Manufacturing process of precious metal solid watch case

A production process and precious metal technology, applied in the field of precious metal solid watch case production process, can solve the problems that are difficult to apply to watch case manufacturing, and achieve the effect of improving stability and accelerating solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

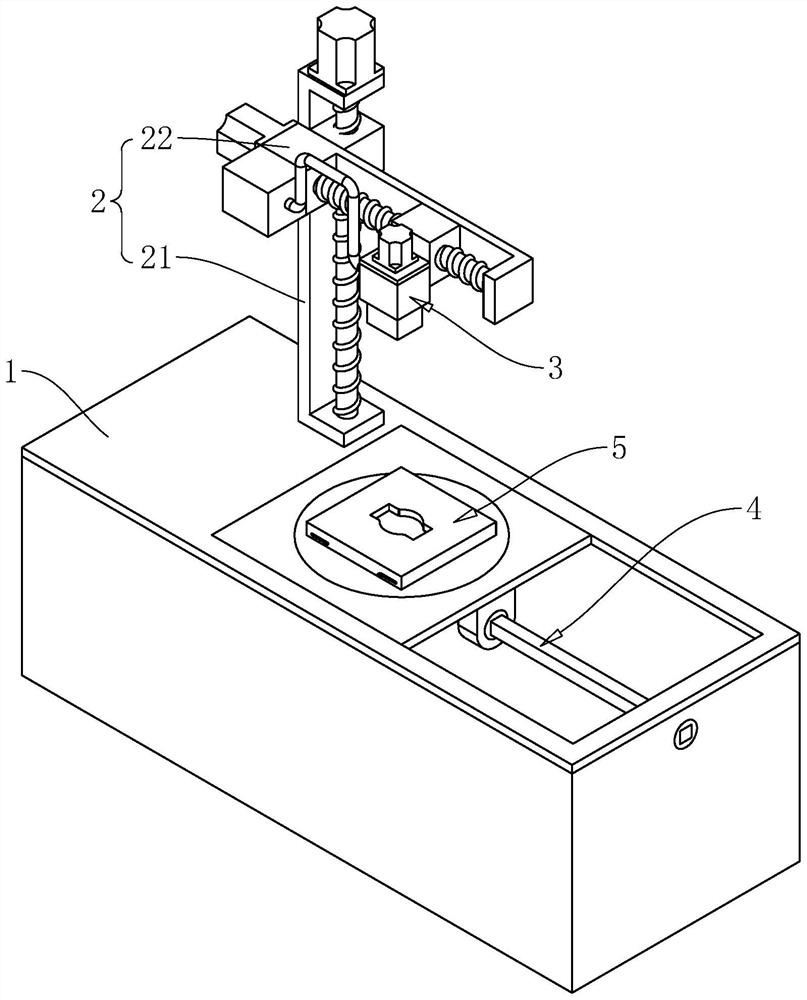

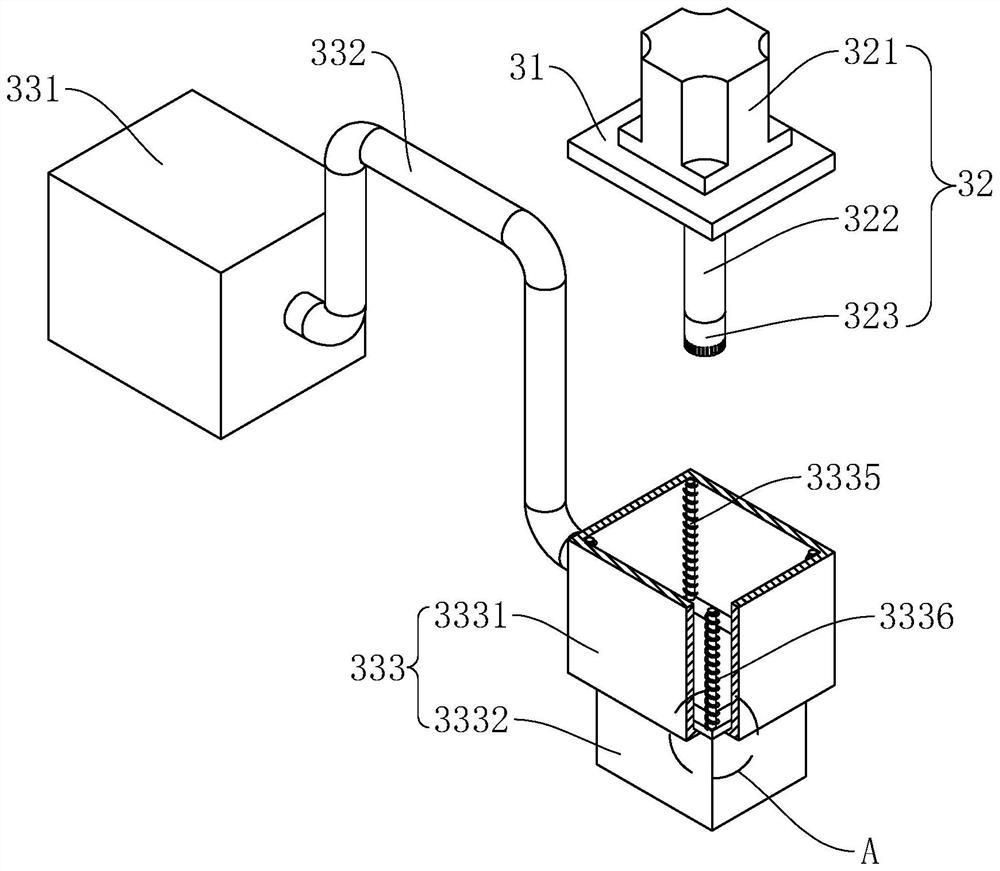

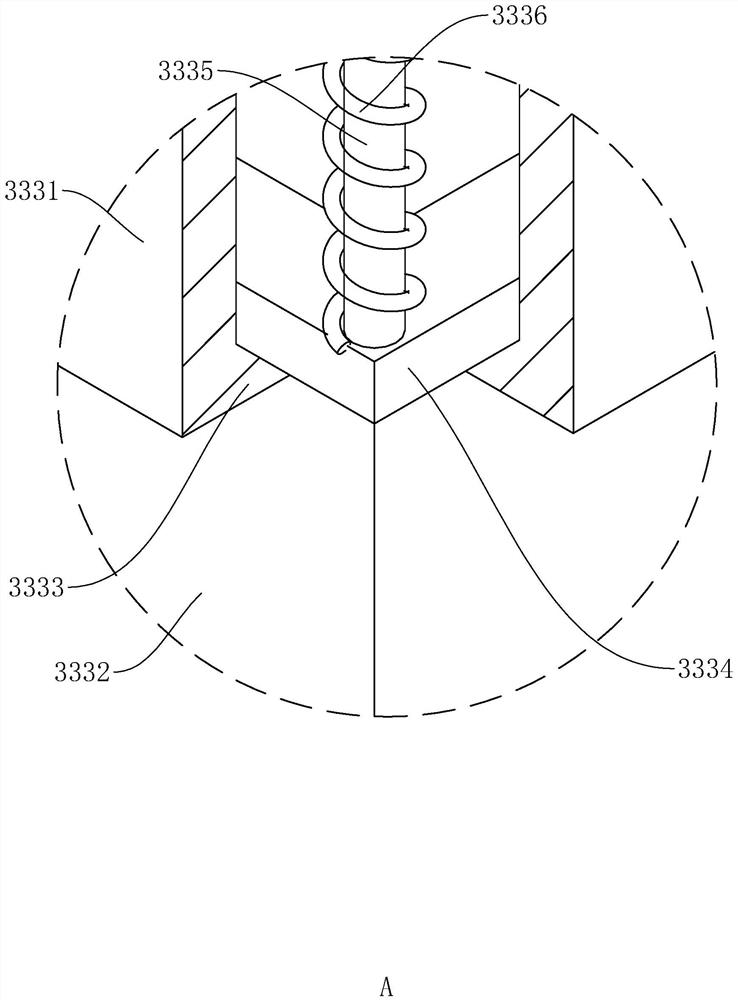

[0053] Attached to the following figure 1 -Attached Image 6 This application will be described in further detail.

[0054] The embodiment of the present application discloses a manufacturing process of a precious metal solid watch case. A manufacturing process of a precious metal solid watch case is implemented according to the following steps:

[0055] Step 1: Design a blank drawing for the product to be processed, design a mold according to the blank drawing and calculate the mass M of the product blank;

[0056] Step 2: Cut the precious metal into metal particles, install the mold on the rough blank machine, and electrically connect the mold with the rough blank, and deliver the metal particles from the feed port of the mold to the cavity in the mold according to the quality M;

[0057] Step 3: Heating the metal particles in the mold into molten metal, during the heating process, keep the air pressure in the cavity at 0.5atm-0.8atm;

[0058] Step 4: After the heating i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com