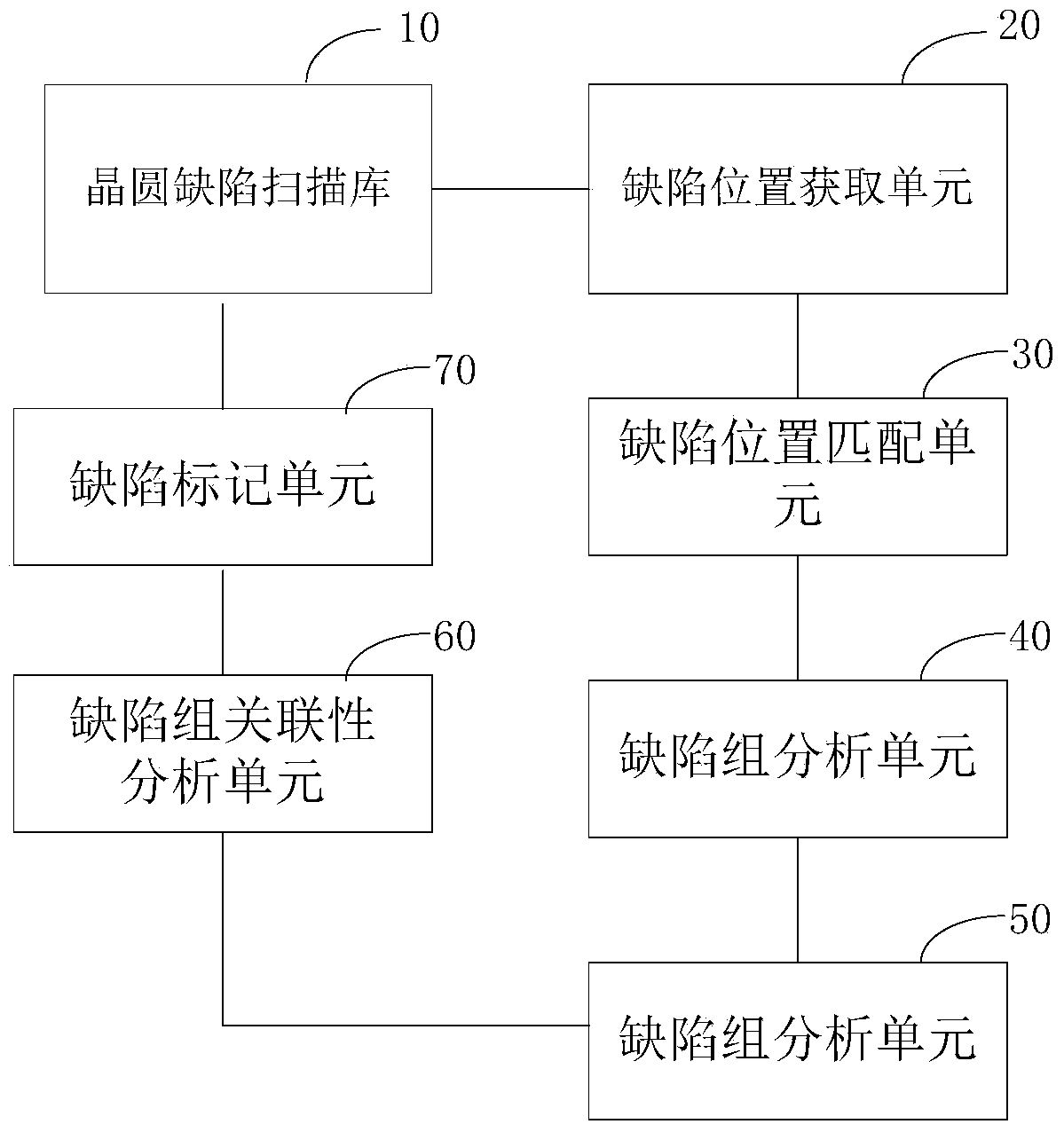

[0020] The problem to be solved by the present invention is to provide a wafer defect analysis system, which can analyze the scanning image of wafer defects, and highlight relevant defects, so as to facilitate timely investigation of the same defect at a specific position of the wafer.

[0021] In order to solve the above problems, a wafer defect analysis system of the present invention comprises:

[0022] The wafer defect scanning library is used to store the defect scanning diagrams of the wafers scanned by the wafer scanning machine within a set time, and the wafers include at least two batches of wafers;

[0023] A defect position acquisition unit, configured to obtain position information of defects based on the defect scanning diagram, and sort the position information, the position information includes an abscissa and a ordinate;

[0024] a defect position matching unit, configured to match the position information of a defect in the defect scan map of a wafer with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com